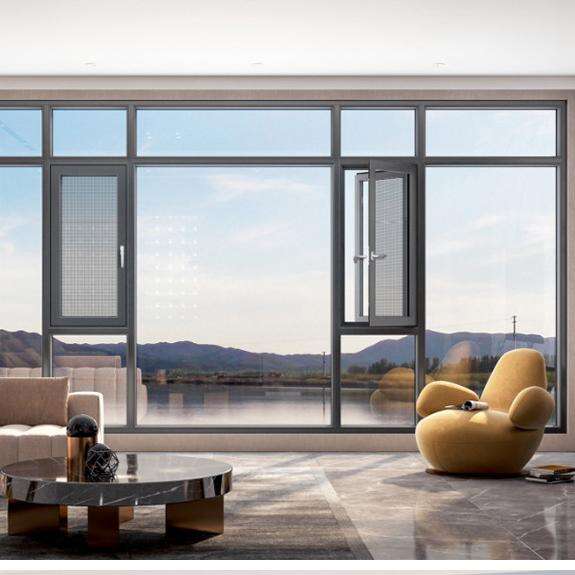

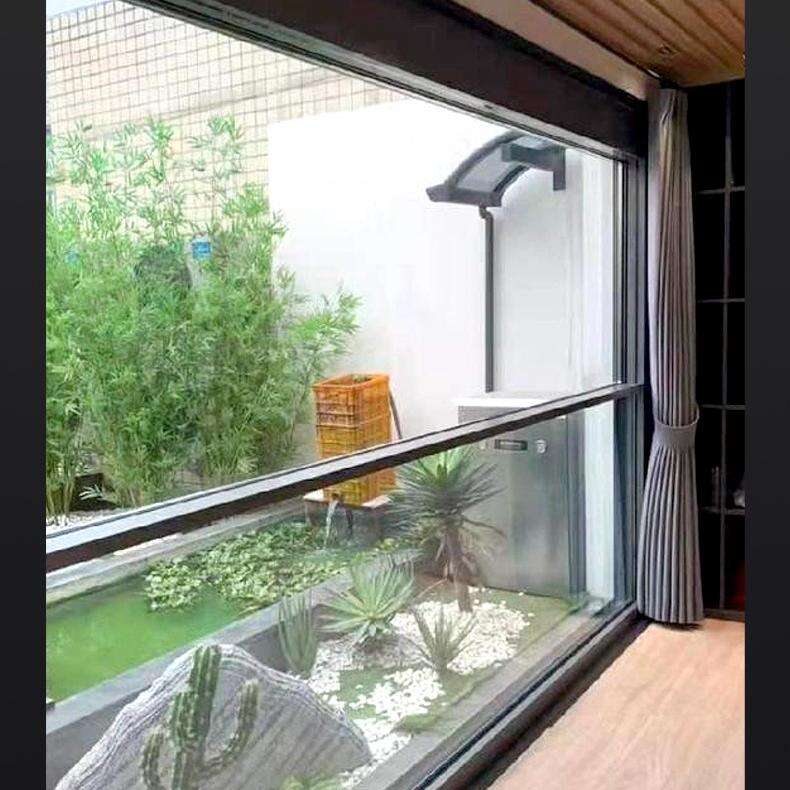

Надеждна конструкционна издръжливост и устойчивост на атмосферни условия

Изключителната инженерна изработка, осигурена от водещ доставчик на топлоизолирани алуминиеви врати и прозорци с откриване и плъзгане, гарантира забележителна дълготрайност и устойчивост на атмосферни влияния, които предпазват инвестицията в сградите в продължение на десетилетия. Напреднали алуминиеви сплави осигуряват превъзходно съотношение между якост и тегло, като запазват размерната стабилност при екстремни температурни колебания и околните условия. Доставчикът на топлоизолирани алуминиеви врати и прозорци с откриване и плъзгане използва алуминиеви сплави 6063-T5 и 6061-T6, специално подбрани за фасадни приложения, осигуряващи оптимално съчетание от якост, устойчивост на корозия и обработваемост. Прецизни процеси за екструзия осигуряват последователна дебелина на стените и структурна геометрия, отговаряща на строги инженерни изисквания за устойчивост на натоварване от вятър, сеизмична производителност и дълготрайност при термично циклиране. Напреднали варианти за повърхностна обработка, включително прахово напокряване, анодиране и флуорополимерни покрития, осигуряват изключителна защита срещу УВ деградация, морска вода и индустриални замърсители. Многостепенни предварителни обработки, включително почистване, етковане и конверсионно покритие, гарантират оптимална адхезия на покритието и дългосрочна производителност. Системи за уплътняване срещу времето включват множество защитни слоеве – първични уплътнения, вторични дренажни системи и камери за изравняване на налягането, които предотвратяват проникване на вода при екстремни метеорологични условия. Протоколите за структурни изпитвания потвърждават производителността при проектни натоварвания над 150 PSF, осигурявайки безопасност и надеждност в зони с силен вятър. Доставчикът прилага всеобхватни мерки за контрол на качеството, включително проверка на размерите, инспекция на повърхностната обработка и тестове за функционалност на фурнитурата. Напреднали системи за фиксиране на стъклата разпределят структурните натоварвания равномерно, като компенсират топлинното разширение и движението на сградата, без да се компрометира цялостта на уплътнението. Техниките за свързване в ъглите използват механични фиксатори, структурни адхезиви или заваръчни процеси, които запазват рамковата твърдост и устойчивост към атмосферни влияния през целия жизнен цикъл на продукта. Изпитванията за устойчивост на удар потвърждават съответствието с изискванията за урагани и сигурност, осигурявайки спокойствие на собствениците на имоти в зони със сериозни метеорологични условия. Графиците за поддръжка остават минимални поради вродената устойчивост на алуминия към корозия и висококачествените компоненти на фурнитурата, които работят гладко години наред без значително износване или необходимост от настройки.