How Thermal Break Technology Revolutionizes Aluminum Windows

Core Mechanics: How Thermal Breaks Minimize Heat Transfer

Thermal break tech cuts down on heat moving through aluminum windows, which makes them way more efficient when it comes to keeping energy costs low. Most people know aluminum conducts heat pretty well, so without any intervention, warmth just flows right through those frames, making buildings harder to keep comfortable. The solution? Thermal breaks usually crafted from something called polyamide. These work by placing a material that doesn't conduct heat between sections of aluminum. Basically, they stop the heat from traveling as freely as it normally would. What does this mean for homeowners? Lower bills at the end of the month. Research from various energy groups shows these breaks can cut heat transfer by around 40 percent in some cases. That kind of improvement adds up over time, especially during those long winter months when heating systems are working overtime.

Thermal breaks generally consist of a polyamide insulation layer sandwiched between aluminum components. Builders prefer polyamide because it works well as an insulator and lasts a long time without degrading. What makes this setup so effective is that it stops heat from moving through the material, which means homes stay warmer during cold months and remain cooler when temperatures rise. When installed in aluminum window frames, thermal break tech significantly boosts a building's insulation capabilities, leading directly to reduced heating and cooling costs over time. Anyone interested in seeing exactly how different manufacturers implement this technology should check out product specifications from companies specializing in thermal break aluminum windows.

Material Innovations in Polyamide Insulation Barriers

Recent improvements in how we formulate polyamides have really boosted their performance as insulators in those thermal break aluminum windows that are so popular these days. The newer versions provide better insulation against heat loss while also lasting longer than previous materials, which makes them pretty much the go-to option when trying to keep buildings at comfortable temperatures without wasting energy. Another big plus is that polyamide itself can actually be recycled multiple times over. This characteristic helps cut down on industrial waste significantly and means manufacturers aren't contributing as much carbon dioxide to the atmosphere during production runs. For companies looking to green up their operations, switching to recyclable polyamide options represents both an environmentally responsible move and a smart business decision in the long run.

Looking at real world examples shows just how much better buildings perform when new materials are used. Take polyamide insulation barriers for instance. Buildings that incorporate these modern barriers often see around a 30 percent boost in their thermal performance metrics. What does this mean practically? Less energy wasted keeping spaces comfortable. The numbers tell a story about both money saved on utility bills and lower carbon footprints across the board. Construction firms reporting these results also mention noticeable differences in occupant comfort levels during extreme weather conditions.

To learn more about these advances, consider exploring offerings from manufacturers renowned for producing high-quality thermal break aluminum windows, many of whom integrate advanced polyamide barriers in their products.

Casement vs. Sliding: Operational Advantages Compared

Casement Mechanics: Superior Seal for Extreme Climates

Casement window designs create better protection against air and water getting inside, which makes these windows great choices for areas with tough weather conditions. These windows work using hinges so the sash actually presses tightly against the frame when shut. Sliding windows are different because they slide along tracks, and this setup often lets some air or water get through over time. When there's bad weather like storms or heavy downpours, casement windows act as stronger barriers against both wind and rain, keeping homes comfortable inside and helping protect the building itself. According to research done by the National Fenestration Rating Council, casement windows tend to score much better on performance tests compared to sliding ones across different climate zones. This supports why many people choose casement windows for places where weather can be unpredictable.

Sliding Systems: Space Efficiency in Compact Areas

When it comes to saving space, sliding windows really shine, especially in smaller rooms where every inch counts. The design runs along a horizontal track system, so they work great in spots where traditional casement windows just won't fit because there's no room for them to swing out. Think about city apartments squeezed between other buildings – sliding windows let people keep their precious floor area intact while still getting that nice view and letting sunlight pour in. Plus, most folks find these windows super easy to open and close. That matters a lot in tight corners of the house and makes life easier for anyone who struggles with mobility issues or limited hand strength.

Weather Resistance Comparison: Wind Load Performance

When picking out windows for places where strong winds are common, knowing about wind load ratings makes all the difference. Basically, these ratings tell us how well a window holds up under pressure before getting damaged something every homeowner should know if they live somewhere that gets hit by storms regularly. Casement windows tend to perform better against wind loads than sliding ones because of how they're built the way they seal shut creates much stronger protection against gusts. According to data from manufacturers in the window industry, even though both kinds can technically reach certain wind load standards, casement models really stand out in situations where extra strength matters most. Most professionals will tell anyone looking at replacement windows to think about what kind of weather patterns affect their area plus any special building requirements before deciding on either type. After all, nobody wants to replace windows again soon just because they didn't pick the right option for local conditions.

Energy Efficiency Metrics for Thermal Break Windows

Understanding U-Factors and Solar Heat Gain Coefficients

When looking at window energy efficiency, two key numbers stand out: U-factors and solar heat gain coefficients, or SHGC for short. The U-factor basically tells us how good a window is at keeping heat inside during cold weather, whereas SHGC looks at how much sunlight comes through and turns into heat inside our homes. Many modern aluminum doors and windows now include something called thermal break technology. This innovation adds an extra layer of insulation between parts of the frame, which makes a real difference in performance. We can see this effect clearly when we compare standard windows with those featuring thermal breaks side by side. The National Fenestration Rating Council has been doing extensive testing on all sorts of windows for years now, and their data backs up what manufacturers claim about improved efficiency with these advanced materials and designs.

Triple-Pane vs. Double-Pane: Climate-Specific Solutions

Triple pane windows give homeowners a real edge compared to their double pane counterparts, especially when living in places with harsh winters or scorching summers. The extra layer of glass combined with those gas filled gaps between panes makes these windows much better at keeping heat inside during winter months and blocking out summer heat. The US Department of Energy actually found that folks in cold climates could cut their heating bills by around 30% after switching to triple glazing. For anyone dealing with big temperature swings throughout the year, going triple is generally worth considering. While they do come with a higher price tag initially, most people find that their monthly energy savings start making up for the extra cost within just a few years. Homeowners interested in green building practices often see this as a smart long term investment despite the initial expense.

Architectural Integration and Design Flexibility

Minimalist Sightlines for Contemporary Aesthetics

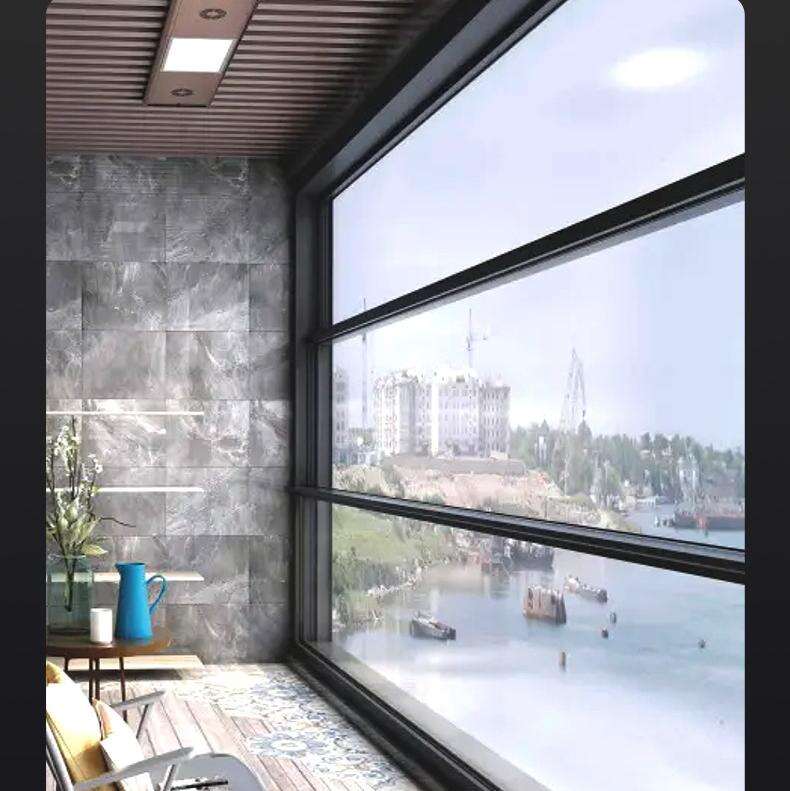

Minimalist design has become all the rage lately, which makes thermal break aluminum windows a smart choice for many projects. What sets them apart is their slim frames that let in more view without compromising strength. Architects really appreciate this because they want to make sure buildings have those wide open spaces where people can see outside clearly. The thermal break tech actually works wonders here too. It creates those super narrow window profiles that stop heat from transferring through the metal, so buildings stay both beautiful and efficient on energy bills. As Dean Ruark points out, aluminum just fits what designers need today. There's almost no limit to how clean and open these windows can look while still holding up over time. Shrinking those frames down but keeping everything sturdy means these windows hit the sweet spot for anyone looking to incorporate modern design elements into their spaces.

Custom Color Matching for Historic Renovations

Getting the colors right matters a lot when trying to keep old buildings looking their original best. Thermal break aluminum windows come in all sorts of colors, which helps restorations look good while still being energy efficient. There are different finish options too anodized, wet applied, and powder coated finishes that let these windows match up nicely with whatever building they go into. We've seen this work really well in European restoration projects where matching the exact historical color was crucial for approval from preservation boards. Architects love working with these windows because they can meet today's performance standards without sacrificing the look that made the building special in the first place. Most importantly, getting that balance right between new tech and old style keeps preservation projects from feeling out of place or rushed.

Durability and Maintenance Considerations

Corrosion Resistance in Coastal Environments

Saltwater corrosion remains a big problem for construction materials in coastal areas where buildings are constantly exposed to moisture and minerals. Aluminum frames with thermal breaks stand out as particularly resistant to these corrosive effects. Thermal breaks do double duty here they boost energy savings while also strengthening aluminum structures by preventing direct contact between metal parts, something that typically leads to rust issues over time. There's also a range of protective options available for aluminum surfaces, including things like anodization processes or powder coating applications that help prolong window life when installed near beaches or seaside locations. Field tests indicate that well-maintained aluminum retains both strength and good looks despite years of exposure to tough marine climates, which explains why so many architects specify it for beachfront properties and commercial developments right next to the ocean. Most professionals in the building trade will tell anyone listening that aluminum just holds up better than alternatives when dealing with salty sea air.

30-Year Lifespan: Recyclability of Aluminum Systems

When it comes to eco friendly options, aluminum windows really stand out because they last so long and can be recycled again and again. Most other window materials don't hold up quite as well over time, but properly maintained aluminum frames can stick around for around 30 years without losing their structural integrity or performance qualities. What makes aluminum truly special from an environmental standpoint is how easily it recycles. About three quarters of all aluminum made throughout history is still somewhere in circulation right now. The energy savings are mind blowing too recycling used aluminum takes just 5% of what it originally took to produce new material. This dramatically cuts down on both energy usage and the amount of waste ending up in landfills. And let's face it, nobody wants to see more trash piling up when there's a better alternative available. With such impressive recycling rates, aluminum plays a big part in circular economy initiatives. When builders select aluminum systems for their projects, they're getting durable products that will serve for decades while simultaneously helping create a greener planet aligned with various green building certification programs.