Anpassungsmöglichkeiten und Designflexibilität

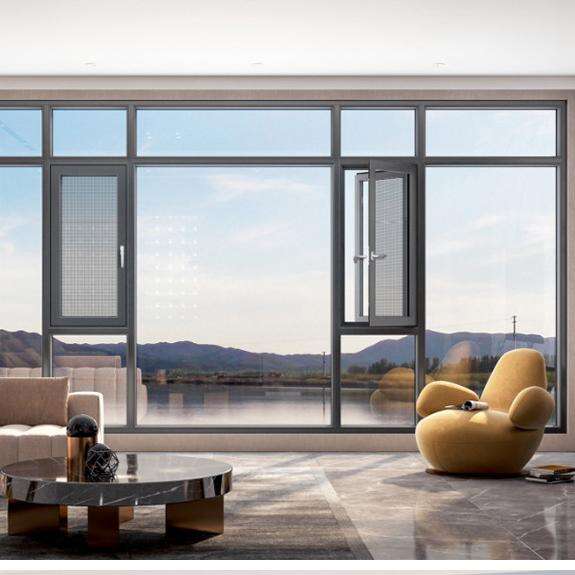

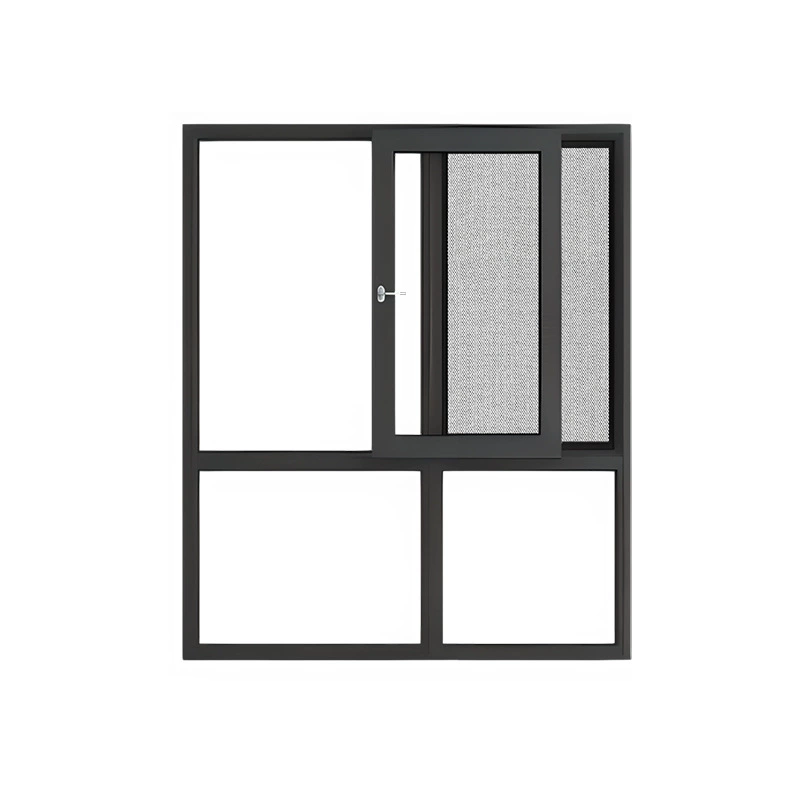

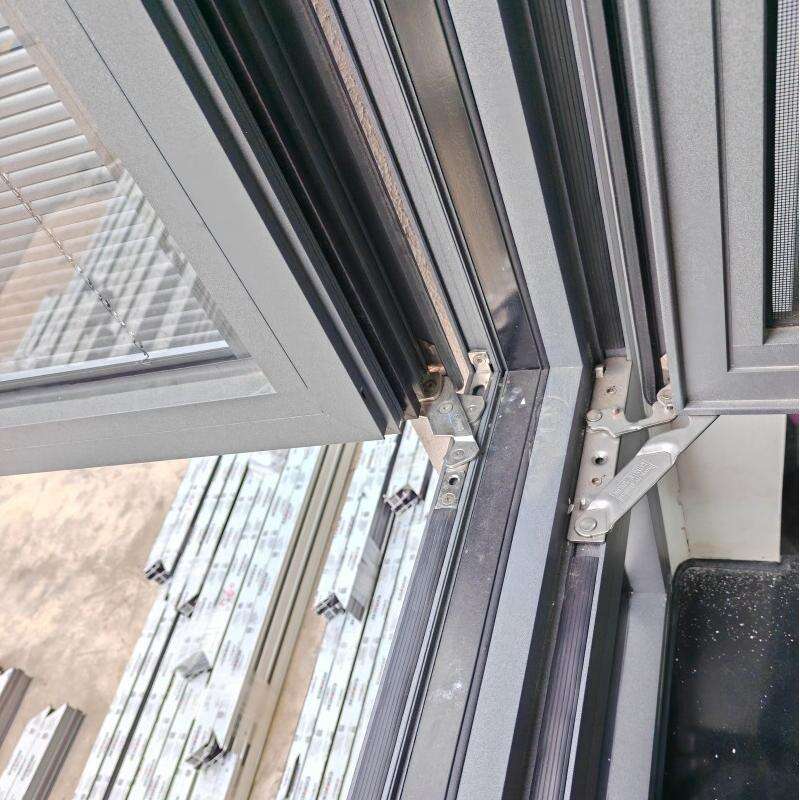

Der besondere Vorteil einer Zusammenarbeit mit einer etablierten Fabrik für thermisch getrennte Aluminiumtüren und -fenster für Villen liegt in den umfangreichen Anpassungsmöglichkeiten und der gestalterischen Flexibilität, die es Architekten und Hauseigentümern ermöglichen, ihre individuellen architektonischen Visionen zu verwirklichen, während gleichzeitig höchste Standards hinsichtlich der Wärmedämmung gewahrt bleiben. Professionelle Produktionsstätten verfügen über umfassende Bibliotheken von Aluminiumprofilen in verschiedenen Tiefen, Ausführungen und Konstruktionen, die unterschiedlichsten architektonischen Stilen gerecht werden – von zeitgenössischer minimalistischer Ästhetik bis hin zu traditionellen klassischen Proportionen. Die Farbanpassung geht weit über Standardangebote hinaus, dank fortschrittlicher Pulverlackbeschichtungssysteme, die nahezu jede gewünschte Oberfläche erzeugen können, darunter metallische Effekte, strukturierte Oberflächen, Holzdekore und Sonderfarben, die perfekt auf bestehende architektonische Elemente abgestimmt werden können. Die Verglasungsoptionen stellen eine weitere Dimension der Anpassungsfähigkeit dar: Professionelle Fabriken für thermisch getrennte Aluminiumtüren und -fenster für Villen bieten Einfach-, Zweifach- und Dreifachverglasungen mit niedrigem Emissionsgrad, Argon-Gasfüllungen, warmen Kantenabstandhaltern sowie speziellen Glastypen an, darunter Verbundsicherheitsglas, gehärtetes Sicherheitsglas und dekorative Varianten mit Ätzungen, Bereifung oder eingearbeiteten Mustern. Die Auswahl an Beschlägen umfasst eine Vielzahl von Griffvarianten, Verriegelungssystemen, Scharnierausführungen und Bedienmechanismen wie Flügeltüren, Schiebe-, Falt- und Dreh-Kipp-Systeme, die die Funktionalität je nach Anwendungsbereich und Nutzerpräferenz optimieren. Die dimensionale Flexibilität ermöglicht die Realisierung großer Öffnungen, komplexer geometrischer Formen und integrierter Systeme, die mehrere Bedienarten innerhalb einer einzigen Installation kombinieren. Zu den professionellen Fertigungsmöglichkeiten zählt auch die Integration von Smart-Home-Technologien wie motorisierten Antrieben, integrierten Sensoren und Vernetzungssystemen, die eine Fernüberwachung und -steuerung über Smartphone-Apps ermöglichen. Der Entwicklungsprozess beinhaltet in der Regel kollaborative Beratungsleistungen, bei denen technische Spezialisten des Werks direkt mit Architekten und Bauunternehmen zusammenarbeiten, um Systemspezifikationen zu optimieren, Installationsherausforderungen zu lösen und eine nahtlose Integration in das Gesamtgebäudedesign sicherzustellen. Die maßgeschneiderte Fertigung erstreckt sich auf spezielle Anwendungen wie gebogene Profile, schräge Einbauten und komplexe Mehrfeldkonfigurationen, die mit handelsüblichen Standardprodukten nicht realisierbar wären. So können selbst anspruchsvollste architektonische Konzepte erfolgreich umgesetzt werden, ohne die hervorragenden Wärmedämmeigenschaften zu beeinträchtigen, die qualitativ hochwertige Produkte aus Fabriken für thermisch getrennte Aluminiumtüren und -fenster für Villen auszeichnen.