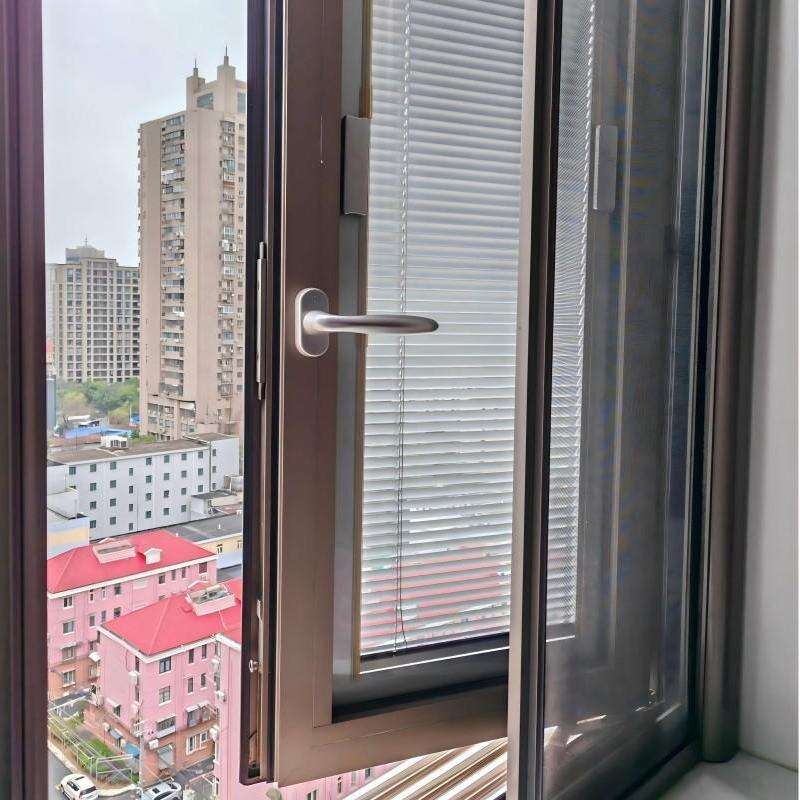

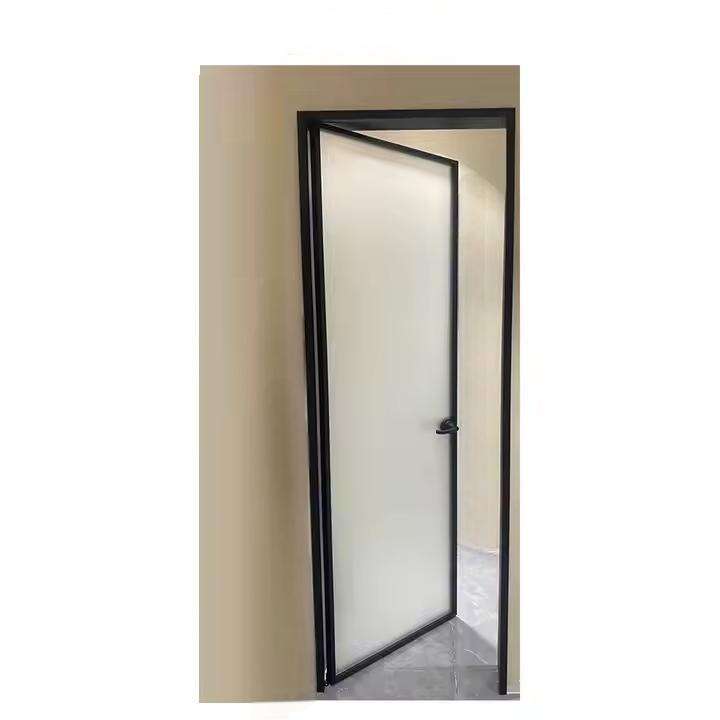

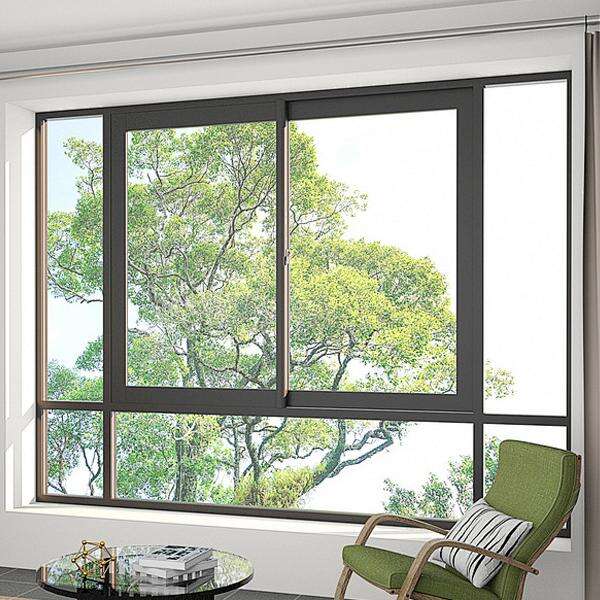

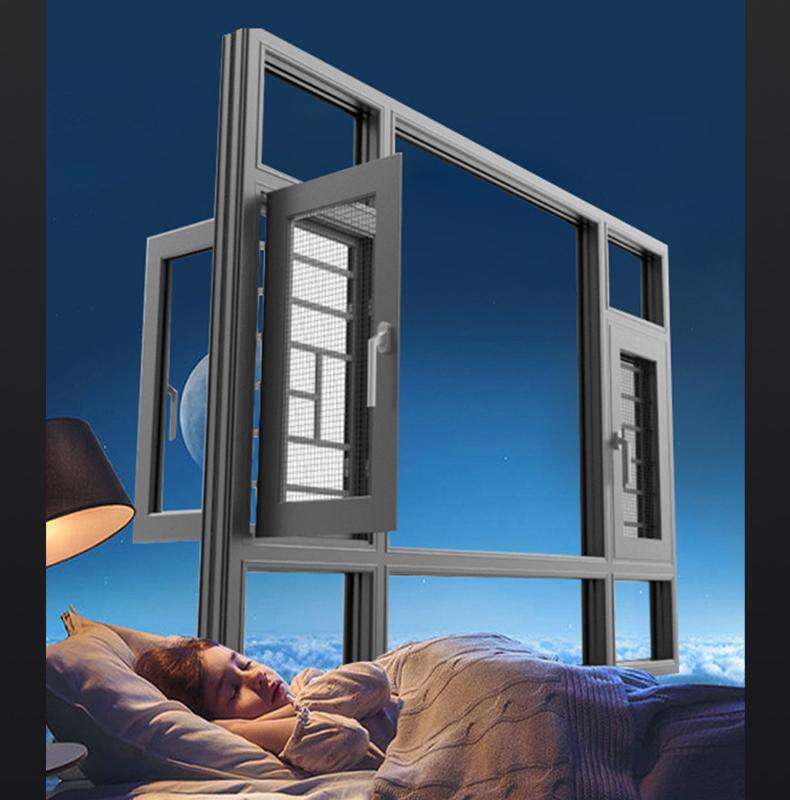

pabrikan pintu dan jendela aluminium casement sliding dengan pemutus termal

Seorang produsen pintu dan jendela aluminium casement sliding dengan thermal break mengkhususkan diri dalam memproduksi sistem fenestrasi canggih yang menggabungkan kinerja termal unggul dengan estetika desain modern. Para produsen ini fokus menciptakan solusi pintu dan jendela inovatif yang dilengkapi penghalang termal poliamida yang ditempatkan secara strategis di antara profil aluminium bagian dalam dan luar untuk mencegah perpindahan panas. Fungsi utama sistem ini adalah memberikan insulasi luar biasa sambil mempertahankan integritas struktural dan daya tarik visual yang ditawarkan oleh konstruksi aluminium. Fasilitas modern produsen pintu dan jendela aluminium casement sliding dengan thermal break menggunakan teknik produksi mutakhir, termasuk proses ekstrusi presisi, lini perakitan otomatis, serta protokol kontrol kualitas yang ketat. Fitur teknologinya mencakup desain profil multi-rongga yang meningkatkan efisiensi termal, sistem perangkat keras berpresisi tinggi untuk operasi yang lancar, serta pilihan kaca berkualitas tinggi yang memaksimalkan kinerja energi. Para produsen ini umumnya mengintegrasikan teknologi segel tahan cuaca, pelapisan permukaan tahan korosi, serta pilihan finishing powder coating yang dapat disesuaikan agar memenuhi berbagai kebutuhan arsitektural. Aplikasinya mencakup proyek konstruksi perumahan, pembangunan gedung komersial, fasilitas institusi, dan pasar renovasi, di mana regulasi efisiensi energi menuntut kinerja termal yang unggul. Produsen pintu dan jendela aluminium casement sliding dengan thermal break melayani arsitek, kontraktor, pembangun, dan pemilik rumah yang mencari solusi bangunan berkelanjutan guna mengurangi konsumsi energi sekaligus memberikan daya tahan jangka panjang. Kemampuan produksi sering kali mencakup opsi ukuran khusus, konfigurasi perangkat keras khusus, serta integrasi dengan teknologi bangunan pintar. Proses jaminan kualitas memastikan kepatuhan terhadap standar internasional dalam hal kinerja termal, integritas struktural, dan keandalan operasional, menjadikan produsen-produsen ini mitra penting dalam proyek konstruksi modern yang mengutamakan keberlanjutan lingkungan dan kenyamanan penghuni.