뛰어난 내구성 및 유지보수 이점

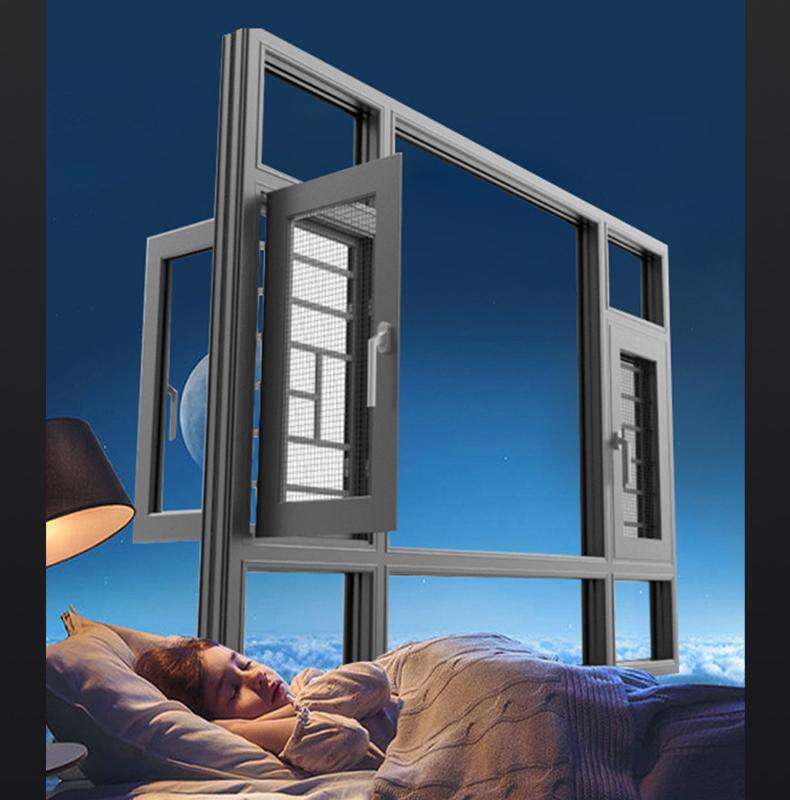

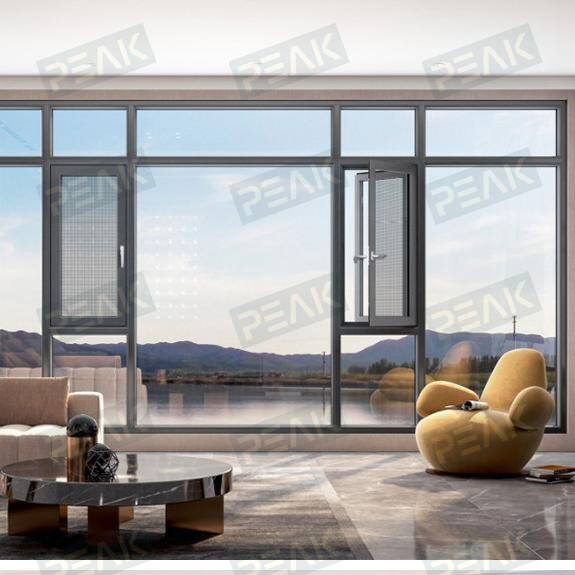

열절단 알루미늄 슬라이딩 창호는 뛰어난 내구성과 최소한의 유지보수 필요성 덕분에 장기적으로 뛰어난 가치를 제공하며, 수명 주기 비용 효율성과 지속적인 성능 신뢰성을 중시하는 건물 소유자에게 이상적인 선택이 됩니다. 알루미늄은 건축 자재로서 부식, 휨, 썩음 및 해충 피해에 자연스럽게 저항하는 특성을 가지며, 이는 다른 창호 재료에서 흔히 발생하는 문제들을 방지합니다. 또한 고급 분체 도장 마감 처리는 자외선, 습기, 대기 오염물질과 같은 환경적 요인으로부터 추가적인 보호막을 형성합니다. 이러한 부식 저항성은 염분이 많은 공기로 인해 열등한 재료가 급속히 손상되기 쉬운 해안 지역이나 화학 물질 노출로 인해 내구성이 낮은 창호 시스템의 구조적 무결성이 손상될 수 있는 산업 지역에서 특히 유리합니다. 알루미늄 프레임의 구조적 강도 덕분에 이 창호들은 시간이 지나도 비닐 또는 목재 프레임 시스템에서 발생할 수 있는 처짐이나 변형 없이 더 큰 유리 패널을 지지할 수 있어 정확한 정렬과 기밀성을 유지함으로써 수십 년에 걸친 사용 수명 동안 에너지 효율 성능을 지속적으로 유지합니다. 슬라이딩 열절단 알루미늄 창호의 정기 유지보수는 주기적인 청소와 움직이는 부품에 대한 간헐적인 윤활 작업으로 대부분 이루어지며, 이는 건물 소유자가 전문가의 도움이나 특수 도구 없이도 일반적으로 수행할 수 있습니다. 이러한 알루미늄 시스템에 적용된 분체 도장 마감은 다른 재료의 도장 표면보다 훨씬 우수한 색바램, 가루날림 및 풍화 저항성을 보이며, 리페인팅이나 교체 없이도 수년간 미적 외관을 유지합니다. 프레임 설계에 통합된 고급 배수 시스템은 습기 침투와 응축수를 효과적으로 관리하여 열등한 창호 시스템에서 발생할 수 있는 작동 문제나 구조적 손상을 유발하는 물 축적을 방지합니다. 열절단 구성 요소 자체도 뛰어난 안정성과 내구성을 보이며, 무수히 반복되는 열팽창 및 수축 사이클을 거쳐도 절연 성능과 구조적 무결성이 저하되거나 파손되지 않습니다. 품질 보증 시험 프로그램에서는 이러한 열절단 알루미늄 창호에 수십 년간의 정상 사용을 시뮬레이션하는 가속 노화 절차를 적용하여 장기간의 사용 기간 동안 성능 사양을 유지할 수 있는 능력을 입증하며, 건물 소유자나 유지보수 담당자의 최소한의 개입만으로도 지속적인 성능을 보장합니다.