iānis et fenestrae ex alūminiō cum frāgē durābilis et adaptātiōne

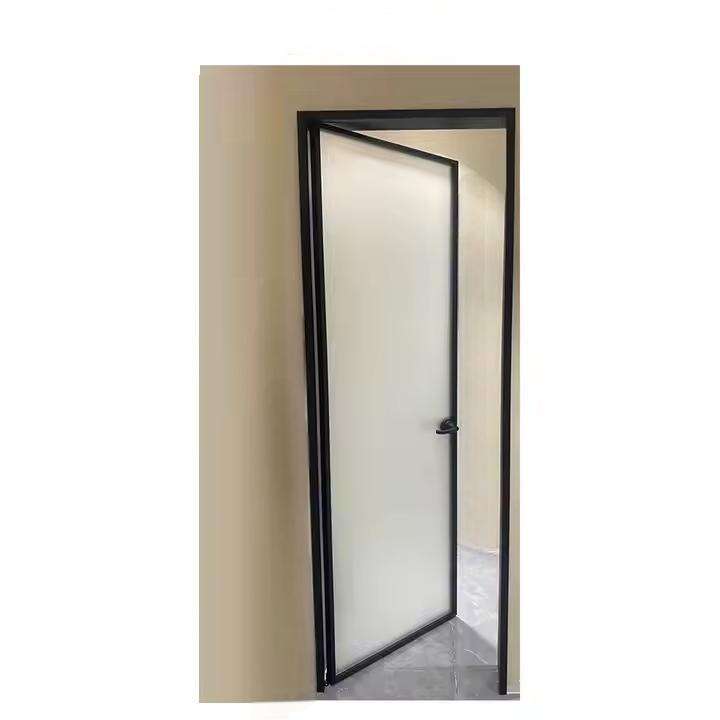

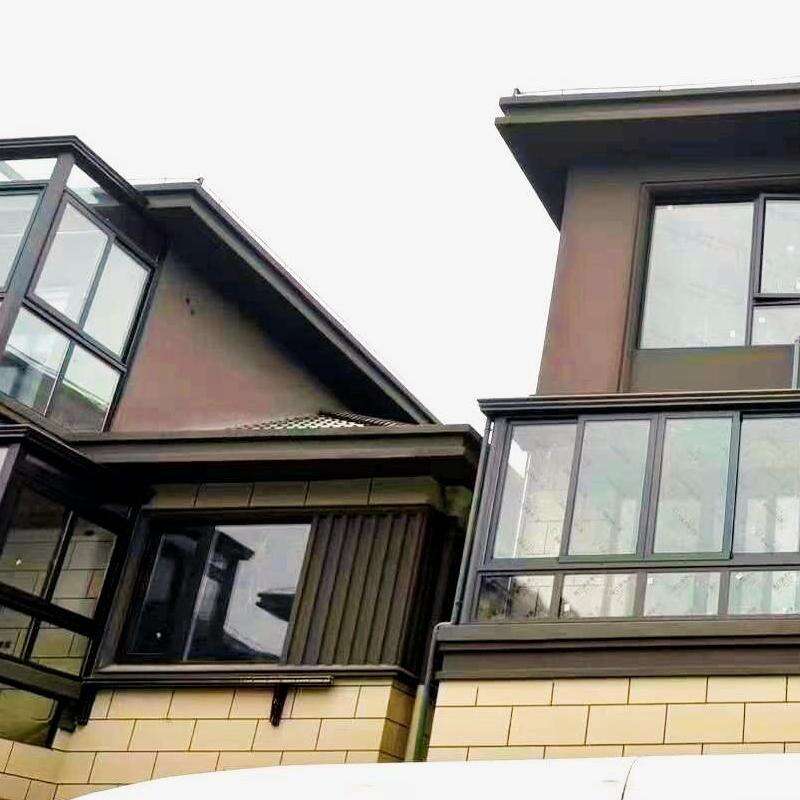

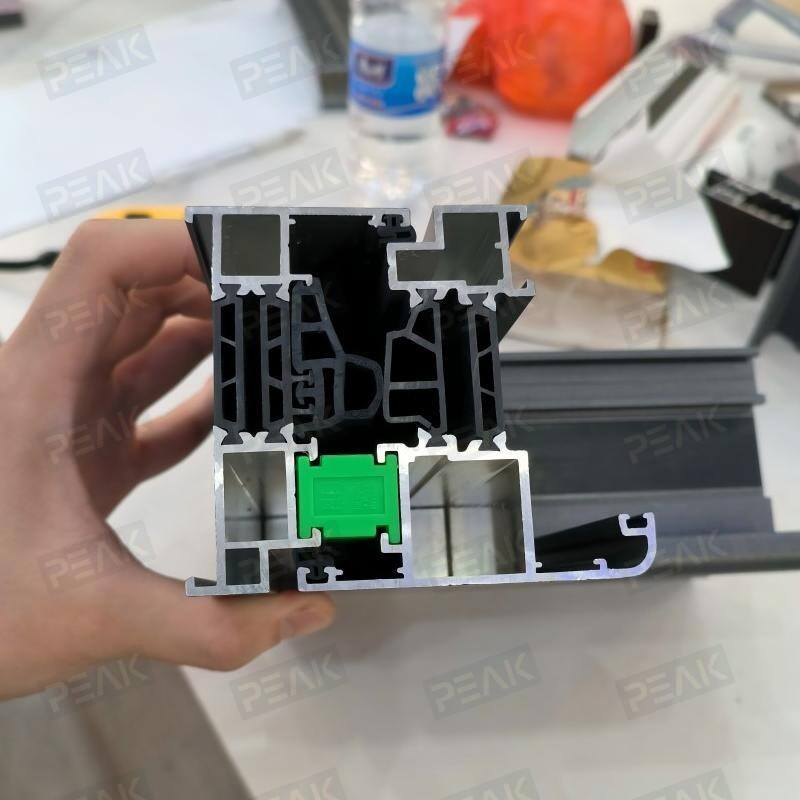

Durabiles fenestrae et ostia ex alluminio cum interruptione termica, ad mensuram facta, novum in solutionibus architecturalibus modernis repraesentant, quae summam efficientiam energetici cum praestanti durabilitate coniungunt. Haec technologia innovativa systema interpositionis thermicae includit, quod transferentiam caloris inter interna et externa elementa ex alluminio efficaciter interrumpit, creans valde efficientem barrierae isolationis. Technologia interrupturae thermalis utitur laminis ex polyamido vel similibus materiis insulativis strategicis locatis inter internas et externas structuras ex alluminio, praeventione pontis thermalis et retinendo temperaturis interioribus optimalibus per omnia tempora anni. Haec systemata ad mensuram parata, antea non cognita flexibilitate in designando offerunt, architectis et domus dominis permittentes solutiones singulares conficere, quae ad peculiaria requisita archiecturalia et aesthetica accommodatae sint. Processus fabricationis ostiorum et fenestrarum ex alluminio cum interruptione termica et durable ad mensuram, ingeniaria praecisam requirit, ubi unumquodque elementum secundum exactas specificatones fabricatur, machinis computatrici regitis usque ad altissima perfectionis puncta. Profila ex alluminio examinationibus qualitatis rigoris subiiciuntur, ut integritas structurae, resistentia adversus tempestates et normae perfomantiae thermalis certae sint. Designa plurium cammarum in structura teli proprietates isolationis augent, simul tamen levi pondere alluminii retento. Optiones vitrorum evolutae, binis aut ternis laminis comprehensae, technologiae interruptionis thermali adsunt, ut efficientia energetica maxima fiat. Systemata obsignandi meteoris multiplices stratos cunctorum et canales drenationis comprehendunt, qui infiltreationem aquae et effusionem aeris prohibent. Processus customizationis varias mechanismorum aperiendi formas admittit, inter quas sunt battentes, labentes, inclinantia-rotantes et fixae dispositiones. Tractationes superficiei, a pulvere picto usque ad anodizationem, amplita colorum genera et finitiones offert quae evanescere, corrumpi et frangi resistunt. Haec systemata tam in applicationibus domesticis quam mercatoriis excellunt, solutiones pro aedificiis altis, domibus pretiosissimis, emporiis et aedificiis industrialibus praebendo. Processus fabricationis conformitatem cum regulis aedificandi internationalibus et normis energetici certat, faciendo ut ostia et fenestrae ex alluminio cum interruptione termica et durable ad mensuram idealis electio sint pro aedificationibus sustinendis, quae longam durationem et fidem quaerunt.