енг юкни баҳоланган исиқ перехити бор алуминий дарваза ва жохарилар индивидуал ташкилот

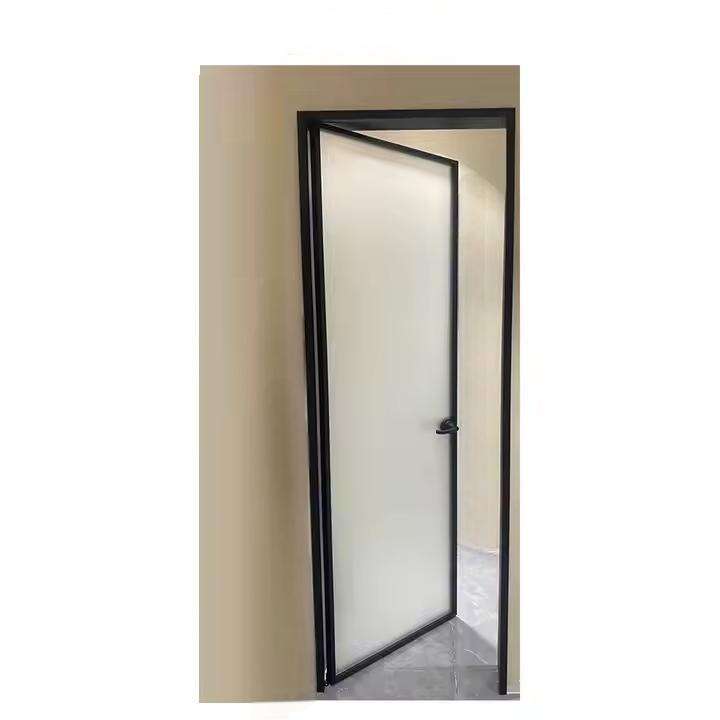

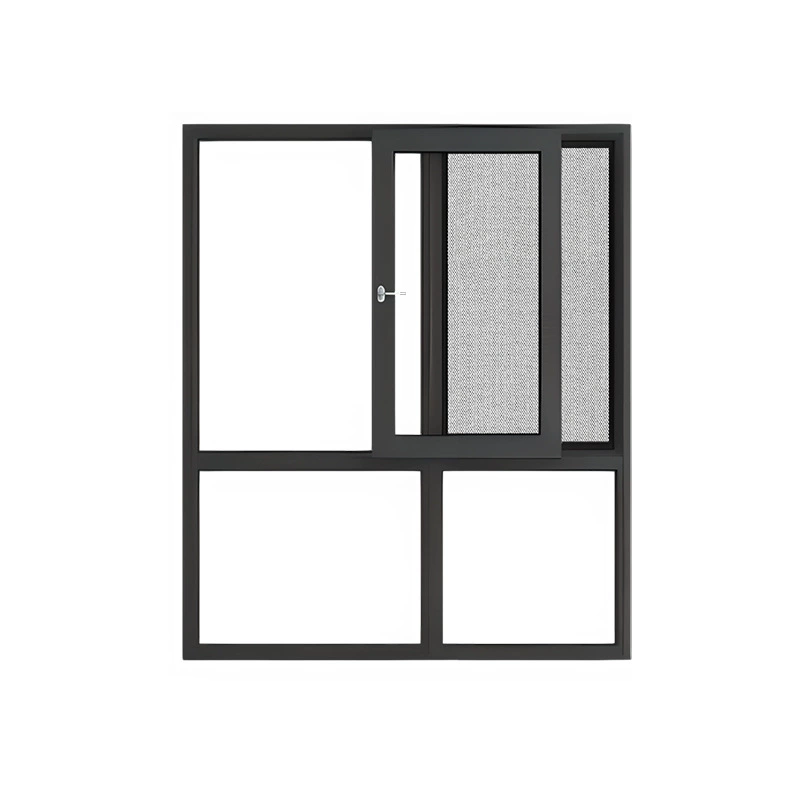

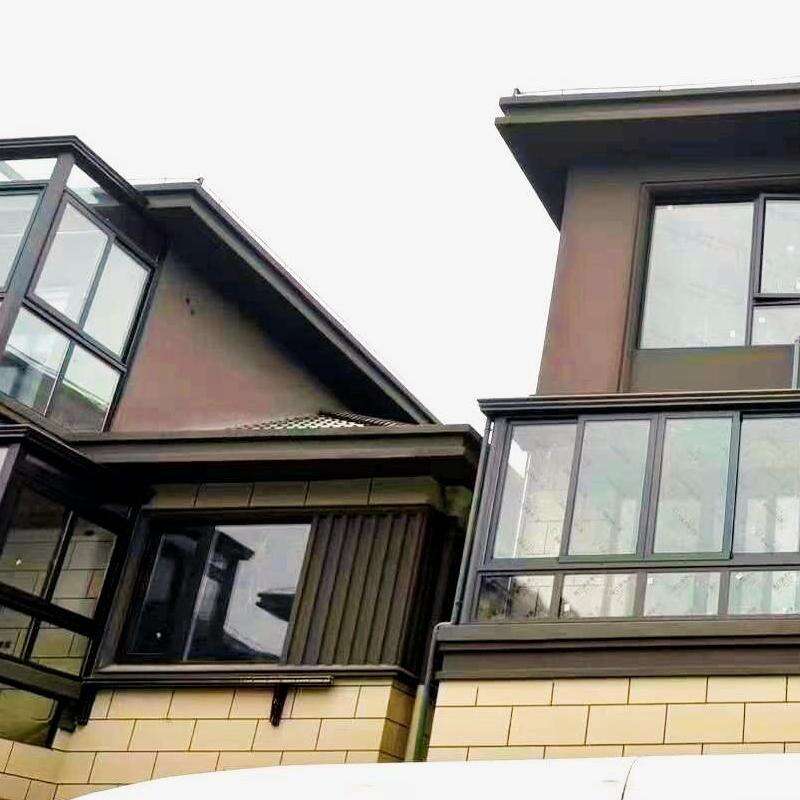

Eng yaxshi reytingdagi issiqlik uzilishli aluminiy eshiklar va derazalarni sozlash zamonaviy me'morlik dizayniga inqilobiy yondashuvni ifodalaydi, bu yerda ilg'or muhandislik bilan shaxsiylashtirilgan estetika birlashib, ajoyib ishlash hamda ko'zga yoqimli tashqi ko'rinish taqdim etiladi. Ushbu murakkab tizim ichki va tashqi aluminiy profillarni ajratib turuvchi issiqlik uzilish texnologiyasidan foydalangan holda issiqlik o'tishini oldini oladi hamda energiya samaradorligini sezilarli darajada oshiradi. Shaxsiylashtirish imkoniyati mulkdorlarga o'lchamlari, ranglar, qulflar tanlovi hamda shaffof panellar kabi barcha jihatlarni o'z ehtiyojlariga moslashtirish imkonini beradi. Yuqori sifatli yechimlarda aluminiy bo'limlari orasida strategik ravishda polyamid tolalar yoki boshqa izolyatsiya materiallari joylashtirilgan bo'lib, u ichki haroratni optimallashtirish hamda energiya iste'molini kamaytirish uchun issiqlik to'sig'ini yaratadi. Ishlab chiqarish jarayonida aniq muhandislik usullari qo'llaniladi, shu jumladan durduruvchi hamda ob-havo ta'siriga chidamli bo'lishi uchun maxsus ishlov berilgan yuqori sifatli aluminiy qotishmalardan foydalaniladi. Ilg'or changsimon plyonka qoplamalar esa qattiq atrof-muhit sharoitiga chidamli, uzodavom sifatli tashqi ko'rinishni saqlab turadi. Eng yaxshi reytingdagi issiqlik uzilishli aluminiy eshiklar va derazalar sozlanadigan tizimlari issiqlik samaradorligini, tovush izolyatsiyasini hamda konstruktiv mustahkamlikni optimallashtiruvchi ko'p xonalardan iborat dizaynga ega. Shaffof panellar past emissivli qoplamali ikki yoki uch qavatli tuzilmaga ega bo'lib, inert gazlar bilan to'ldirilgan holda yuqori izolyatsiya xususiyatlarini ta'minlaydi. Qulflar tarkibidagi komponentlar korroziyaga chidamli, mahsulotning butun foydalanish muddati davomida silliq ishlashini kafolatlaydigan tirnoqsiz po'lat hamda dengiz sifatidagi materiallardan tayyorlangan. Bu tizimlar zamonaviy minimalistik dizayndan tortib an'anaviy Yevropa estetikasigacha bo'lgan turli me'morlik uslublariga mos keladi hamda shaxsiy, tijorat hamda institutsional binolar uchun mos hisoblanadi. Sozlash jarayoni aniq loyiha talablari, atrof-muhit omillari hamda ishlash kutilishlari bo'yicha tahlil o'tkazib, issiqlik samaradorligi, xavfsizlik hamda ishlash ishonchliligi bo'yicha sanoat standartlaridan yuqori yechimlar yaratish uchun dizaynerlar bilan batafsil maslahatlarni o'z ichiga oladi.