шамолга мукос, сувга мукос термикс бозорчи айрим алуминий дарвазалар ва тондирма ишlab чиқузувчи

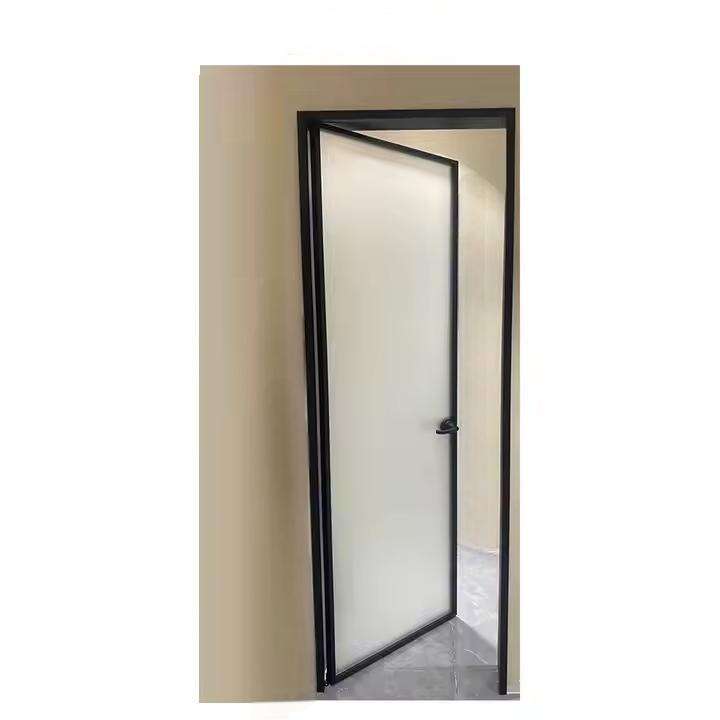

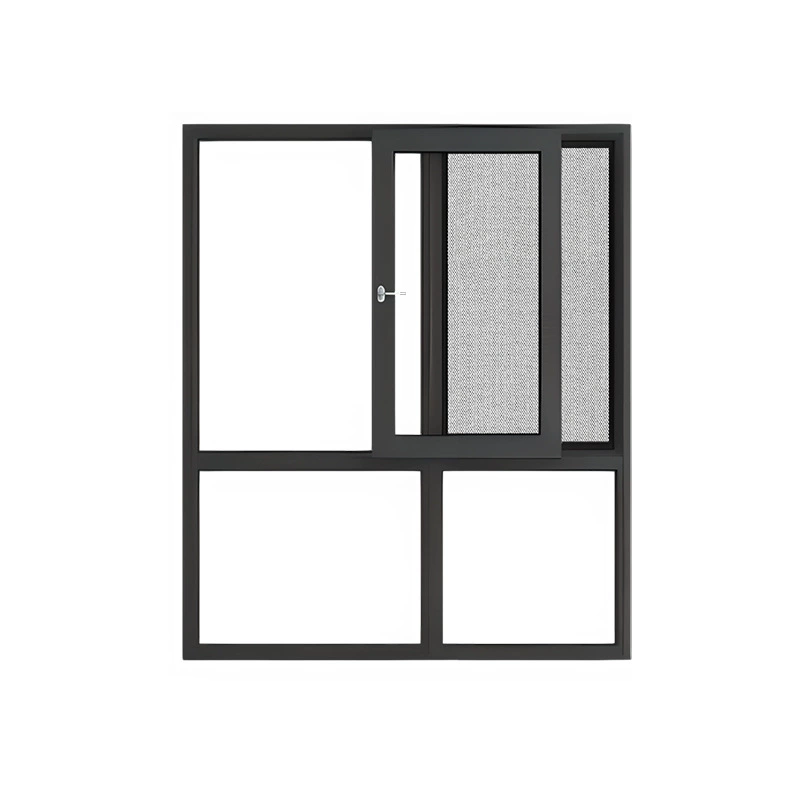

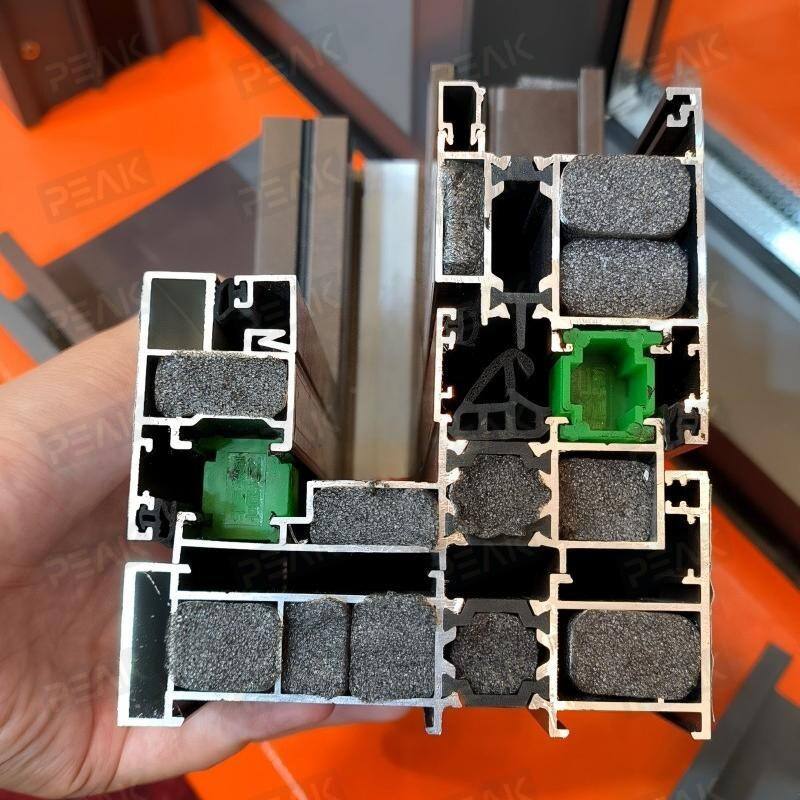

Shamolga ham, namlikka ham chidamli issiqlik uzilishli aluminiy eshiklar va derazalar ishlab chiquvchi zamonaviy arxitektura sohasidagi eng yuqori texnologiyani ifodalaydi va ilg'or muhandislik bilan amaliy funksionallikni birlashtiradi. Ushbu ixtisoslashtirilgan ishlab chiquvchilar zamonaviy qurilishdagi asosiy muammolarni hal etuvchi — energiya samaradorligi, ob-havo ta'siriga chidamlilik va konstruktivdurabilnostlarga ega bo'lgan yuqori samarali binolar komponentlarini yaratishga e'tibor qaratadi. Issiqlik uzilishli texnologiya ularning ishlab chiqarish jarayonining asosini tashkil etadi hamda ichki va tashqi aluminiy qismlar orasiga issiqlik o'tkazmaydigan materiallarni kiritish orqali issiqlik uzatilishini va kondensat hosil bo'lishini oldini oladi. Bu yangi yondashuv shamolga ham, namlikka ham chidamli issiqlik uzilishli aluminiy eshiklar va derazalar ishlab chiquvchisiga ichki haroratni qulay saqlab turish hamda energiya iste'molini kamaytirish imkonini beradigan mahsulotlarni yetkazib berishga yordam beradi. Shamolga chidamli xususiyatlar germetik tizimlarning aniq muhandislik yechimlari, ko'p nuqtali qulflash mexanizmlari hamda ekstremal ob-havo sharoitiga chidamli barqaror ramka konstruksiyasi orqali erishiladi. Suvdan himoya xususiyatlari orqali suvni ichki fazodan uzoqlashtiruvchi ilg'or drenaj tizimlari, ob-havoga chidamli germetik materiallar texnologiyasi hamda maxsus sochiq konfiguratsiyalari amalga oshiriladi. Zamonaviy shamolga ham, namlikka ham chidamli issiqlik uzilishli aluminiy eshiklar va derazalar ishlab chiquvchilari sifatni doimiy nazorat qilish, aniq o'lchovlarni ta'minlash maqsadida hisoblash ushbu dasturlaridan foydalangan holda avtomatlashtirilgan ishlab chiqarish uskunalardan foydalanadi. Ularning qo'llanilishi turar joy, tijorat hamda sanoat sohalarini qamrab oladi hamda ko'p qavatli binolar, lyuks uy-joylar, sog'liqni saqlash muassasalari, ta'lim muassasalari hamda mehmonxonalarda foydalaniladi. Texnik xususiyatlar korroziyaga chidamli bo'yalgan pokrishlarni, yaxshiroq izolyatsiya uchun ko'p xonaligina profillarni hamda ikki va uch qavatli oynalar jumladan, turli oynalash variantlari bilan mos keluvchanlikni o'z ichiga oladi. Yetakchi shamolga ham, namlikka ham chidamli issiqlik uzilishli aluminiy eshiklar va derazalar ishlab chiquvchilari tomonidan amalga oshiriladigan sifat nazorati choralariga havo singishiga, suv o'tishiga, strukturaviy ishlashga hamda issiqlik samaradorligiga qat'iy sinov protokollari kiradi hamda xalqaro qurilish qoidalariga hamda energiya standartlariga rioya etilishini ta'minlaydi.