Presisie Vervaardiging en Kwaliteitsversekering Uitnemendheid

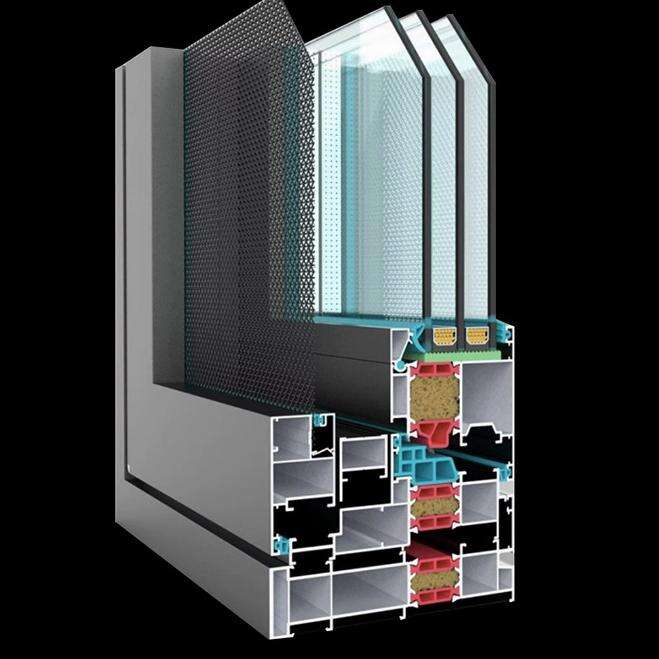

Die kantelglijdende aluminium deure en vensters met termiese breekfabrieke toon ongeëwenaarde toewyding aan presisie vervaardiging en omvattende gehalteversekeringsprotokolle wat nuwe industrienorme vestig vir uitstekendheid in venster- en deurprodukte. Hierdie gesofistikeerde fasiliteite maak gebruik van rekenaarbeheerde vervaardigingsapparatuur wat toleransies handhaaf wat in breuke van millimeter gemeet word, wat sodoende konsekwente pasmaat, afwerking en prestasie verseker oor alle produksieruns heen. Die gehaltebestuurstelsels wat deur die kantelglijdende aluminium deure en vensters met termiese breekfabrieke toegepas word, sluit elke aspek van die vervaardigingsproses in, vanaf grondstofinspeksie tot finale produktoetsing en verpakking. Gevorderde metingstelsels hou voortdurend kritieke dimensies, posisie van die termiese breek en samestellingsintegriteit dop, en merk outomaties enige afwykings van gevestigde spesifikasies op vir onmiddellike regstelling. Hierdie noukeurige benadering tot gehaltebeheer elimineer defektiewe produkte nog voor dit klante bereik, verminder installasievertragings en verseker projeksukses. Die fabriek se toetslaboratoriums voer omvattende prestasie-evalueringe uit, insluitend strukturele belastingstoetsing, luginfiltrasie-meting, waterdeurdringingsweerstand en termiese siklusassessering wat dekades se werklike blootstellingstoestande simuleer. Hierdie streng toetsprotokolle bevestig dat produkte konsekwent voldoen aan of selfs die gepubliseerde prestasiespesifikasies oortref, wat klante gerusstelling bied ten opsigte van hul beleggingsbesluite. Die kantelglijdende aluminium deure en vensters met termiese breekfabrieke handhaaf gedetailleerde dokumentasie van alle gehaltebeheeraktiwiteite, en skep spoorbaarheidstelsels wat garantiënkels ondersteun en voortgesette verbeteringsinisiatiewe moontlik maak. Bevoegde tegnici ondergaan uitgebreide opleidingsprogramme wat konsekwente toepassing van gehaltestandaarde oor alle produksieskofte en vervaardigingslyne waarborg. Die fabriek se toewyding tot uitnemendheid strek tot verpakking- en versendingsprosedures, met die gebruik van beskermende materiale en hanteringsprotokolle wat produkgehalte tydens vervoer en berging behou. Statistiese prosesbeheermetodes stel dit in staat om potensiële gehaltekwessies vroegtydig te identifiseer, wat preventiewe aanpassings moontlik maak om konsekwente produksiekwaliteit te handhaaf terwyl afval en produksievertragings tot 'n minimum beperk word. Hierdie omvattende benadering tot gehalteversekering het die kantelglijdende aluminium deure en vensters met termiese breekfabrieke gevestig as 'n verkose leverancier vir veeleisende toepassings waar betroubare prestasie en langtermynduursaamheid noodsaaklike vereistes is.