Algemene aanpassing en ontwerksoupligheid

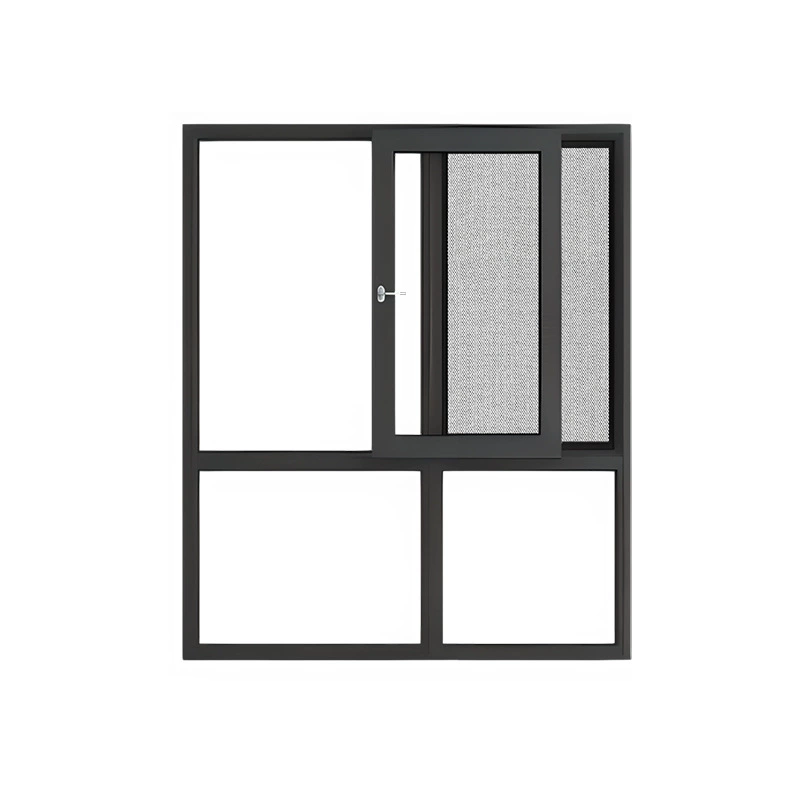

ʼN Gewilde vervaardiger van termiese-verbreek aluminium deure en vensters onderskei hulle deur omvattende aanpassingsopties te bied wat verskillende argitektoniese visies en prestasievereistes akkommodeer. Die aluminium-uittrekkingsproses maak byna onbeperkte profielvorme en konfigurasies moontlik, wat vervaardigers in staat stel om spesiale oplossings vir unieke projekbehoeftes te skep. Standaard kleuropties sluit gewoonlik tientalle poeierbedekte afwerwings, geanodiseerde behandelings en houtkorrelteksture in wat natuurlike materiale naboots terwyl aluminium se prestasievoordele behou word. Dientsye vir pasmaak-kleurmaching kan spesifieke argitektoniese palette of korporatiewe handelsmerkvereistes nabetref deur gebruik te maak van gevorderde kleurmetingstegnologie en gehaltebeheerprotokolle. Die strukturele vermoëns van termiese-verbreek aluminiumstelsels ondersteun grootskaalse glaswerktoepassings, met enkelpaneelafmetings wat groter as 3 meter by 4 meter kan wees terwyl strukturele integriteit en weerbestendigheid behou bly. Argitekte werk saam met die ingenieursafdelings van gewilde vervaardigers van termiese-verbreek aluminium deure en vensters tydens ontwikkeling, waar hulle strukturele berekeninge, termiese modellering en windlasontleding verskaf om stelselprestasie te optimeer. Geïntegreerde hardewarevermoëns sluit verskeie bedieningskonfigurasies in, soos klapvenster-, skuif-, kantel-en-draai-, vou- en hef-skuifmeganismes van verskeie internasionale leweransiers. Veiligheidsverbeterings kan tydens vervaardiging ingesluit word, insluitend meervoudige slotstelsels, gelamineerde glaswerk en verstewigde raamdele wat standaard veiligheidsgraderings oortref. Die glaswerkbuigsaamheid strek van standaard dubbelglas-eenhede tot gevorderde drievoudige glasstelsels met spesialisasiekorrelaas vir sonbeheer, privaatheid of dekoratiewe effekte. Akoestiese prestasie-aanpassing spreek spesifieke klankoordragvereistes aan deur keuse van glaswerk, raamafdigtingstelsels en spesiale pakkingontwerpe. Weerbestendigheid kan aangepas word aan streeksklimaatstoestande, met verbeterde dreinagestelsels vir hoë-neerslaggebiede, termiese uitsettingstoelaatbare ruimtes vir ekstreme temperatuurgebiede, en windweerstandgraderings vir kuslyn- of hoogbou-toepassings. Installasie-anpasbaarheid laat toe dat hierdie stelsels met verskillende muurkonstruksiemetodes geïntegreer kan word, insluitend steenwerk, staalraam, beton en gordynmuurtoepassings. Vervaardigingspresisie verseker bestendige gehalte oor alle aangepaste konfigurasies, met rekenaarbeheerde vervaardigingsprosesse wat noue toleransies handhaaf ongeag die ontwerpkompleksiteit. Gehoorwaarborgprotokolle bevestig dat aangepaste stelsels al hul prestasiessertifikasies en garantiadekking behou wat gelykstaand is aan standaardprodukte.