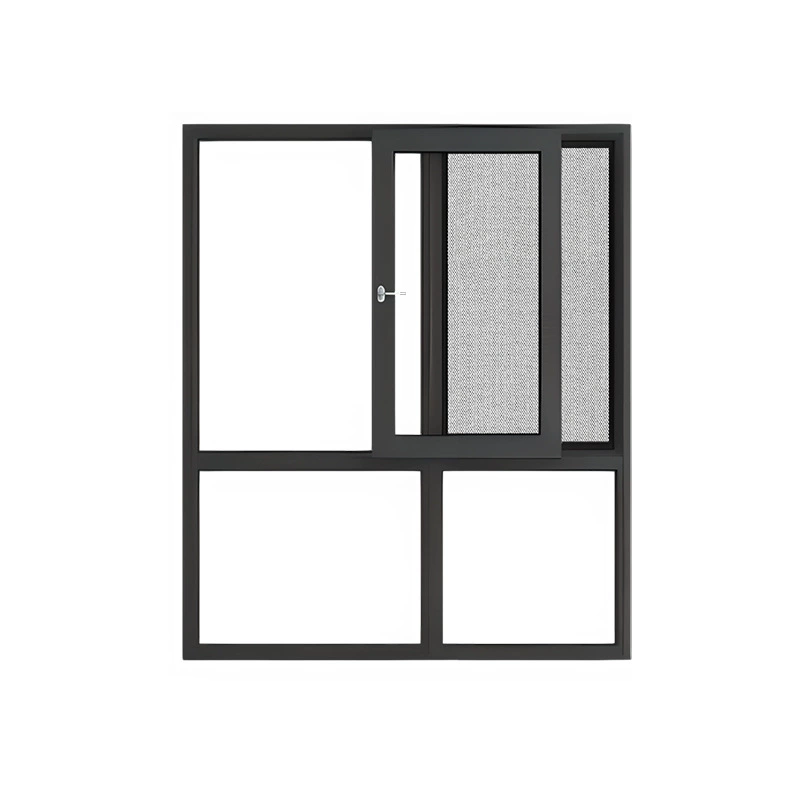

Versatile Design Options and Aesthetic Excellence

Quality energy efficient thermal break aluminum doors and windows offer unlimited design flexibility that empowers architects and designers to create stunning facades while meeting the most demanding performance requirements. The extensive profile libraries include options for casement, sliding, tilt-and-turn, folding, and pivot configurations that accommodate diverse architectural styles from contemporary minimalist designs to traditional classical applications. Custom fabrication capabilities enable the creation of curved, angled, and complex geometric shapes that transform conventional rectangular openings into architectural focal points without compromising thermal performance or structural integrity. Quality energy efficient thermal break aluminum doors and windows support oversized glass panels that maximize natural light penetration while maintaining slim sight lines that preserve unobstructed views and create seamless connections between interior and exterior spaces. The color palette includes hundreds of standard powder coating options plus unlimited custom colors that can match any architectural specification, with dual-color options allowing different interior and exterior finishes on the same frame. Glazing options range from clear float glass to advanced selective coatings, decorative patterns, laminated security glass, and even integrated photovoltaic panels that transform windows into energy-generating building components. Hardware selections include contemporary stainless steel, classic bronze, modern black, and custom finishes that complement the overall aesthetic vision while providing smooth, reliable operation for decades. Quality energy efficient thermal break aluminum doors and windows accommodate integrated shading systems, automated operation, and smart building controls that enhance user comfort while optimizing energy performance throughout varying seasonal conditions. The manufacturing precision enables tight tolerances and consistent quality that ensures perfect fit and finish regardless of project scale, from single residential units to massive commercial curtain wall installations. Specialized glazing retention systems provide structural glazing capabilities that create uninterrupted glass surfaces for modern architectural expressions while maintaining superior thermal and structural performance. Quality energy efficient thermal break aluminum doors and windows integrate seamlessly with building automation systems, enabling remote monitoring and control of natural ventilation, security functions, and climate optimization strategies that enhance occupant comfort while minimizing energy consumption.