Modern construction projects increasingly favor aluminum doors and windows due to their exceptional performance characteristics and long-term value proposition. These architectural elements have revolutionized the building industry by offering superior durability, energy efficiency, and aesthetic versatility that traditional materials simply cannot match. Property owners, architects, and contractors recognize that investing in high-quality aluminum systems delivers measurable returns through reduced maintenance costs, enhanced security, and improved thermal performance.

Superior Durability and Longevity

Corrosion Resistance Properties

Aluminum naturally forms a protective oxide layer that shields the underlying metal from environmental damage. This inherent corrosion resistance makes aluminum doors and windows ideal for coastal environments, industrial areas, and regions with harsh weather conditions. Unlike steel or iron-based materials, aluminum maintains its structural integrity without rusting, even when exposed to moisture, salt air, or chemical pollutants.

The anodizing process further enhances this natural protection by creating an even thicker oxide layer that penetrates deep into the aluminum surface. This treatment significantly extends the lifespan of aluminum doors and windows, often providing decades of reliable service with minimal degradation. Professional installations in marine environments have demonstrated exceptional performance lasting over 25 years without replacement.

Structural Strength and Stability

Modern aluminum alloys used in door and window manufacturing offer impressive strength-to-weight ratios that surpass many traditional materials. The lightweight nature of aluminum allows for larger glass panels and more expansive openings while maintaining structural stability. Engineering advances have produced aluminum profiles that can support substantial loads without warping, sagging, or developing operational issues over time.

Thermal expansion and contraction characteristics of aluminum are predictable and manageable through proper engineering design. Quality manufacturers incorporate expansion joints and flexible sealing systems that accommodate dimensional changes without compromising performance. This engineering approach ensures that aluminum doors and windows maintain proper alignment and sealing effectiveness throughout their service life.

Energy Efficiency and Thermal Performance

Advanced Insulation Technologies

Contemporary aluminum doors and windows incorporate sophisticated thermal break technologies that dramatically improve energy efficiency. Polyamide strips or similar insulating materials create barriers between interior and exterior aluminum sections, preventing thermal bridging that traditionally compromised aluminum's insulation performance. These thermal breaks can reduce heat transfer by up to 70 percent compared to non-thermally broken systems.

Multi-chamber designs within aluminum profiles create additional insulation zones that trap air and reduce thermal conductivity. When combined with high-performance glazing systems, modern aluminum doors and windows can achieve U-values comparable to or better than premium wood or vinyl alternatives. This thermal efficiency translates directly into reduced heating and cooling costs for building owners.

Air Sealing and Weather Protection

Precision manufacturing processes enable aluminum systems to achieve exceptional air sealing performance that minimizes unwanted infiltration and energy loss. Multiple weather sealing systems, including structural glazing and pressure-equalized designs, create barriers against wind-driven rain, dust, and air leakage. These sealing technologies maintain their effectiveness over decades, unlike organic materials that may deteriorate with UV exposure or temperature cycling.

Advanced testing protocols verify that quality aluminum doors and windows meet or exceed stringent air infiltration standards established by industry organizations. Professional installation techniques ensure that these laboratory-tested performance levels translate into real-world energy savings and occupant comfort in completed buildings.

Design Flexibility and Aesthetic Appeal

Architectural Versatility

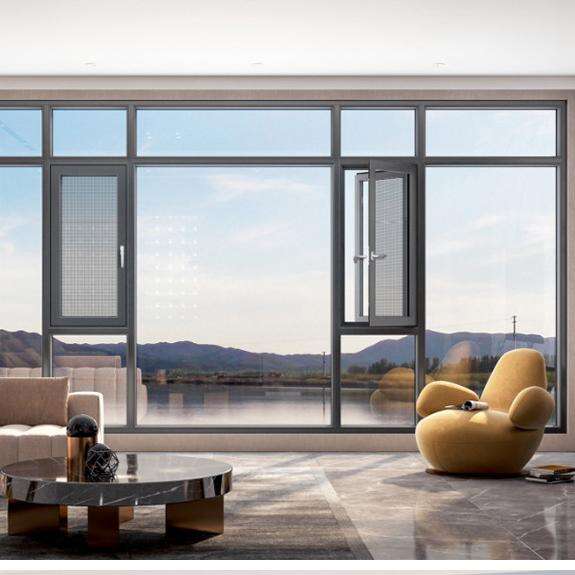

Aluminum's inherent strength allows for innovative architectural designs that would be impossible with other materials. Large expanses of glass, floor-to-ceiling windows, and dramatic curtain wall systems become feasible when supported by properly engineered aluminum framing. Minimal sightlines maximize natural light penetration while maintaining structural integrity and weather protection.

Custom fabrication capabilities enable architects to realize unique design visions through curved profiles, angled assemblies, and complex geometric configurations. Computer-controlled manufacturing processes ensure precise tolerances and consistent quality across custom projects, regardless of complexity or scale. This design freedom has made aluminum doors and windows the preferred choice for contemporary commercial and residential architecture.

Surface Finishing Options

Modern finishing technologies offer virtually unlimited color and texture possibilities for aluminum doors and windows. Powder coating systems provide durable, uniform finishes that resist fading, chipping, and environmental degradation. Anodizing processes create integral coloration that becomes part of the aluminum structure itself, ensuring lasting beauty without periodic refinishing.

Wood grain textures, metallic finishes, and even stone-like appearances can be applied to aluminum surfaces through advanced coating technologies. These decorative options allow aluminum systems to complement any architectural style, from traditional to ultra-modern, without sacrificing performance or durability characteristics.

Low Maintenance Requirements

Cleaning and Care Simplicity

Aluminum doors and windows require minimal ongoing maintenance compared to wood, steel, or composite alternatives. Regular cleaning with mild detergent and water removes accumulated dirt, pollutants, and biological growth without damaging the surface finish. The non-porous nature of aluminum prevents moisture absorption that could lead to rot, mold, or dimensional instability.

Hardware components used in quality aluminum systems are typically manufactured from stainless steel or other corrosion-resistant materials that maintain smooth operation with minimal lubrication. Periodic inspection and basic maintenance tasks can be performed by building maintenance staff without specialized training or expensive tools.

Long-Term Cost Savings

The extended service life of aluminum doors and windows significantly reduces lifecycle costs compared to materials requiring periodic replacement or major refurbishment. While initial investment costs may be higher than some alternatives, the total cost of ownership over 20-30 years typically favors aluminum systems due to minimal maintenance expenses and exceptional longevity.

Energy savings achieved through improved thermal performance compound these cost advantages by reducing utility expenses throughout the building's operational life. Many commercial and institutional projects have documented substantial returns on investment when upgrading from older window systems to modern aluminum alternatives.

Security and Safety Features

Intrusion Resistance

Aluminum doors and windows can be engineered to meet demanding security requirements without compromising aesthetic appeal or operational convenience. Multi-point locking systems, reinforced profiles, and laminated security glazing create formidable barriers against forced entry attempts. The inherent strength of aluminum framing provides excellent anchor points for advanced locking mechanisms.

Impact-resistant designs protect against both intentional intrusion and accidental damage from severe weather events. Hurricane-rated aluminum systems have demonstrated their ability to withstand extreme wind loads and debris impact while maintaining building envelope integrity.

Fire Safety Performance

Aluminum's non-combustible nature contributes positively to building fire safety strategies. Unlike vinyl or wood systems, aluminum doors and windows will not ignite or contribute fuel to building fires. This characteristic becomes particularly important in high-rise construction, industrial facilities, and other applications where fire resistance is critical.

Specialized fire-rated aluminum systems incorporate intumescent seals and other technologies that maintain compartmentalization during fire events. These systems can achieve substantial fire resistance ratings while preserving the aesthetic and operational benefits of standard aluminum construction.

Environmental Sustainability

Recyclability and Resource Conservation

Aluminum represents one of the most environmentally sustainable materials available for construction applications. The metal can be recycled indefinitely without degradation of its fundamental properties, and recycled aluminum requires only five percent of the energy needed to produce primary aluminum from ore. This exceptional recyclability makes aluminum doors and windows an environmentally responsible choice that supports circular economy principles.

End-of-life aluminum systems retain significant material value that encourages proper recycling rather than disposal in landfills. The established aluminum recycling infrastructure ensures that demolition and renovation projects can efficiently recover and reprocess aluminum components for use in new products.

Manufacturing Efficiency

Modern aluminum extrusion and fabrication processes operate with high energy efficiency and minimal waste generation. Computer-controlled manufacturing systems optimize material utilization and reduce scrap production. Many aluminum manufacturers have implemented comprehensive sustainability programs that address energy consumption, emissions reduction, and responsible sourcing practices.

Transportation efficiency benefits from aluminum's lightweight characteristics, reducing fuel consumption and emissions associated with delivery to construction sites. Local and regional manufacturing capabilities further minimize transportation impacts while supporting local economies.

FAQ

How long do aluminum doors and windows typically last

Quality aluminum doors and windows can provide reliable service for 25-30 years or more with proper installation and minimal maintenance. The corrosion-resistant properties of aluminum, combined with durable surface finishes, ensure long-term performance that often exceeds the service life of other window materials. Many commercial installations from the 1980s and 1990s continue operating effectively today with only routine maintenance.

Are aluminum doors and windows energy efficient

Modern aluminum doors and windows with thermal break technology achieve excellent energy efficiency ratings that rival or exceed other premium materials. The key is selecting systems with proper thermal barriers and high-performance glazing packages. U-values of 0.30 or lower are readily achievable with contemporary aluminum systems, providing substantial energy savings compared to older single-pane or non-thermally broken installations.

Do aluminum doors and windows require special maintenance

Aluminum doors and windows require less maintenance than most alternative materials. Regular cleaning with mild soap and water, periodic lubrication of moving parts, and inspection of weather seals represent the primary maintenance requirements. Unlike wood systems, aluminum never requires painting, staining, or treatment for rot prevention. The durable nature of aluminum finishes eliminates most periodic refinishing costs.

Can aluminum doors and windows be customized for specific architectural requirements

Aluminum systems offer exceptional customization capabilities through extrusion manufacturing processes that can create virtually any profile configuration. Custom colors, finishes, hardware options, and glazing packages allow architects to specify aluminum doors and windows that perfectly complement their design vision. Most manufacturers can accommodate special sizes, shapes, and performance requirements through their custom fabrication capabilities.