Comprehensive Design Flexibility and Aesthetic Appeal

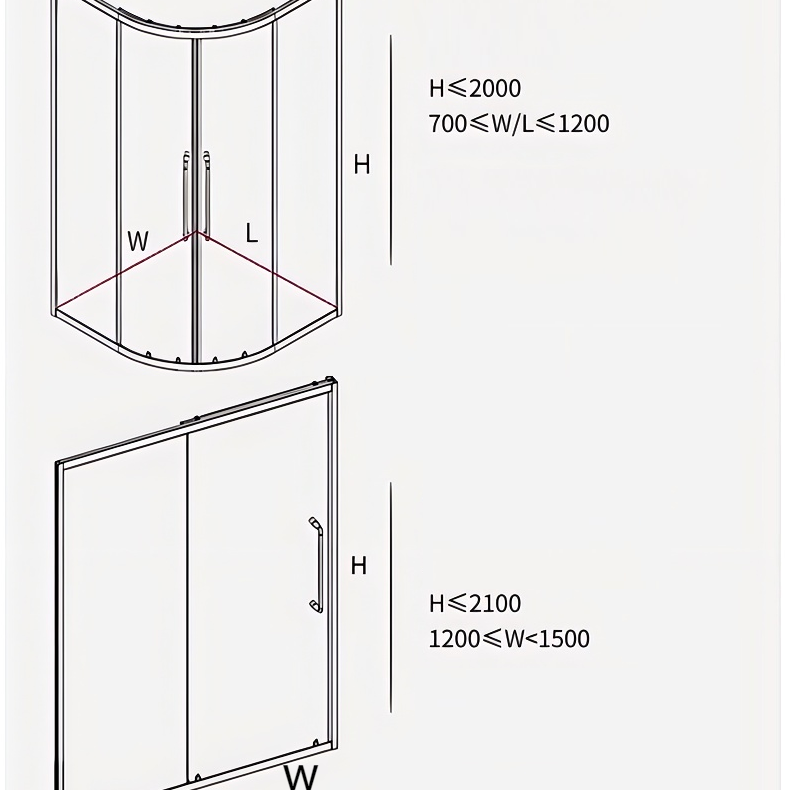

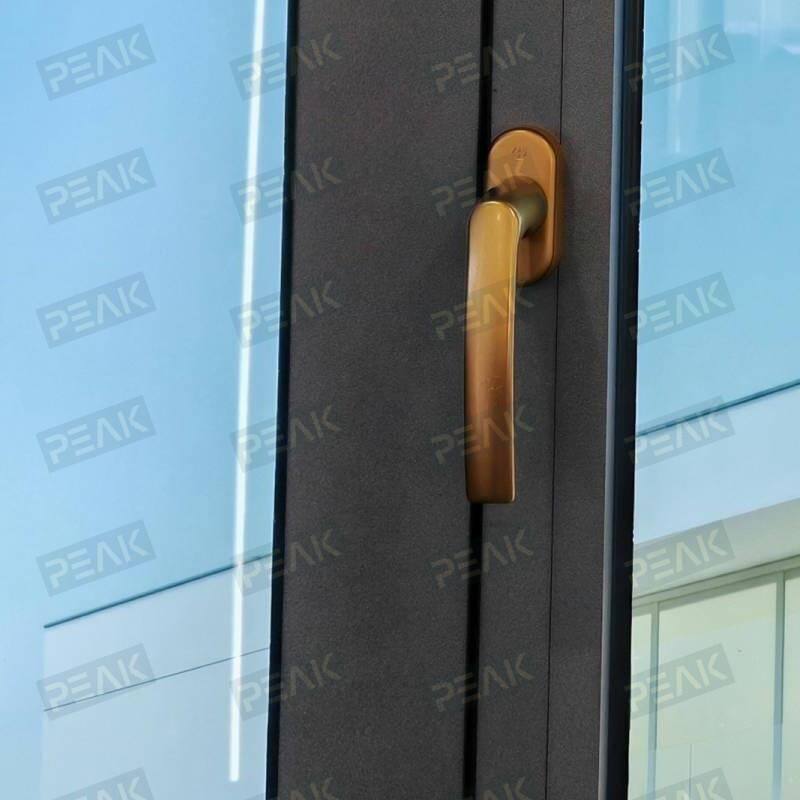

The thermal break aluminum doors and windows price provides access to unparalleled design flexibility that accommodates diverse architectural requirements while maintaining consistent performance standards. Modern thermal break systems offer extensive profile configurations ranging from narrow sightlines for contemporary aesthetics to traditional proportions for historic renovation projects. Color customization options include powder coating, anodizing, and specialized finishes that replicate wood grains, stone textures, or metallic effects, enabling seamless integration with any architectural style. The thermal break aluminum doors and windows price encompasses complex glazing configurations including double glazing, triple glazing, and specialized performance glass options such as low-emissivity coatings, laminated security glass, and decorative patterns. Operating hardware selections range from traditional mechanisms to contemporary multi-point locking systems, concealed hinges, and automated operators for commercial applications. The thermal break aluminum doors and windows price includes engineering support for custom applications such as curtain wall integration, structural glazing, and specialty shapes including arches, triangles, and complex geometric configurations. Large span capabilities enable dramatic architectural features such as floor-to-ceiling installations, corner windows, and uninterrupted sight lines that maximize natural light and views. The thermal break aluminum doors and windows price reflects sophisticated manufacturing capabilities that accommodate tight tolerances and precise fitment requirements essential for high-end construction projects. Surface preparation and finishing options ensure compatibility with diverse construction materials and installation methods, from traditional frame-in-frame applications to contemporary structural attachment systems. Quality control standards throughout manufacturing ensure consistent appearance and performance across large commercial projects or residential developments. The thermal break aluminum doors and windows price investment provides access to comprehensive technical support including structural calculations, thermal modeling, and installation guidance that ensures optimal performance and appearance throughout the building's service life.