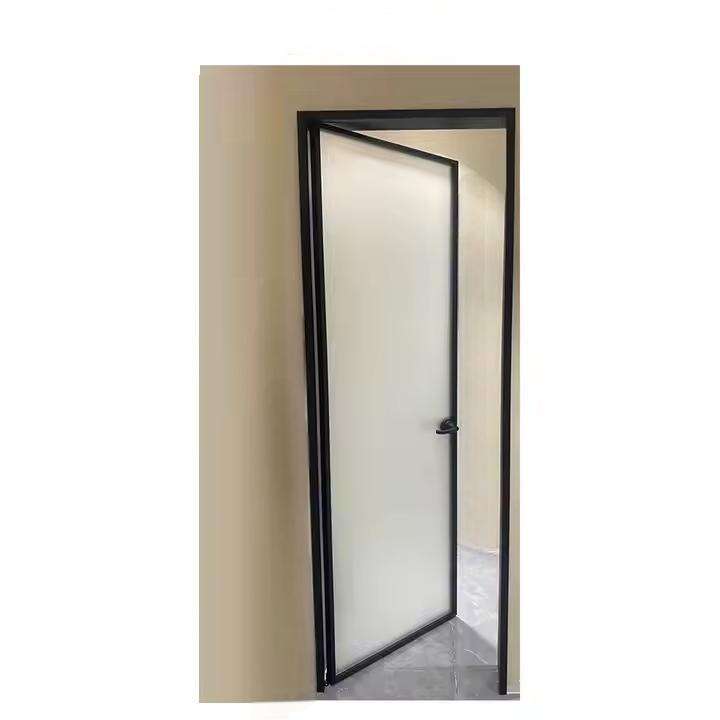

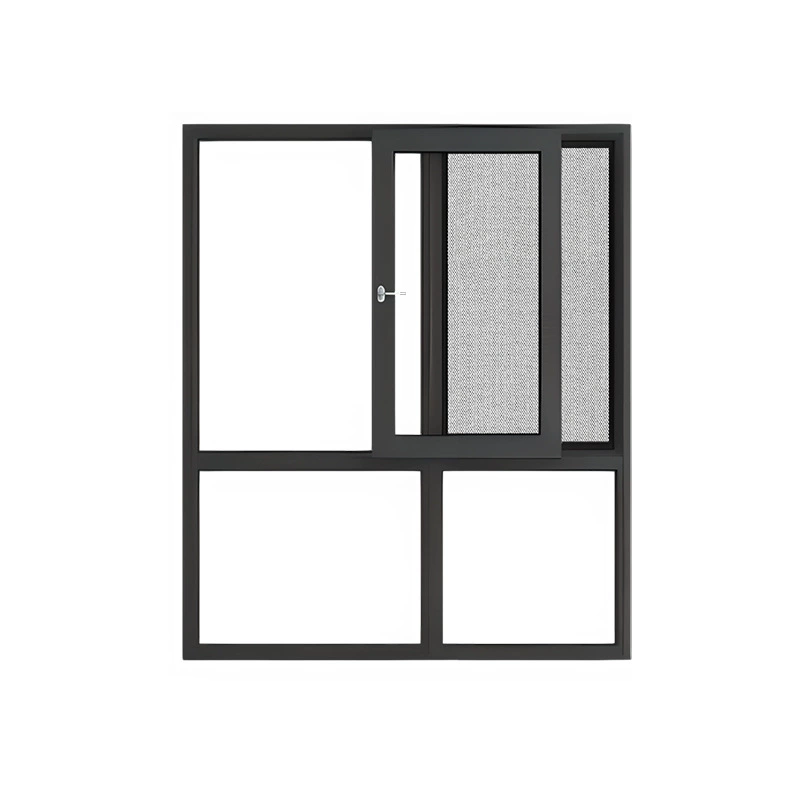

windproof & waterproof thermal break aluminum doors and windows manufacturer

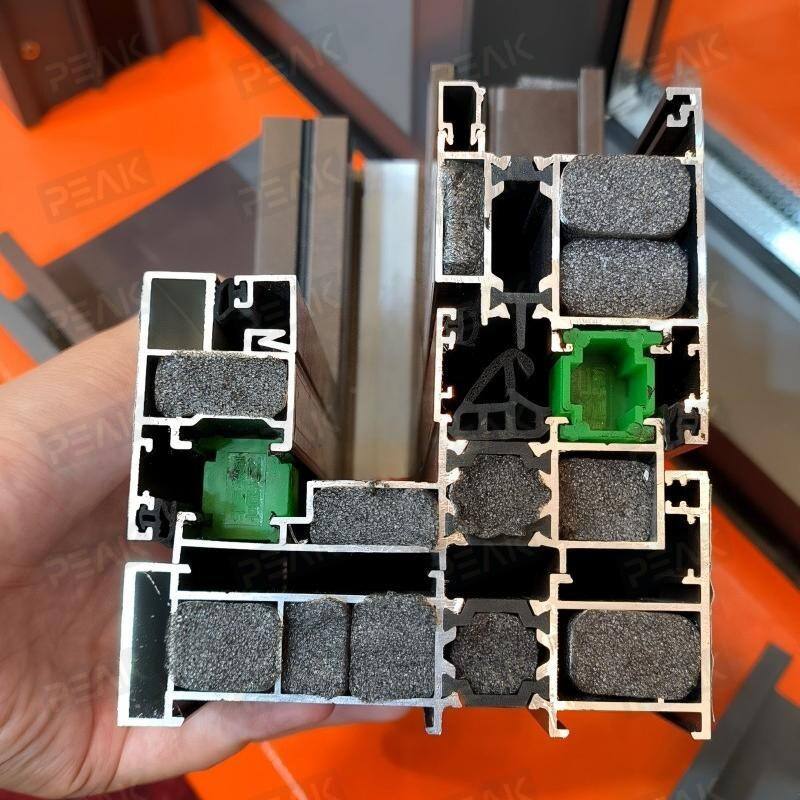

A windproof & waterproof thermal break aluminum doors and windows manufacturer represents the pinnacle of modern architectural fenestration technology, combining advanced engineering with practical functionality. These specialized manufacturers focus on creating high-performance building components that address critical concerns in contemporary construction, including energy efficiency, weather resistance, and structural durability. The thermal break technology serves as the cornerstone of their manufacturing process, incorporating insulating materials between inner and outer aluminum sections to prevent heat transfer and condensation formation. This innovative approach allows windproof & waterproof thermal break aluminum doors and windows manufacturer to deliver products that maintain comfortable indoor temperatures while reducing energy consumption. The windproof capabilities are achieved through precision engineering of sealing systems, multi-point locking mechanisms, and robust frame construction that withstands extreme weather conditions. Waterproof features include advanced drainage systems, weatherstripping technology, and specially designed sill configurations that redirect water away from interior spaces. Modern windproof & waterproof thermal break aluminum doors and windows manufacturer utilize computer-aided design software and automated production equipment to ensure consistent quality and precise tolerances. Their applications span residential, commercial, and industrial sectors, serving high-rise buildings, luxury homes, healthcare facilities, educational institutions, and hospitality venues. The technological features encompass advanced powder coating finishes for corrosion resistance, multi-chambered profiles for enhanced insulation, and compatibility with various glazing options including double and triple-pane configurations. Quality control measures implemented by leading windproof & waterproof thermal break aluminum doors and windows manufacturer include rigorous testing protocols for air infiltration, water penetration, structural performance, and thermal efficiency, ensuring compliance with international building codes and energy standards.