Exceptional Structural Durability and Low-Maintenance Performance

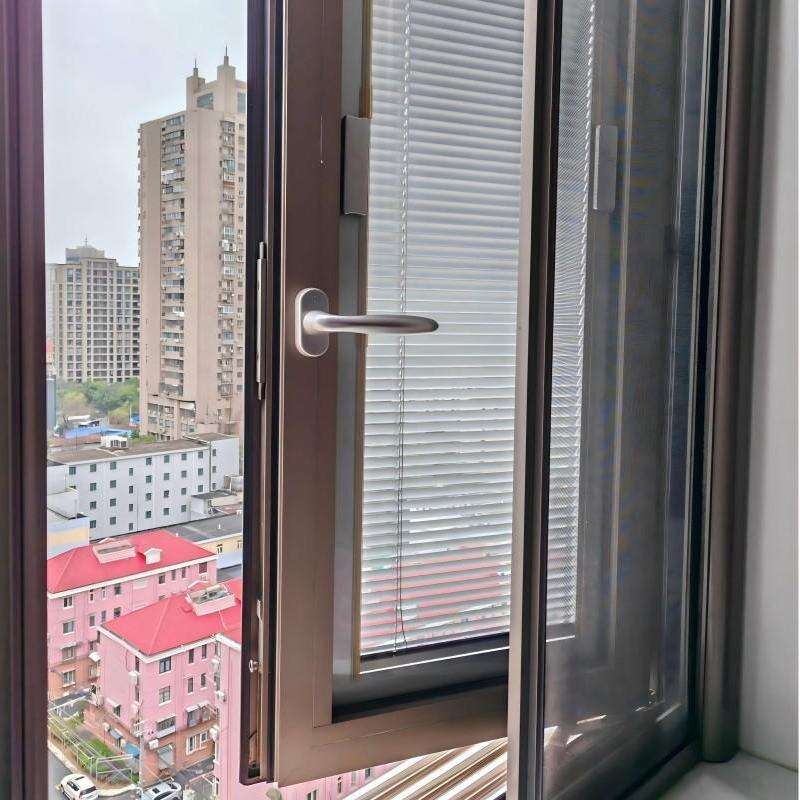

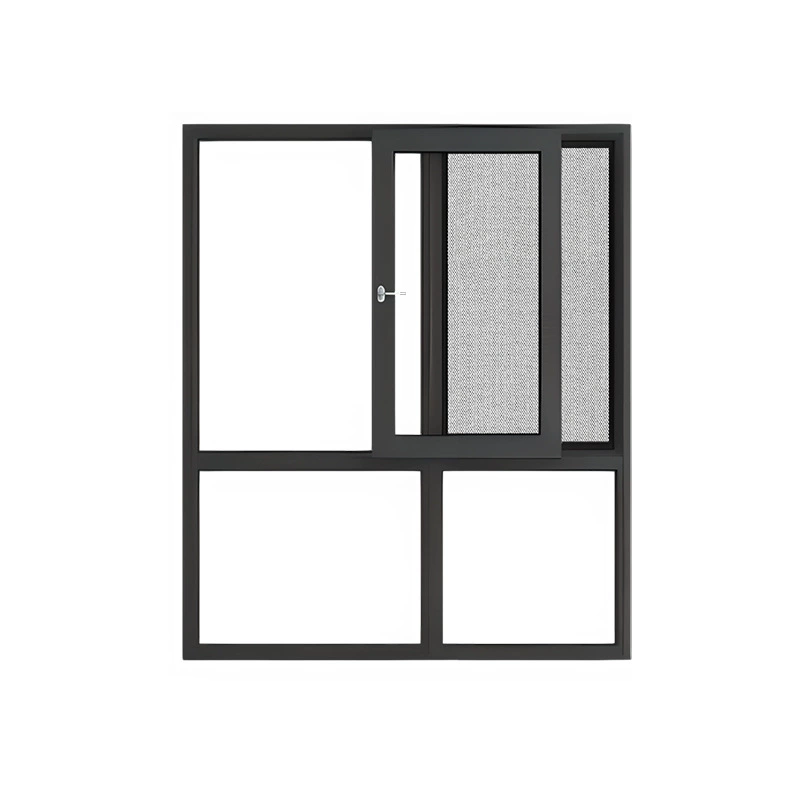

The exceptional structural durability engineered into the best windproof & waterproof thermal break aluminum doors and windows establishes these systems as long-term architectural investments that deliver consistent performance across decades of service. The aluminum alloy composition utilizes high-strength materials specifically formulated to resist corrosion, fatigue, and structural deformation under varied loading conditions. Advanced extrusion processes create frame profiles with optimized wall thicknesses and internal reinforcement geometries that maximize strength-to-weight ratios while accommodating thermal break integration. The structural design incorporates comprehensive load distribution systems that effectively transfer wind loads, seismic forces, and operational stresses throughout the frame assembly without compromising seal integrity or operational smoothness. Finite element analysis guides the development of connection details and reinforcement strategies, ensuring structural adequacy under extreme weather events and long-term loading scenarios. Surface treatment processes, including powder coating and anodizing options, provide protective barriers that prevent oxidation and maintain aesthetic appearance despite exposure to harsh environmental conditions. The powder coating systems utilize electrostatically applied polymer finishes that cure to form durable, chip-resistant surfaces available in extensive color ranges. Anodized finishes create integral oxide layers that become part of the aluminum substrate, providing permanent protection that cannot chip or peel away from the base material. These best windproof & waterproof thermal break aluminum doors and windows require minimal maintenance compared to alternative materials, typically needing only periodic cleaning and basic hardware lubrication to maintain optimal performance. The aluminum construction eliminates concerns about rot, warping, insect damage, or painting requirements associated with traditional materials. Hardware components undergo extensive testing for durability and smooth operation, with multi-point locking systems rated for hundreds of thousands of operational cycles. Quality assurance protocols include accelerated aging tests that simulate decades of weathering in compressed timeframes, validating long-term performance predictions. The modular construction approach facilitates component replacement if needed, extending overall system lifespan and supporting sustainable building practices through reduced waste generation and resource consumption over the building lifecycle.