Modern construction and renovation projects increasingly prioritize energy efficiency, sustainability, and long-term performance. Among the critical components that determine a building's thermal performance and overall aesthetic appeal are the window and door systems. High-quality aluminum doors and windows have emerged as the preferred choice for architects, contractors, and homeowners seeking durable, energy-efficient solutions that combine functionality with contemporary design. These advanced fenestration systems offer superior thermal insulation, weather resistance, and structural integrity while maintaining sleek profiles that complement modern architectural styles.

The evolution of aluminum fenestration technology has revolutionized how we approach building envelope design. Today's systems incorporate advanced thermal break technology, multi-chamber profiles, and high-performance glazing options that significantly reduce heat transfer while maximizing natural light penetration. These innovations address the growing demand for sustainable building solutions that meet stringent energy codes and environmental standards without compromising on durability or aesthetic appeal.

Thermal Performance and Energy Efficiency Benefits

Advanced Thermal Break Technology

Modern aluminum window and door systems utilize sophisticated thermal break technology to minimize heat conduction through the frame. These systems feature polyamide strips or foam-filled barriers that create an insulating zone between the interior and exterior aluminum profiles. This design effectively reduces thermal bridging, preventing heat loss during winter months and heat gain during summer periods, resulting in significant energy savings for building occupants.

The thermal break construction allows aluminum frames to achieve impressive U-values comparable to other high-performance materials while maintaining the inherent strength and durability advantages of aluminum. Advanced manufacturing processes ensure precise alignment and continuous thermal barriers throughout the frame system, eliminating potential weak points that could compromise thermal performance.

Multi-Chamber Profile Design

Contemporary aluminum doors and windows incorporate multi-chamber profile designs that create additional insulation zones within the frame structure. These chambers trap air, creating natural insulation barriers that enhance thermal performance beyond what single-chamber systems can achieve. The strategic placement of these chambers optimizes both structural strength and thermal efficiency.

Engineers design these multi-chamber systems to accommodate various glazing configurations and hardware requirements while maintaining optimal thermal performance. The chamber geometry is carefully calculated to prevent convection currents that could reduce insulation effectiveness, ensuring consistent performance across different operating conditions and climate zones.

Durability and Structural Advantages

Corrosion Resistance and Longevity

Aluminum naturally forms a protective oxide layer that provides excellent corrosion resistance, making it ideal for fenestration applications in diverse environmental conditions. This inherent property, combined with advanced surface treatments and anodizing processes, ensures that aluminum doors and windows maintain their structural integrity and aesthetic appearance for decades without significant maintenance requirements.

The corrosion resistance of aluminum is particularly valuable in coastal environments, industrial areas, and regions with extreme weather conditions where other materials might deteriorate rapidly. Proper surface finishing techniques further enhance this natural protection, creating barriers against salt spray, acid rain, and other environmental factors that can affect building components over time.

Structural Strength and Wind Resistance

The inherent strength-to-weight ratio of aluminum makes it exceptional for large-span openings and high-rise applications where structural performance is critical. Aluminum frames can support substantial glass loads while maintaining narrow sight lines that maximize daylight penetration and provide unobstructed views. This structural capability allows architects to design larger openings without compromising safety or performance.

Wind resistance testing demonstrates that properly engineered aluminum systems can withstand extreme weather events, including hurricanes and severe storms. The material's elastic properties allow frames to flex under load without permanent deformation, returning to their original shape once forces subside. This resilience is crucial for buildings in areas prone to severe weather conditions.

Design Flexibility and Aesthetic Options

Color and Finish Variations

Modern aluminum doors and windows offer extensive customization options through various finishing techniques including anodizing, powder coating, and wood-grain texturing. These processes allow manufacturers to create virtually any color or texture to match architectural requirements and design preferences. The durability of these finishes ensures long-lasting color retention and surface quality even under harsh environmental conditions.

Powder coating technology provides particularly robust finishes that resist fading, chalking, and surface degradation while offering exceptional color consistency across large installations. Wood-grain finishes allow aluminum systems to achieve the aesthetic appeal of natural wood while maintaining aluminum's performance advantages, making them ideal for projects where traditional materials are desired but not practical.

Profile Configurations and Hardware Integration

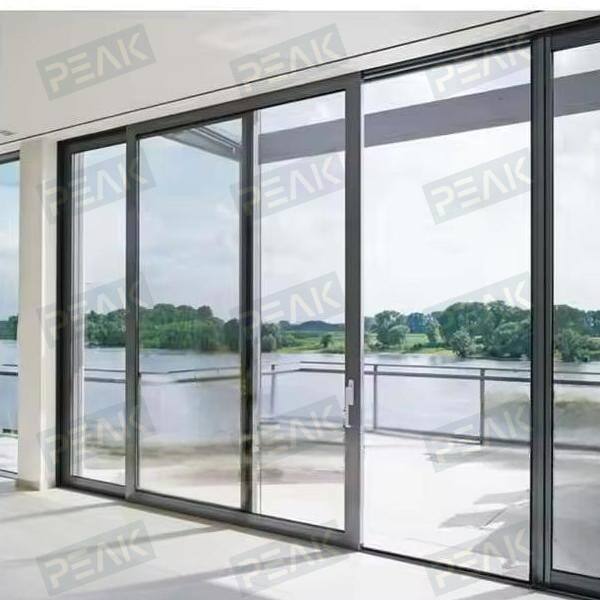

The versatility of aluminum extrusion processes enables manufacturers to create complex profile shapes that accommodate various operational requirements and aesthetic preferences. From traditional casement and awning configurations to contemporary tilt-and-turn and sliding systems, aluminum profiles can be engineered to support virtually any operational mechanism while maintaining optimal performance characteristics.

Hardware integration is seamlessly achieved through precision machining and engineering that ensures smooth operation, long-term durability, and enhanced security features. Modern aluminum systems can accommodate advanced locking mechanisms, automated opening systems, and smart building integration technologies that enhance user experience and building performance.

Installation and Maintenance Considerations

Professional Installation Requirements

Successful aluminum door and window installations require skilled professionals who understand the specific requirements of these systems. Proper installation techniques ensure optimal thermal performance, weather sealing, and structural integrity while preventing common issues such as thermal bridging, air infiltration, and water penetration. Professional installers utilize specialized tools and techniques developed specifically for aluminum fenestration systems.

Installation protocols must address structural connections, weatherproofing details, and thermal continuity requirements that are unique to aluminum systems. Proper flashing, sealant application, and insulation placement are critical for achieving designed performance levels and preventing moisture-related problems that can affect both the fenestration system and surrounding building components.

Long-Term Maintenance Benefits

One of the significant advantages of aluminum doors and windows is their minimal maintenance requirements compared to other materials. The natural corrosion resistance and durable surface finishes mean that routine maintenance typically involves only periodic cleaning and basic hardware lubrication. This low-maintenance characteristic translates to reduced lifecycle costs and improved long-term value for building owners.

When maintenance is required, aluminum systems are generally more straightforward to service than other materials. Hardware components can be easily accessed and replaced, seals and weatherstripping can be updated without frame modification, and surface refinishing can be accomplished without complete system replacement in most cases. This serviceability extends the useful life of installations and maintains performance over time.

Environmental Impact and Sustainability

Recyclability and Environmental Benefits

Aluminum is one of the most environmentally sustainable materials available for fenestration applications due to its infinite recyclability without loss of properties. At the end of their service life, aluminum doors and windows can be completely recycled into new products, significantly reducing environmental impact and supporting circular economy principles. This recyclability makes aluminum systems an excellent choice for green building projects and LEED certification pursuits.

The energy required to recycle aluminum is significantly lower than primary production, making recycled aluminum an environmentally responsible choice. Many manufacturers incorporate high percentages of recycled content in their products without compromising performance or quality, further enhancing the environmental benefits of choosing aluminum fenestration systems.

Energy Performance and Carbon Footprint

The superior thermal performance of modern aluminum doors and windows contributes significantly to building energy efficiency, reducing heating and cooling loads throughout the building's operational life. These energy savings translate to reduced carbon emissions and lower operational costs, making aluminum systems valuable contributors to sustainable building performance and climate change mitigation efforts.

Life cycle assessments demonstrate that the environmental benefits of aluminum fenestration systems, particularly their energy savings during the use phase, far outweigh any environmental impacts associated with production. When combined with the material's recyclability and durability, aluminum systems represent one of the most environmentally responsible choices for building envelope applications.

FAQ

How do aluminum doors and windows compare to vinyl in terms of energy efficiency

Modern aluminum doors and windows with thermal break technology can achieve energy efficiency levels comparable to or better than vinyl systems. While vinyl has natural insulating properties, aluminum systems compensate through advanced thermal break design and multi-chamber profiles. The key advantage of aluminum is its superior structural performance, allowing for larger glazing areas and thinner frames that maximize daylight while maintaining excellent thermal performance.

What maintenance is required for aluminum fenestration systems

Aluminum doors and windows require minimal maintenance compared to other materials. Routine care involves periodic cleaning with mild soap and water, annual inspection of weatherseals and hardware, and occasional lubrication of moving parts. The corrosion-resistant properties of aluminum and durable surface finishes mean that refinishing or major repairs are rarely necessary during the system's service life, making them extremely cost-effective over time.

Can aluminum systems be used in coastal environments

Aluminum doors and windows are excellent choices for coastal applications due to their superior corrosion resistance. The natural oxide layer that forms on aluminum provides protection against salt spray and marine environments. For enhanced performance in extreme coastal conditions, systems can be specified with marine-grade anodizing or specialized powder coatings that provide additional protection while maintaining aesthetic appeal and performance characteristics.

What glass options work best with aluminum frame systems

Aluminum frames can accommodate virtually any glazing configuration, from standard double glazing to advanced triple-glazed units with low-E coatings and inert gas fills. The structural strength of aluminum allows for larger glass panels and specialized glazing options such as impact-resistant glass, solar control coatings, and dynamic glass technologies. The frame design can be optimized to work with specific glazing systems to maximize overall window performance and meet project-specific requirements.