Modern construction and renovation projects increasingly favor aluminum doors and windows for their exceptional durability, energy efficiency, and sleek aesthetic appeal. These architectural elements have revolutionized the way homeowners and commercial property developers approach fenestration solutions, offering unparalleled versatility in design while maintaining superior performance standards. The growing demand for sustainable building materials has positioned aluminum doors and windows as a premium choice that combines functionality with environmental responsibility.

The aluminum fenestration industry has witnessed remarkable technological advancements over the past decade, transforming traditional window and door manufacturing processes. Contemporary aluminum doors and windows incorporate sophisticated thermal break technology, multi-point locking systems, and precision-engineered profiles that deliver exceptional performance across diverse climatic conditions. These innovations have elevated aluminum from a purely functional material to a design-forward solution that complements modern architectural trends while addressing stringent energy efficiency requirements.

Property owners today seek fenestration solutions that balance initial investment costs with long-term value creation. Aluminum doors and windows excel in this regard, offering remarkable longevity, minimal maintenance requirements, and excellent return on investment through enhanced property values and reduced energy consumption. The material's inherent resistance to corrosion, warping, and thermal expansion makes it particularly suitable for challenging environmental conditions where other materials might fail prematurely.

Superior Performance Characteristics

Thermal Efficiency and Energy Savings

Modern aluminum doors and windows incorporate advanced thermal break technology that significantly reduces heat transfer between interior and exterior environments. This engineering innovation involves inserting low-conductivity materials between aluminum frame components, creating an effective barrier against thermal bridging. The result is dramatically improved energy efficiency that can reduce heating and cooling costs by up to thirty percent compared to traditional single-glazed windows.

The thermal performance of contemporary aluminum fenestration systems often exceeds industry standards through the integration of multiple glazing layers, specialized gas fills, and low-emissivity coatings. These features work synergistically to create an insulation barrier that maintains comfortable interior temperatures while minimizing energy consumption. Advanced weather sealing systems further enhance thermal efficiency by eliminating air infiltration and moisture penetration.

Energy-efficient aluminum doors and windows contribute significantly to green building certifications and sustainability goals. The material's recyclability, combined with its energy-saving properties during operation, creates a comprehensive environmental benefit that appeals to environmentally conscious property owners and regulatory requirements for energy-efficient construction.

Structural Integrity and Durability

Aluminum's exceptional strength-to-weight ratio enables the creation of large-span openings without compromising structural integrity. This characteristic allows architects and designers to incorporate expansive glass areas that maximize natural light penetration while maintaining the structural requirements necessary for safe operation. The material's inherent stiffness prevents sagging and distortion that commonly affects other fenestration materials over time.

Corrosion resistance represents another critical advantage of aluminum doors and windows, particularly in coastal environments or areas with high humidity levels. The natural oxide layer that forms on aluminum surfaces provides inherent protection against atmospheric corrosion, while specialized anodizing and powder coating treatments offer additional protection and aesthetic customization options.

Wind load resistance capabilities of aluminum fenestration systems often exceed local building code requirements, providing additional safety margins during severe weather events. Advanced engineering calculations and testing protocols ensure that aluminum doors and windows maintain their operational characteristics even under extreme environmental stresses.

Design Flexibility and Aesthetic Options

Architectural Versatility

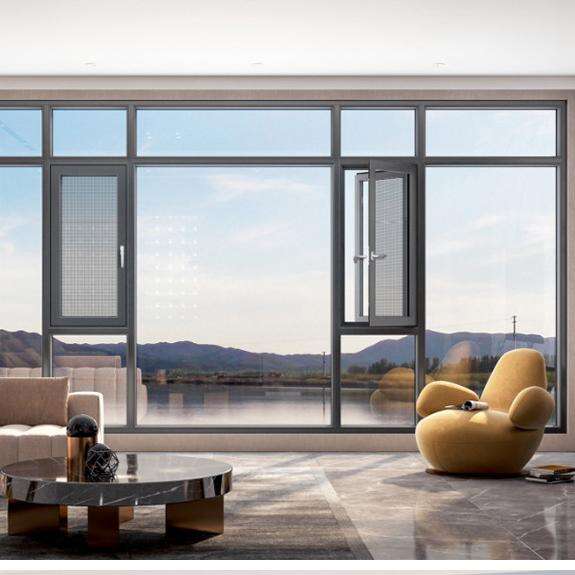

The inherent malleability of aluminum enables manufacturers to create complex profiles and shapes that accommodate diverse architectural styles and functional requirements. From traditional casement configurations to contemporary floor-to-ceiling installations, aluminum doors and windows adapt seamlessly to various design philosophies while maintaining consistent performance standards.

Slimline profiles characteristic of aluminum fenestration systems maximize glass area while minimizing frame visibility, creating clean aesthetic lines that complement modern architectural trends. This design approach allows for unobstructed views and enhanced natural light penetration, contributing to the overall ambiance and functionality of interior spaces.

Custom fabrication capabilities enable the creation of specialized shapes, including arched, circular, and angular configurations that would be challenging or impossible to achieve with other fenestration materials. This flexibility empowers architects to realize their design vision without compromising on performance or durability requirements.

Color and Finish Customization

Advanced surface treatment technologies offer virtually unlimited color and texture options for aluminum doors and windows. Powder coating processes provide durable finishes that resist fading, chalking, and environmental degradation while offering rich color depth and consistency across large installations. These finishes maintain their appearance for decades with minimal maintenance requirements.

Anodizing treatments create distinctive metallic finishes that enhance the natural properties of aluminum while providing additional corrosion protection. This process allows for a range of appearances from brushed and polished effects to specialized color variations that complement specific architectural themes.

Wood-grain finishes applied through advanced transfer technologies enable aluminum doors and windows to replicate the appearance of natural timber while retaining all the performance advantages of aluminum construction. This innovation satisfies aesthetic preferences for traditional materials while delivering contemporary functionality and maintenance benefits.

Installation and Maintenance Considerations

Professional Installation Requirements

Proper installation of aluminum doors and windows requires specialized knowledge of thermal expansion characteristics, structural load distribution, and weather sealing techniques. Professional installation ensures optimal performance, longevity, and compliance with manufacturer warranty requirements. Experienced installers understand the critical importance of precise measurements, appropriate fastening methods, and proper integration with building envelope systems.

Thermal expansion considerations necessitate specific installation techniques that accommodate dimensional changes throughout seasonal temperature variations. Professional installers incorporate expansion joints, flexible sealing materials, and appropriate fastening systems that maintain structural integrity while allowing for natural material movement.

Quality installation includes comprehensive weather sealing systems that prevent water infiltration, air leakage, and moisture problems. These systems require careful attention to detail and understanding of building science principles to ensure long-term performance and occupant comfort.

Long-term Maintenance Benefits

Aluminum doors and windows require minimal ongoing maintenance compared to alternative fenestration materials. Regular cleaning with mild detergents and periodic inspection of hardware components typically suffice to maintain optimal appearance and functionality throughout the product's service life. The absence of painting, staining, or refinishing requirements significantly reduces long-term ownership costs.

Hardware maintenance involves periodic lubrication of moving components and adjustment of locking mechanisms to ensure smooth operation. High-quality hardware systems incorporated in premium aluminum fenestration products often feature self-lubricating components and corrosion-resistant materials that extend service intervals and reduce maintenance requirements.

Preventive maintenance programs can identify potential issues before they compromise performance or appearance. Regular inspection of weather seals, drainage systems, and hardware operation ensures continued efficiency and prevents minor problems from developing into costly repairs.

Cost Analysis and Investment Value

Initial Investment Considerations

The initial cost of aluminum doors and windows reflects the premium materials, advanced manufacturing processes, and superior performance characteristics inherent in these products. While upfront costs may exceed some alternative materials, the total cost of ownership often favors aluminum due to reduced maintenance requirements, energy savings, and extended service life.

Pricing variables include frame complexity, glazing specifications, hardware quality, and finish options. Standard configurations typically offer the most cost-effective solutions, while custom shapes, specialized finishes, and advanced glazing systems command premium pricing that reflects their enhanced performance and aesthetic benefits.

Professional installation costs should be factored into overall project budgets, as proper installation directly impacts product performance and warranty coverage. Qualified installers may charge premium rates, but their expertise ensures optimal results and long-term satisfaction with the investment.

Return on Investment Analysis

Energy savings generated by high-performance aluminum doors and windows contribute significantly to return on investment calculations. Reduced heating and cooling costs compound over time, often offsetting the premium initial investment within several years of operation. These savings continue throughout the product's service life, creating substantial long-term value.

Property value enhancement represents another significant return on investment factor. Quality aluminum fenestration systems improve curb appeal, energy efficiency ratings, and overall property marketability. Real estate professionals consistently report that homes and commercial properties with premium window and door systems command higher sale prices and shorter market times.

Maintenance cost avoidance contributes to overall investment returns through elimination of periodic refinishing, replacement, and repair expenses associated with other fenestration materials. The durability and longevity of aluminum doors and windows translate into predictable ownership costs and reduced lifecycle expenses.

FAQ

How long do aluminum doors and windows typically last

Quality aluminum doors and windows typically provide service lives exceeding thirty years with proper installation and routine maintenance. The corrosion-resistant properties of aluminum, combined with durable finish systems and high-quality hardware, contribute to exceptional longevity that often exceeds the performance of alternative fenestration materials. Many manufacturers offer warranties ranging from ten to twenty years, reflecting confidence in product durability and performance.

Are aluminum doors and windows energy efficient

Modern aluminum doors and windows incorporate advanced thermal break technology, multi-pane glazing systems, and precision weather sealing that deliver excellent energy efficiency performance. These systems often exceed ENERGY STAR requirements and contribute to green building certifications. The thermal break technology effectively eliminates the thermal bridging that characterized older aluminum fenestration products, resulting in energy performance comparable to or exceeding other premium fenestration materials.

What maintenance is required for aluminum doors and windows

Aluminum doors and windows require minimal maintenance consisting primarily of regular cleaning with mild soap solutions and periodic hardware lubrication. The corrosion-resistant properties of aluminum eliminate the need for painting or refinishing, while quality powder coat finishes maintain their appearance for decades. Annual inspection of weather seals, drainage systems, and hardware operation helps ensure continued optimal performance and early identification of any service requirements.

Can aluminum doors and windows be customized for specific architectural requirements

Aluminum's excellent formability enables extensive customization options including custom shapes, sizes, colors, and hardware configurations. Manufacturers can create specialized profiles for unique architectural applications, while powder coating and anodizing processes offer virtually unlimited color and finish options. Custom glazing specifications, integrated blinds, and specialized hardware systems further expand the customization possibilities to meet specific performance and aesthetic requirements.