bestu hlutbrotna alúminiðurra og glugga frumvarpari

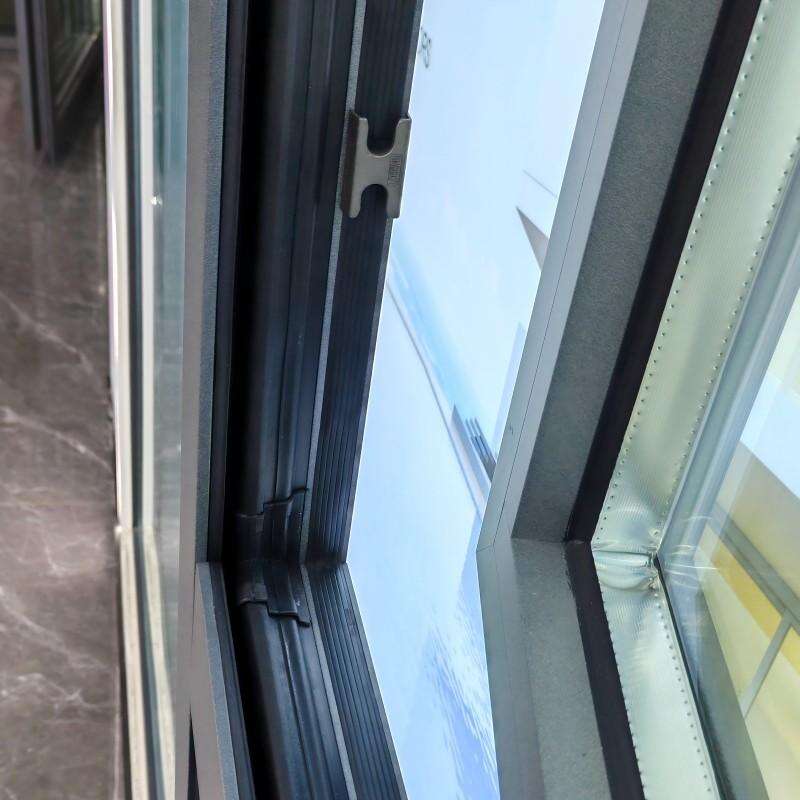

Besti framleiðandinn af hitaeftirlitjum úr glugga og hurðum í ál er táknið fyrir mótíðenda gluggatækni, sem sameinar áframhugsað verkfræði efna við nýjustu framleiðsluaðferðir til að veita framúrskarandi afköst. Þessir sérhæfðu framleiðendur beinlínis leita að að búa til orkuvinauðga vörur sem uppfylla núverandi kröfur bygginga, en samt halda á snyrtilegri útliti og gerðarstyrk. Hitaeftirlit er grunnsteinninn í þróun vöruhaldsins, þar sem polyamíd-belti eða önnur varmaeyðandi efni eru notuð til að hindra varmaverkan gegnum álramm. Þessi nýjungarsmiðja breytir hefðbundnum gluggum og hurðum úr ál í hárafköstum byggingareiningar sem minnka orkunotkun marktækt og bæta komfort innbyggjanda. Leiðtogar í þessum greini leggja mikla áherslu á rannsóknir og þróun til að endurskipta bæta á hitaeftirlitskerfnum sínum, svo bestu varmaleiðni og andvarnar á rosku séu tryggð. Framleiðsluaðferðin felur í sér nákvæma verkfræði, þar sem álprófíl eru smíðuð með sérstökum gröfum fyrir innsetningu hitaeftirlits. Nýjungartækni í útþvingun býr til flókin rúmfræðiform sem henta mörgum veðurþéttunarkerfjum, vélbúnaðarkerfjum og gluggagleraugustillingum án þess að missa á gerðarstyrk. Gæðastjórnun felur í sér strangar prófunaraðferðir sem meta varmaleiðni, loftlekaþol, vatnsþol og gerðarþol. Besti framleiðandinn af hitaeftirlitjum úr glugga og hurðum í ál býður oft upp á umfjöllunartaugavörur, svo sem rekkjaglugga, skjólaga kerfi, hall-kippa lögun, inngangshurðir, garðahurðir og fellugerðarkerfi. Þessar vörur eru notaðar í bæði íbúða-, iðnaðar- og stofnunarbyggingum, þar sem orkuvinauðgi, varanakennd og hönnunarfrelsi eru af mikilvægi. Framleiðslustöðvar eru oft búsettar með nýjasta búnaði, svo sem CNC-vélakerfum, sjálfvirkum skerivélakerfjum og nákvæmum samsetningarborðum sem tryggja samræmd gæði og víddanákvæmni. Samruni snjallra framleiðslutækni gerir fyrirtækjunum kleift að bjóða upp á sérsníðdar lausnir án þess að missa á keppnishæfum framleiðslutímum og kostnadarmynd.