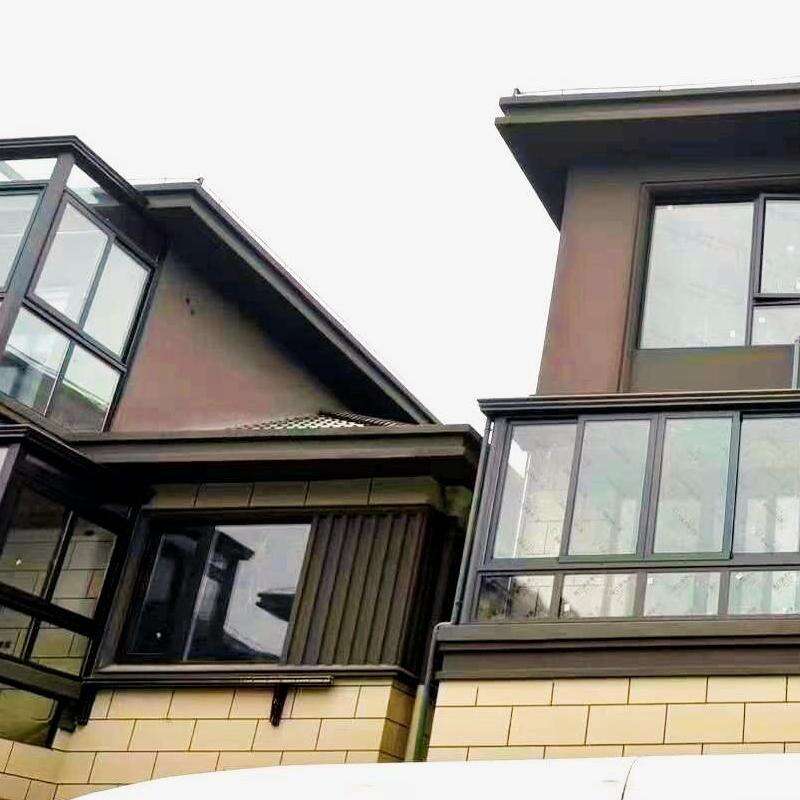

Praestans Structurae Durabilitas et Rara Materiae Perpetuatio ad Longum Tempus Valoris

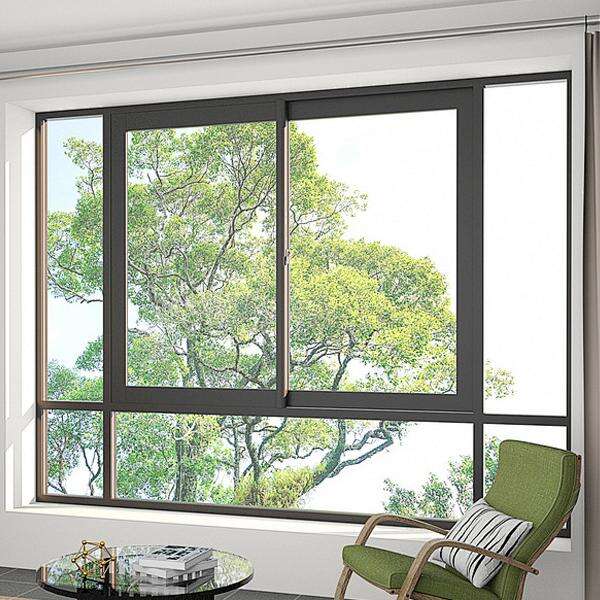

Praestans durabilitas structurae et exigua menda requisita valvis fenestrarumque alligatis vel labentibus ex alluminio cum ruptura thermica qualitatis oriuntur ex alligatio alluminii altiore arte facta et technologiis tractationis superficiei subtilibus, quae decennia performance credibilis in condicionibus environmentalibus difficilibus firmant. Structura alluminii alligationes altius resistens adhibet speciatim compositas ad applicationes architectonicas, praebens vim tensionalem superiorem, resistentiam corrosioni, et stabilitatem dimensionalem quae materiales aedificandi tradicionales superat. Haec alligationes processibus extrusionis praecisis percurrent, quae crassitudines parietum uniformes, geometrias structurales optimizatas, et figuras refortificationis integratas creant, quae onera efficaciter distribuunt per totam compositionem structurae. Proprietates innatae alluminii resistentiam naturalem corrosioni, non-combustibilitatem, et immunitatem a damno insectorum, putredine, ac deteriatione coniuncta humore includunt, quae saepissime lignum et materiales compositos afficit. Processus tractationis superficialis progressi sicut anodizatio, pulvis colorandus, et pelliculae protectivae speciales has proprietates naturales augent simulque optiones amplitudinis colorum texturarumque praebent. Processus anodizationis stratum oxidi durabile generat quod cum superficie alluminii fit integrum, protectionem perpetuam praebens adversus oxidationem, evanescendum, et usum. Applicationes pulveris colorandi finitiones polymeras electrostatice applicatas utuntur quae in strata superficiales valde durabilia coagulant, quae adversus frangendum, radebundum, et expositionem chemicam resistunt. Hae tractationes protectivae vultum suum et proprietates performance per decennia retinent cum requisitis mendi exiguis. Purgo cotidiana cum solutionibus aquae saponis communibus terram collectam et contaminatores ambientales aufert sine productis specialibus aut proceduris purgandi agressivis requiritis. Tolerantiae manufacturationis praecisionis in valvis fenestrarumque alligatis vel labentibus ex alluminio cum ruptura thermica qualitatis assecutae aptationem et functionem rectam confirmant quae quaestiones mendi vulgares ut haesitatio, effusio aeris, et praeputialitas usus ferramentorum eliminant. Componentes ferramentorum ferrum non-vulgibile, aurichalcum, et alia materiales corrosioni-resistentia utuntur quae operationem lepidam et figuras securitatis per periodos servitii longas retinent. Systemata signandi meteoris gypsam et signa altius perfomantiae incorporant quae flexibilitatem et efficacitatem signandi retinent licet cyclis thermalibus et expositioni UV. Haec combinatio materialium durabilium, tractationum protectorum, et ingeniariae praecisionis solutionem costarum ciclica-minimarum creat quae reditum praestantissimum in investitione praebet per expensas mendi reductas, vitae servitii prolongatae, et fiduciam in performance constantem quae valorem immobilis et satisfactionem incolarum servat.