Penyesuaian Penuh dan Fleksibiliti Reka Bentuk

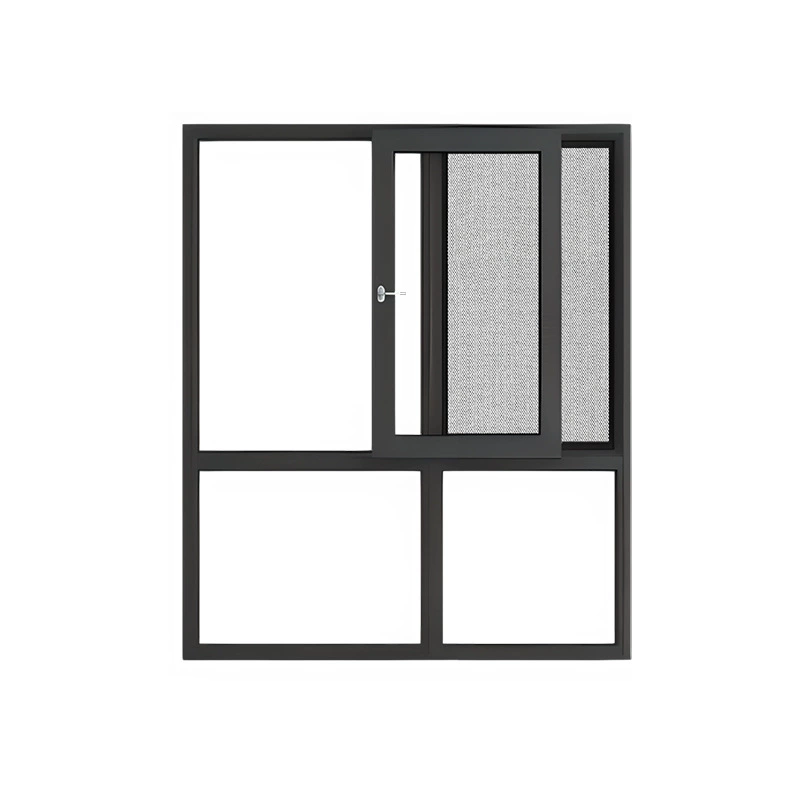

Seorang pengeluar pintu dan tingkap aluminium thermal break yang terkenal unggul dalam menyediakan pelbagai pilihan penyesuaian yang memenuhi pelbagai visi senibina dan keperluan prestasi. Proses pengeluran aluminium membolehkan bentuk dan konfigurasi profil yang hampir tidak terhad, membolehkan pengilang mencipta penyelesaian tersuai untuk menepati keperluan projek yang unik. Pilihan warna piawai biasanya merangkumi puluhan kemasan salutan serbuk, rawatan anod, dan tekstur urat kayu yang meniru bahan asli sambil mengekalkan kelebihan prestasi aluminium. Perkhidmatan padanan warna tersuai boleh menghasilkan palet senibina tertentu atau keperluan jenama korporat menggunakan teknologi pengukuran warna lanjutan dan protokol kawalan kualiti. Keupayaan struktur sistem aluminium thermal break menyokong aplikasi kaca berskala besar, dengan panel tunggal mencapai dimensi melebihi 3 meter kali 4 meter sambil mengekalkan integriti struktur dan prestasi cuaca. Jabatan kejuruteraan pengeluar pintu dan tingkap aluminium thermal break yang popular bekerjasama dengan arkitek semasa pembangunan reka bentuk, menyediakan pengiraan struktur, pemodelan haba, dan analisis beban angin untuk mengoptimumkan prestasi sistem. Keupayaan integrasi perkakasan merangkumi pelbagai konfigurasi operasi termasuk mekanisme tingkap buka sisi, gelangsar, condong-dan-pusing, lipat, serta gelongsor-angkat dari pelbagai pembekal antarabangsa. Penambahbaikan keselamatan boleh dimasukkan semasa proses pengilangan, termasuk sistem kunci pelbagai titik, kaca laminasi, dan anggota rangka diperkukuh yang melebihi penarafan keselamatan piawai. Kelenturan kaca merangkumi unit berganda piawai hingga sistem tiga lapis maju dengan salutan khas untuk kawalan solar, privasi, atau kesan hiasan. Penyesuaian prestasi akustik menangani keperluan transmisi bunyi tertentu melalui pemilihan kaca, sistem penyegelan rangka, dan rekabentuk getah khas. Prestasi terhadap cuaca boleh disesuaikan mengikut keadaan iklim kawasan setempat, dengan sistem saliran dipertingkatkan untuk kawasan berhujan lebat, pelarasan pengembangan haba untuk zon suhu ekstrem, dan penarafan rintangan angin untuk aplikasi pinggir pantai atau bangunan tinggi. Keupayaan pemasangan yang fleksibel membolehkan sistem ini diintegrasikan dengan pelbagai kaedah pembinaan dinding termasuk batu bata, rangka keluli, konkrit, dan aplikasi dinding tirai. Ketepatan pengilangan memastikan kualiti yang konsisten merentasi konfigurasi tersuai, dengan proses fabrikasi dikawal komputer mengekalkan had toleransi ketat tanpa mengira kerumitan rekabentuk. Protokol jaminan kualiti mengesahkan bahawa sistem tersuai mengekalkan semua pensijilan prestasi dan perlindungan waranti yang setara dengan produk piawai.