Hassas İmalat ve Kalite Kontrol Mükemmelliği

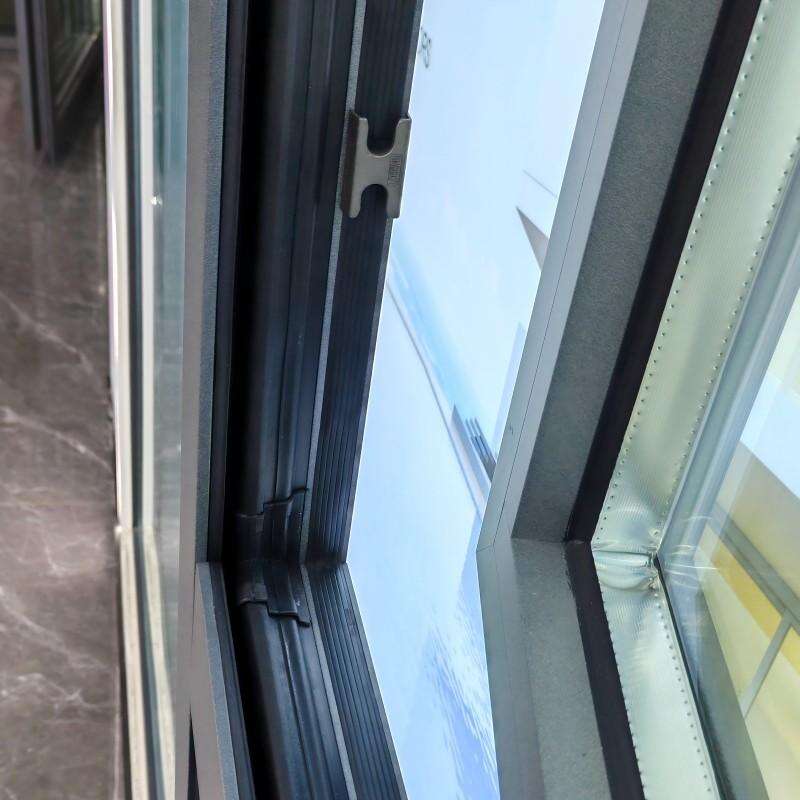

En iyi ısı köprüsüz alüminyum kapı ve pencere üreticisinin sergilediği üretim mükemmelliği, gelişmiş üretim metodolojilerini, son teknoloji ekipman kullanımını ve üstün ürün tutarlılığı ile performans güvenilirliğini garanti eden kapsamlı kalite güvence protokollerini kapsamaktadır. Son teknoloji üretim tesisleri, çok eksenli CNC merkezleri, otomatik profil kesme sistemleri ve milimetrenin ondalık kesirlerinde hassasiyetle çalışan delik delme ekipmanları gibi bilgisayar kontrollü makinelerle donatılmıştır. Bu yüksek düzeydeki hassasiyet, ürünün kullanım ömrü boyunca doğru ısı köprüsü montajı, hava sızdırmazlık işlevi ve donanım çalışması açısından kritik öneme sahiptir. Kalite kontrolü, alüminyum ekstrüzyonların üretim süreçlerine girmeden önce boyutsal doğrulama, alaşım kompozisyon analizi ve yüzey kalitesi değerlendirmesinden geçtiği hammaddenin girişinde yapılan muayeneyle başlar. İleri düzey üreticiler, termal performans odaları, yapısal yük test ekipmanları ve aşırı koşullar altında ürün performansını değerlendiren iklimlendirme simülasyon sistemleriyle donatılmış özel test laboratuvarlarını sürdürüyorlar. Her üretim partisi, termal iletkenlik değerleri, hava sızma direnci, su nüfuzu direnci ve yapısal dayanım özelliklerini doğrulayan sistematik örnek alma ve test prosedürlerinden geçirilir. Üretim personeli, montaj teknikleri, kalite standartları ve muayene prosedürleri konularında kapsamlı eğitimler alarak tüm üretim operasyonlarında tutarlı bir işçilik kalitesinin sağlanmasını garanti eder. Üretim verimliliğinin optimize edilmesini mümkün kılan yalın üretim prensipleri ve sürekli iyileştirme metodolojilerinin entegrasyonu, önde gelen üreticilerin olağanüstü kalite standartlarını korurken aynı zamanda verimliliği artırmalarına olanak tanır. İzlenebilirlik sistemleri, her ürünü ham maddenin kabulünden nihai muayeneye kadar takip ederek garanti taleplerini ve performans doğrulamayı destekleyen kapsamlı belgelendirme oluşturur. Gelişmiş yüzey hazırlama ve kaplama süreçleri, boya yapışmasının en iyi seviyede olmasını ve uzun vadede görünümün korunmasını sağlar; toz boya sistemleri solmaya, pudralanmaya ve korozyona karşı dirençli, eşit kaplamalar uygular. Üretim tesisleri içindeki çevre kontrol sistemleri, malzeme davranışının ve kaplama kalitesinin tutarlı olmasına katkı sağlayan optimal sıcaklık ve nem koşullarını sağlar. İstatistiksel süreç kontrol yöntemlerinin uygulanması, kritik üretim parametrelerinin gerçek zamanlı olarak izlenmesine olanak tanıyarak sapmalar meydana geldiğinde anında düzeltici önlemlerin alınmasını sağlar. Bu kapsamlı üretim mükemmellik yaklaşımı, her ısı köprüsüz alüminyum kapı ve pencere sisteminin belirlenen performans kriterlerini karşılamasını veya aşmasını ve öngörülen kullanım ömrü boyunca güvenilir hizmet sunmasını garanti eder.