energyefficient thermal break aluminum doors and windows supplier

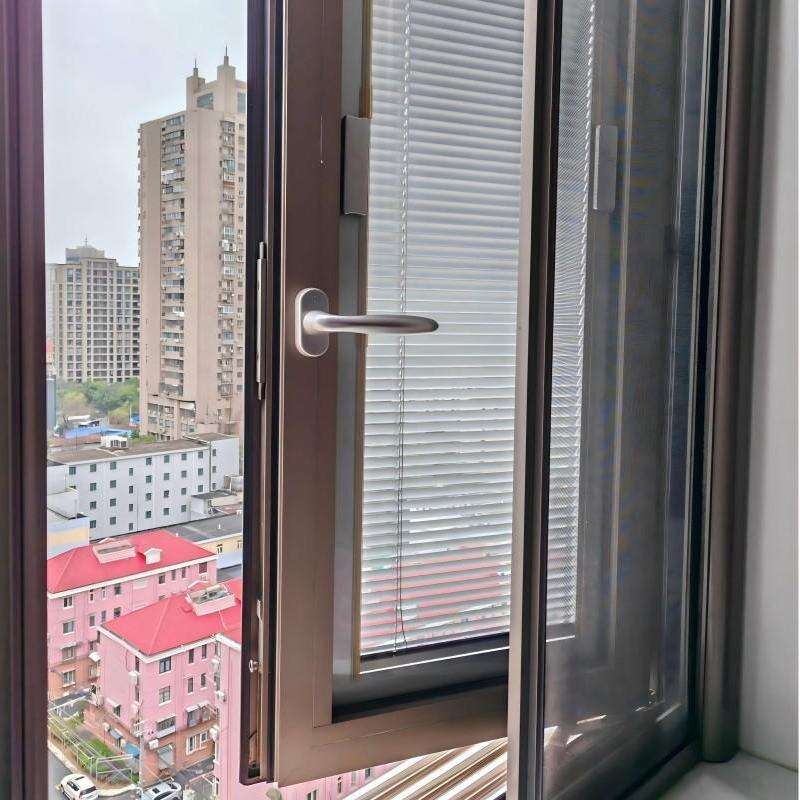

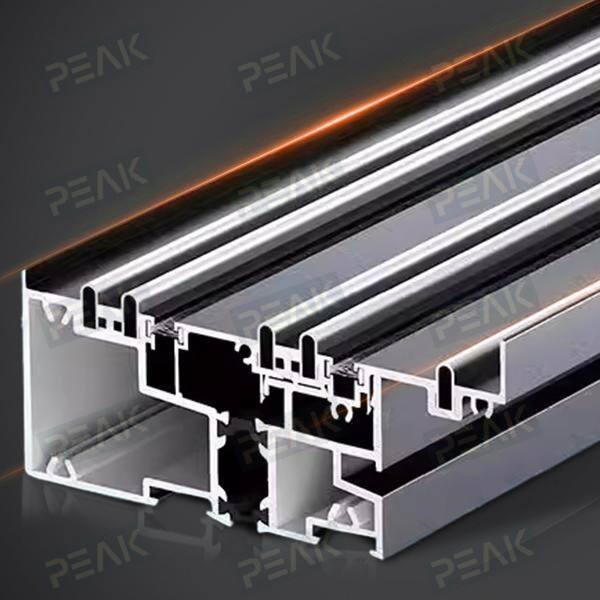

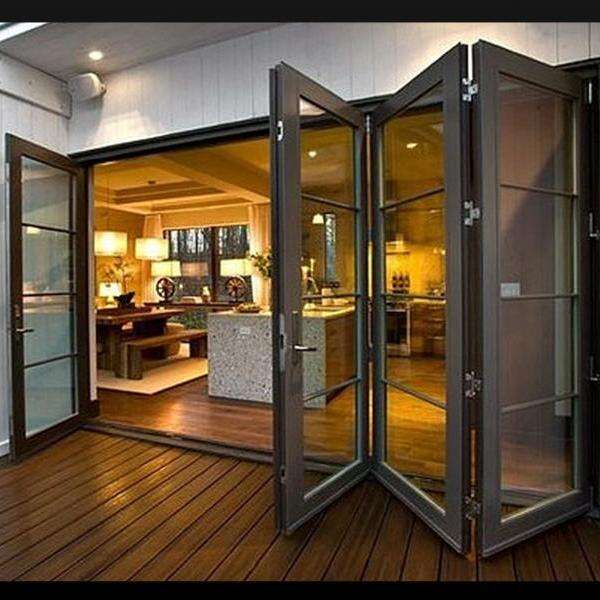

An energy-efficient thermal break aluminum doors and windows supplier represents the forefront of modern building envelope technology, delivering superior performance solutions for residential, commercial, and industrial applications. These specialized manufacturers combine advanced aluminum engineering with cutting-edge thermal insulation technology to create fenestration systems that dramatically reduce energy consumption while maintaining structural integrity and aesthetic appeal. The core function of an energy-efficient thermal break aluminum doors and windows supplier centers on providing building professionals and property owners with fenestration products that minimize heat transfer between interior and exterior environments. This is achieved through sophisticated thermal break technology, which incorporates non-conductive materials between aluminum frame sections, effectively interrupting thermal bridging that traditionally occurs in standard aluminum systems. The technological features employed by leading energy-efficient thermal break aluminum doors and windows suppliers include multi-chamber frame designs, precision-engineered thermal barriers, advanced weatherstripping systems, and high-performance glazing options. These components work synergistically to create fenestration solutions that exceed industry standards for thermal performance, air infiltration resistance, and structural durability. Modern suppliers utilize computer-aided design systems and thermal modeling software to optimize frame geometries and thermal break placement, ensuring maximum energy efficiency without compromising structural performance. Applications for products from energy-efficient thermal break aluminum doors and windows suppliers span diverse sectors including luxury residential developments, commercial office buildings, educational facilities, healthcare institutions, and industrial complexes. These systems are particularly valuable in climate-controlled environments where energy costs represent significant operational expenses. The versatility of aluminum allows suppliers to customize solutions for specific architectural requirements while maintaining consistent thermal performance characteristics across different product configurations and sizes.