energyefficient thermal break aluminum doors and windows factory

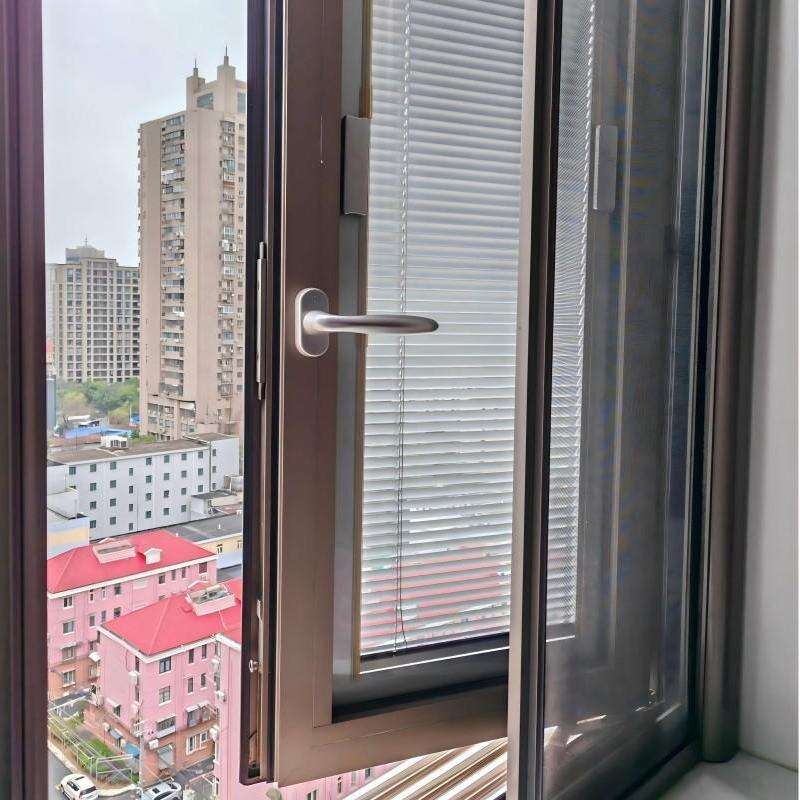

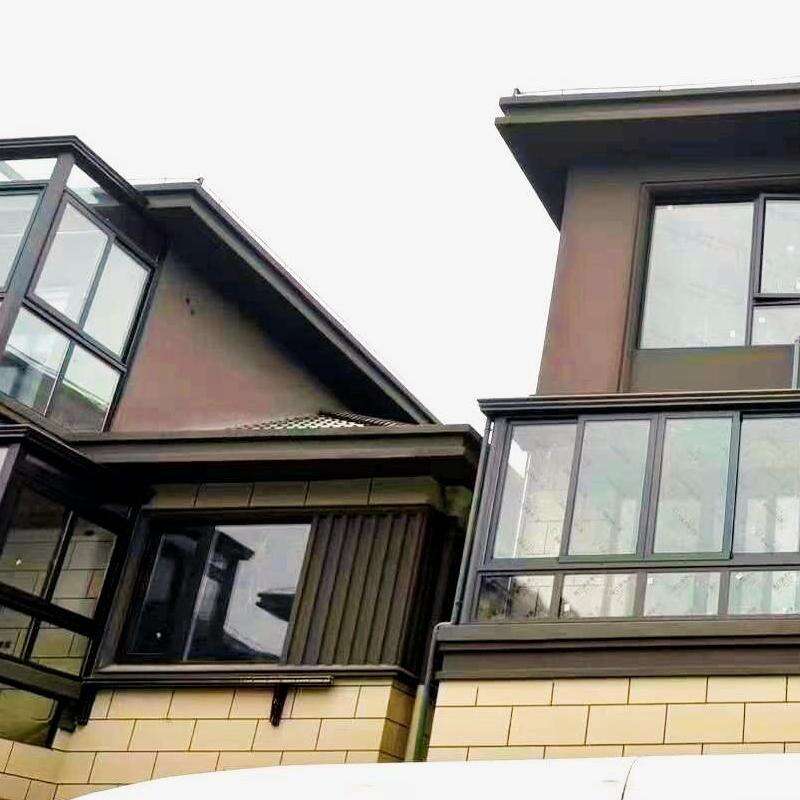

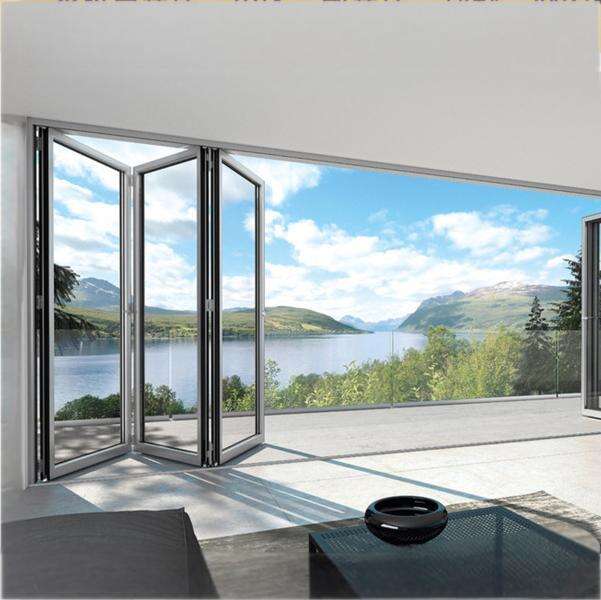

An energy-efficient thermal break aluminum doors and windows factory represents a cutting-edge manufacturing facility dedicated to producing premium fenestration products that combine advanced thermal performance with superior durability. These specialized manufacturing plants focus on creating aluminum door and window systems that incorporate thermal break technology, which effectively interrupts heat transfer between interior and exterior environments. The primary function of an energy-efficient thermal break aluminum doors and windows factory involves precision engineering polyamide strips or thermal barriers within aluminum frames to create insulated pathways that significantly reduce thermal conductivity. This innovative manufacturing approach ensures that buildings maintain consistent internal temperatures while minimizing energy consumption for heating and cooling systems. The technological features of these factories include state-of-the-art extrusion equipment, precision cutting machinery, advanced glazing systems, and automated assembly lines that guarantee consistent quality and performance. Modern facilities utilize computer-controlled manufacturing processes that ensure precise measurements and optimal thermal break placement throughout each product. Quality control systems within these factories employ rigorous testing protocols to verify thermal performance, structural integrity, and weather resistance of finished products. The applications for products manufactured in energy-efficient thermal break aluminum doors and windows factories span residential, commercial, and industrial construction projects. These facilities produce various window styles including casement, sliding, awning, and fixed windows, alongside door systems such as entrance doors, sliding patio doors, and curtain wall systems. The manufacturing process incorporates multiple aluminum alloy grades optimized for different performance requirements and architectural specifications. Environmental sustainability remains a core focus, with many factories implementing recycling programs for aluminum waste and utilizing renewable energy sources to power manufacturing operations. Advanced surface treatment processes including powder coating and anodizing provide enhanced durability and aesthetic appeal while maintaining thermal efficiency standards.