Advanced Glazing Compatibility Enables Maximum Energy Performance Customization

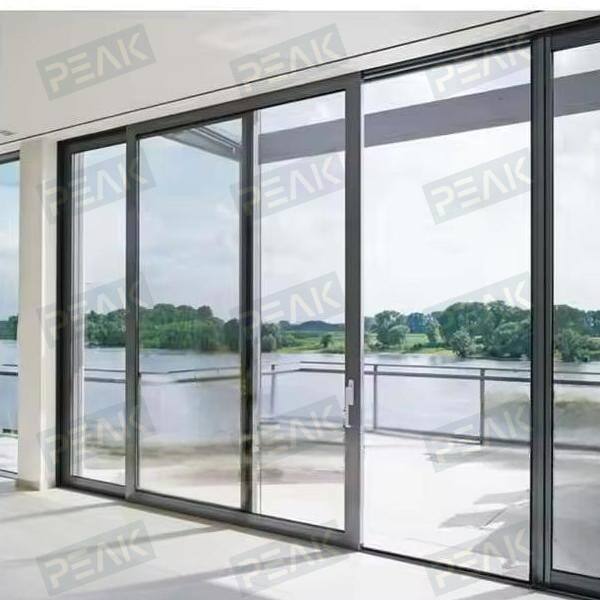

The design flexibility of heat insulation thermal break aluminum doors and windows extends to their exceptional compatibility with advanced glazing systems, enabling property owners to achieve maximum energy performance through customized glass configurations tailored to specific climate requirements and building orientations. These fenestration systems accommodate various glazing thicknesses and configurations, including double-pane, triple-pane, and specialized energy-efficient units with low-emissivity coatings, gas fills, and warm-edge spacer systems. The frame design incorporates adjustable glazing pockets that can accommodate different glass thicknesses while maintaining optimal thermal performance and structural integrity throughout the installation. Advanced glazing compatibility means that heat insulation thermal break aluminum doors and windows can integrate with the latest glass technologies, including electrochromic smart glass, vacuum-insulated units, and specialized solar control glazing that automatically adjusts light transmission based on environmental conditions. The structural engineering of the frame system ensures proper support for heavy glazing units while maintaining precise alignment and preventing thermal stress that could compromise the glazing seals or frame performance. Professional installation techniques specific to these systems ensure that the glazing integration maintains the thermal break integrity while providing weather-tight sealing that prevents air and moisture infiltration around the glass perimeter. The glazing compatibility extends to various architectural styles and design preferences, allowing for clear glass, tinted options, decorative patterns, and energy-efficient coatings that enhance both aesthetic appeal and functional performance. Quality assurance protocols verify that each glazing installation maintains the designed thermal performance ratings while providing long-term reliability and weather resistance. Property owners benefit from the ability to upgrade or modify their glazing systems as technology advances or building requirements change, with the frame system designed to accommodate future improvements in glass technology. The advanced glazing compatibility of heat insulation thermal break aluminum doors and windows also supports specialized applications such as hurricane-resistant glazing, security glass, and fire-rated assemblies while maintaining superior energy efficiency performance.