Advanced Customization and Design Flexibility

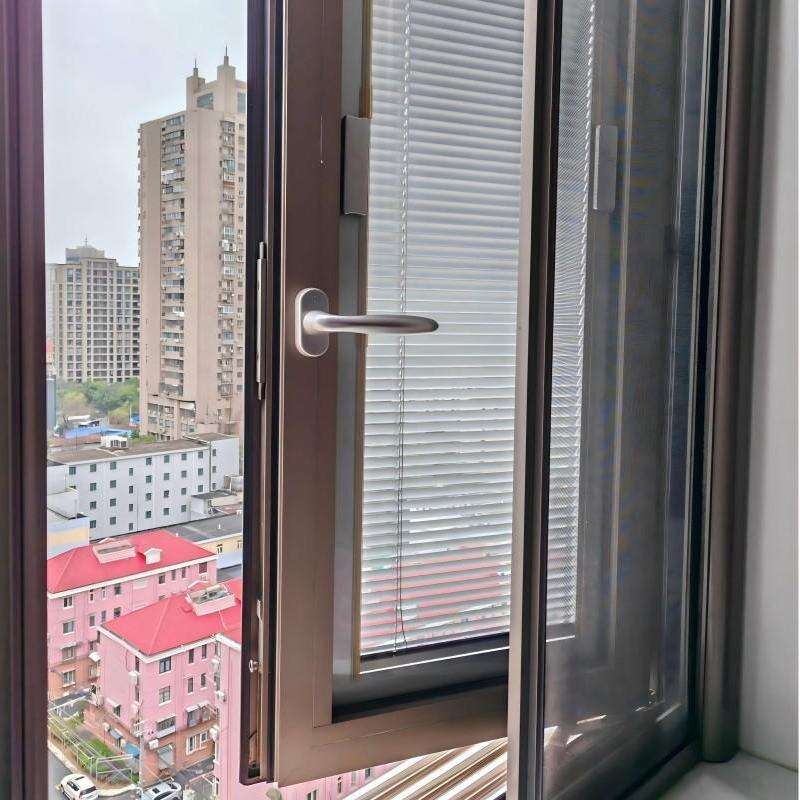

The sophisticated customization capabilities of highend thermal break aluminum doors and windows enable architects and property owners to achieve precise design visions while maintaining superior performance characteristics across diverse architectural applications and aesthetic preferences. Advanced manufacturing technologies support virtually unlimited dimensional configurations, allowing custom sizing for unique architectural openings without compromising structural integrity or thermal performance specifications. Comprehensive color options include standard powder coating finishes, premium metallic effects, wood grain textures, and specialized architectural coatings that integrate seamlessly with existing building aesthetics or create distinctive design statements. The modular frame design approach accommodates various glazing configurations including single glazing, double glazing, triple glazing, and specialized performance glass options such as low-emissivity coatings, laminated safety glass, and acoustic dampening systems. Hardware selection encompasses multiple operating styles including casement, awning, sliding, tilt-and-turn, and fixed configurations that match functional requirements and design preferences for each specific application. Specialized architectural features such as integrated blinds, decorative glazing bars, and custom mullion patterns provide additional design flexibility while maintaining the superior performance characteristics of the complete window system. The precise engineering capabilities enable integration with building automation systems, motorized operation controls, and smart home technologies that enhance convenience and operational efficiency. Custom fabrication services accommodate unique project requirements including curved frames, oversized panels, and specialized installation configurations that address challenging architectural conditions. Professional design consultation services ensure optimal specification decisions that balance aesthetic objectives with performance requirements and budget considerations, while comprehensive technical support throughout the project lifecycle ensures successful implementation and long-term satisfaction with these premium window systems that represent significant investments in building performance and occupant comfort enhancement.