Comprehensive Customization and Design Flexibility Solutions

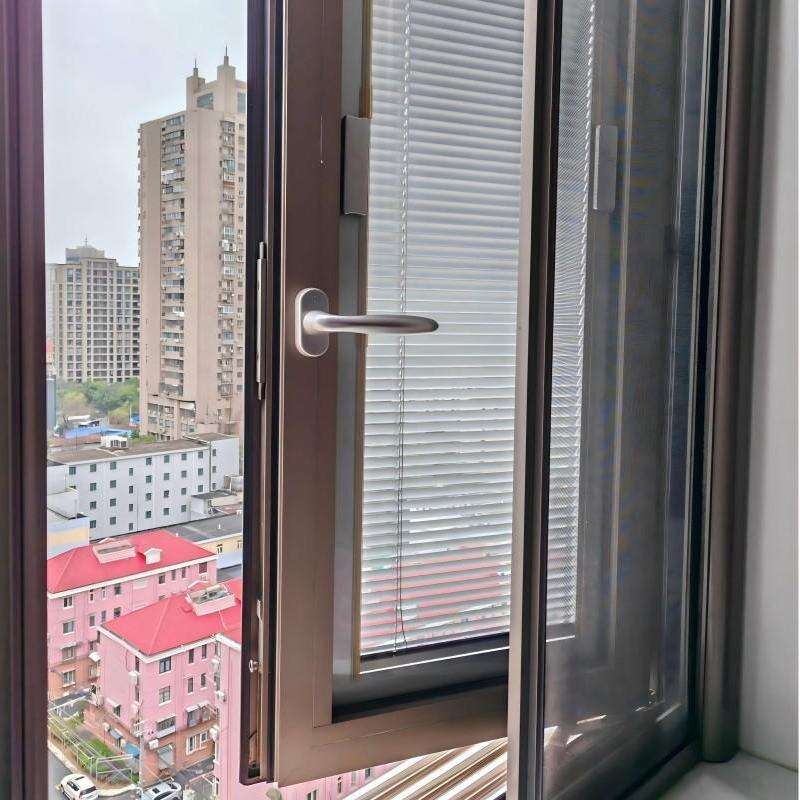

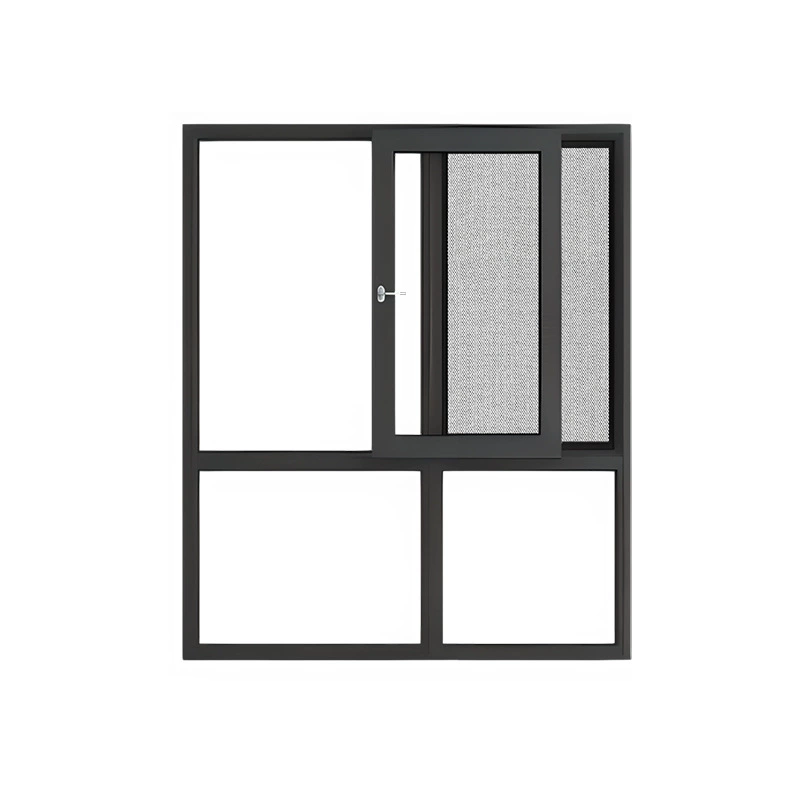

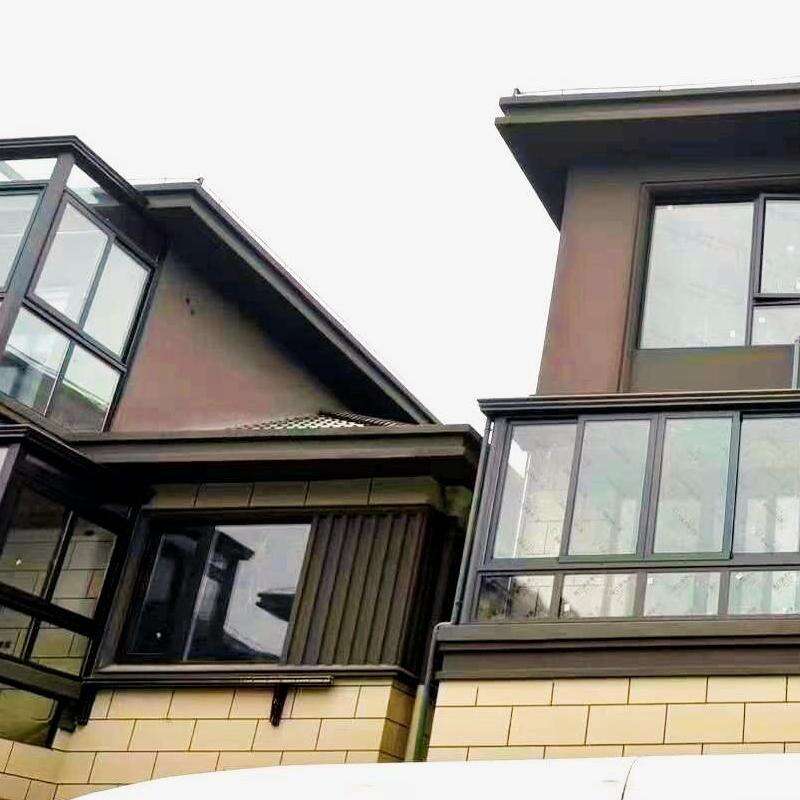

The exceptional design flexibility and customization capabilities offered by a professional highrise building thermal break aluminum doors and windows manufacturer enable architects and developers to achieve distinctive architectural visions while maintaining optimal performance standards. Unlike standard window manufacturers who offer limited product variations, specialized highrise manufacturers possess the engineering expertise, manufacturing capabilities, and technical resources necessary to create fully customized solutions tailored to specific project requirements. This customization begins with extensive profile design options that can accommodate various architectural styles, from contemporary curtain wall systems to traditional punched window configurations. A dedicated highrise building thermal break aluminum doors and windows manufacturer maintains comprehensive extrusion capabilities, allowing them to create unique profile shapes, dimensions, and thermal break configurations that align with specific design requirements and performance targets. The color and finish options available through professional manufacturers extend far beyond standard powder coating selections to include anodizing, wood grain transfers, stone-like finishes, and custom color matching services. These advanced finishing capabilities enable seamless integration with architectural design concepts while providing superior weather resistance and aesthetic longevity. Glazing integration represents another area where specialized manufacturers excel, offering compatibility with various glazing technologies including triple glazing, dynamic glass, integrated photovoltaics, and specialized coatings for glare control and energy management. The engineering support provided by established manufacturers includes thermal modeling, structural analysis, and performance optimization services that help architects achieve specific building performance goals while maintaining design integrity. Project-specific engineering extends to hardware integration, where manufacturers can accommodate various operators, locking systems, and automated controls while maintaining thermal break continuity and weather seal performance. The manufacturing flexibility inherent in professional operations allows for mixed product types within single projects, including operable windows, fixed glazing, doors, and specialty configurations such as corner windows or curved assemblies. Quality assurance programs implemented by reputable manufacturers include prototype development, performance testing, and design validation services that ensure customized solutions meet or exceed specified performance requirements. Installation support for customized systems includes detailed shop drawings, installation sequences, and field coordination services that account for unique design features and integration challenges. The comprehensive approach to customization provided by professional highrise building thermal break aluminum doors and windows manufacturer enables architectural creativity while ensuring long-term performance reliability and building code compliance.