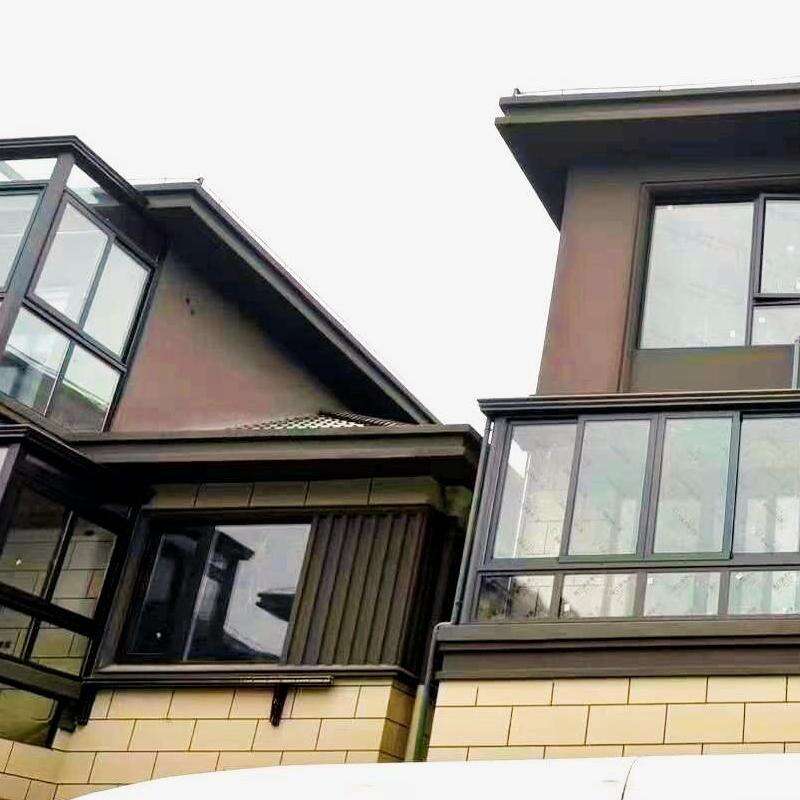

Modern homeowners increasingly recognize that energy efficiency extends far beyond the main living areas of their homes. Sunrooms, once considered purely recreational spaces, now represent significant opportunities for both energy savings and year-round comfort enhancement. The key to maximizing these benefits lies in selecting the right fenestration systems, particularly advanced sunroom thermal break aluminum doors and windows that deliver superior insulation properties while maintaining the aesthetic appeal that makes these spaces so desirable.

The integration of thermal break technology into aluminum fenestration systems represents a revolutionary advancement in building envelope performance. Traditional aluminum frames, while durable and aesthetically pleasing, have historically suffered from significant thermal conductivity issues that compromise energy efficiency. Contemporary thermal break designs effectively interrupt this heat transfer pathway, creating a barrier that dramatically reduces energy loss while maintaining the structural integrity and visual appeal that aluminum systems provide.

Energy savings potential in sunroom applications becomes particularly significant when considering the extensive glazed surface area typical of these spaces. Unlike conventional rooms with limited window coverage, sunrooms feature floor-to-ceiling glass installations that can represent hundreds of square feet of potential energy exchange points. Properly specified thermal break systems can reduce heat transfer by up to sixty percent compared to conventional aluminum frames, translating into substantial utility cost reductions over the system lifespan.

Understanding Thermal Break Technology in Aluminum Systems

Engineering Principles Behind Thermal Breaks

Thermal break technology operates on the fundamental principle of interrupting conductive heat transfer pathways within aluminum frame assemblies. The process involves strategically inserting low-conductivity materials, typically polyamide compounds reinforced with glass fibers, between the interior and exterior aluminum sections. This creates a thermal barrier that prevents heat from conducting directly through the frame material while maintaining structural continuity necessary for operational performance and wind load resistance.

The engineering sophistication behind modern thermal break systems extends beyond simple material insertion. Advanced designs incorporate multiple thermal barriers, optimized geometry configurations, and precision manufacturing tolerances that ensure consistent performance across varying environmental conditions. These systems undergo rigorous testing protocols including thermal cycling, structural loading, and long-term durability assessments to validate their performance characteristics under real-world operating conditions.

Material Science Advantages

Contemporary thermal break materials represent decades of polymer science advancement, specifically engineered to address the unique challenges of fenestration applications. These compounds must simultaneously provide thermal isolation, structural strength, dimensional stability, and long-term durability under extreme temperature variations. Advanced polyamide formulations incorporate glass fiber reinforcement that provides tensile strength comparable to aluminum while maintaining thermal conductivity values hundreds of times lower than metallic alternatives.

The material selection process for thermal break applications considers multiple performance criteria including thermal expansion coefficients, moisture absorption characteristics, ultraviolet radiation resistance, and chemical compatibility with aluminum alloys. This comprehensive approach ensures that thermal break systems maintain their performance characteristics throughout extended service life cycles while contributing to overall system reliability and occupant comfort.

Energy Performance Characteristics and Quantified Benefits

Thermal Transmission Values and Measurements

Energy performance evaluation for sunroom thermal break aluminum doors and windows relies on standardized thermal transmission measurements that quantify heat transfer rates under controlled laboratory conditions. U-factor values, expressed in British thermal units per hour per square foot per degree Fahrenheit, provide the primary metric for comparing thermal performance across different system configurations. Premium thermal break systems typically achieve U-factors ranging from 0.25 to 0.35, representing substantial improvements over conventional aluminum systems that often exceed 0.65.

Condensation resistance ratings provide additional performance indicators that directly impact occupant comfort and building durability. These ratings, expressed on a scale from zero to one hundred, quantify the system's ability to resist surface condensation under standardized temperature and humidity conditions. High-performance thermal break systems routinely achieve condensation resistance ratings exceeding seventy, ensuring comfortable interior conditions while minimizing moisture-related building envelope concerns.

Seasonal Energy Consumption Analysis

Comprehensive energy analysis reveals that properly specified thermal break systems deliver year-round performance benefits that extend beyond simple heating season improvements. During cooling seasons, reduced thermal conductivity minimizes heat gain through frame assemblies, reducing air conditioning loads and associated energy consumption. Winter performance benefits include decreased heat loss rates that reduce heating system runtime while improving interior surface temperatures and occupant comfort levels.

Quantified energy savings vary based on climate zone, building orientation, and glazing specifications, but typical installations demonstrate fifteen to thirty percent reductions in fenestration-related energy consumption. These savings compound over system lifespans that often exceed thirty years, creating substantial cumulative energy cost reductions that justify premium system investments while contributing to environmental sustainability objectives.

Installation Considerations and System Integration

Structural Requirements and Load Considerations

Successful installation of advanced thermal break systems requires comprehensive understanding of structural load paths and building envelope integration requirements. Sunroom applications present unique challenges including large glazed openings, multiple thermal zones, and exposure to extreme weather conditions. Proper structural analysis must account for wind loads, snow loads, seismic considerations, and thermal movement while ensuring that thermal break components maintain their integrity under all anticipated loading conditions.

Foundation and rough opening preparation assumes critical importance in thermal break system installations. Precise dimensional control, proper flashing integration, and thermal bridging elimination require detailed coordination between multiple building trades. Installation specifications must address vapor barrier continuity, insulation placement, and air sealing details that complement the thermal break system performance while ensuring long-term building envelope durability.

Quality Control and Performance Verification

Installation quality control protocols ensure that thermal break systems achieve their designed performance levels throughout their service lifespans. These protocols encompass pre-installation material inspections, dimensional verification procedures, and post-installation performance testing that validates thermal and structural performance characteristics. Thermal imaging surveys can identify installation defects, thermal bridging concerns, and air leakage issues that compromise system performance.

Long-term performance maintenance requires periodic inspection and preventive maintenance procedures that preserve thermal break integrity while ensuring operational reliability. These procedures include hardware lubrication, weatherstripping replacement, drainage system cleaning, and thermal break component inspection for signs of degradation or damage that could compromise energy performance.

Cost-Benefit Analysis and Return on Investment

Initial Investment Considerations

Premium thermal break systems typically command price premiums of twenty to forty percent over conventional aluminum alternatives, reflecting the advanced materials, precision manufacturing, and enhanced performance characteristics these systems provide. However, comprehensive cost-benefit analysis must consider not only initial acquisition costs but also long-term energy savings, maintenance requirements, and potential utility rebates or tax incentives that offset premium investments.

Project-specific cost analysis should incorporate local energy rates, climate conditions, and building usage patterns to accurately project energy savings potential. Professional energy modeling can quantify expected performance benefits while identifying optimization opportunities that maximize return on investment through strategic system selection and specification development.

Long-Term Value Proposition

The value proposition for thermal break systems extends beyond simple energy cost reductions to encompass improved occupant comfort, reduced maintenance requirements, and enhanced property values. Comfortable sunroom environments throughout all seasons increase usable space and contribute to overall property appeal while advanced fenestration systems signal quality construction that supports premium property valuations.

Environmental benefits associated with reduced energy consumption contribute to sustainability objectives while potentially qualifying for green building certification credits and associated marketing advantages. These indirect benefits, while difficult to quantify precisely, represent additional value components that support premium system investments in both residential and commercial applications.

Future Technologies and Industry Developments

Advanced Material Innovations

Ongoing material science research continues advancing thermal break technology through development of next-generation polymer compounds with enhanced performance characteristics. These innovations focus on improving thermal resistance, structural strength, and durability while reducing material costs and manufacturing complexity. Emerging technologies include aerogel-enhanced thermal breaks, phase-change material integration, and smart materials that adapt their properties based on environmental conditions.

Manufacturing process improvements enable more precise control over thermal break geometry and assembly procedures, resulting in more consistent performance and reduced quality variations. Advanced extrusion techniques, automated assembly systems, and real-time quality monitoring contribute to improved product reliability while supporting cost reduction initiatives that make premium systems more accessible to broader market segments.

Smart System Integration

Integration of smart building technologies with advanced fenestration systems creates opportunities for dynamic performance optimization based on real-time environmental conditions and occupancy patterns. Sensor networks can monitor thermal performance, identify maintenance requirements, and optimize HVAC system operation to maximize energy efficiency while maintaining optimal comfort conditions.

Future developments may include self-monitoring thermal break systems that provide real-time performance feedback, predictive maintenance alerts, and automatic adjustment capabilities that optimize energy performance throughout changing seasonal conditions. These technologies represent the next evolution in fenestration system sophistication, building upon the proven benefits of thermal break technology to create truly intelligent building envelope solutions.

FAQ

What maintenance requirements apply to thermal break aluminum systems in sunroom applications

Thermal break aluminum systems require minimal maintenance compared to other fenestration materials, but regular attention ensures optimal performance throughout their service life. Annual inspections should verify drainage system functionality, weatherstripping condition, and hardware operation while thermal imaging surveys every few years can identify any thermal bridging concerns. Professional maintenance typically includes lubricating moving components, cleaning drainage channels, and inspecting thermal break integrity for any signs of degradation or damage.

How do thermal break systems perform in extreme climate conditions

Advanced thermal break systems excel in extreme climates through engineered material selections and design configurations that accommodate significant temperature variations while maintaining structural integrity. Cold climate performance benefits include reduced condensation risks and improved interior comfort, while hot climate applications benefit from reduced cooling loads and enhanced occupant comfort. Proper system specification considers local climate data to optimize performance for specific environmental conditions.

Can existing sunroom aluminum systems be upgraded with thermal break technology

Retrofitting existing aluminum systems with thermal break technology typically requires complete frame replacement due to the integrated nature of thermal break design and manufacturing processes. However, comprehensive renovation projects can incorporate thermal break systems while addressing other building envelope improvements, creating opportunities for substantial energy performance enhancements. Professional evaluation can determine the most cost-effective approach for specific renovation scenarios.

What warranty coverage typically applies to thermal break fenestration systems

Premium thermal break systems typically include comprehensive warranty coverage spanning ten to twenty years for thermal break components, with separate coverage periods for glazing, hardware, and finish materials. Warranty terms should specify performance criteria, maintenance requirements, and coverage limitations while professional installation by certified contractors often extends warranty coverage and ensures proper system performance throughout the coverage period.

Table of Contents

- Understanding Thermal Break Technology in Aluminum Systems

- Energy Performance Characteristics and Quantified Benefits

- Installation Considerations and System Integration

- Cost-Benefit Analysis and Return on Investment

- Future Technologies and Industry Developments

-

FAQ

- What maintenance requirements apply to thermal break aluminum systems in sunroom applications

- How do thermal break systems perform in extreme climate conditions

- Can existing sunroom aluminum systems be upgraded with thermal break technology

- What warranty coverage typically applies to thermal break fenestration systems