Comprehensive Manufacturing Excellence and Quality Assurance Systems

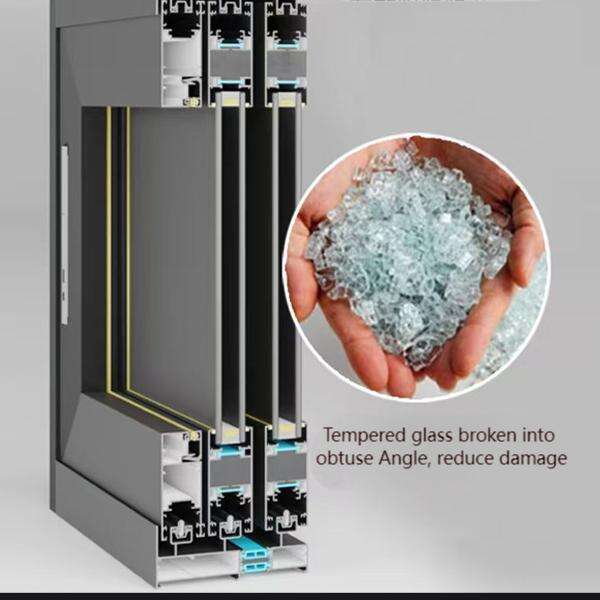

Distinguished soundproof thermal break aluminum doors and windows factory operations implement comprehensive manufacturing excellence programs that encompass every aspect of production, from raw material selection through final product delivery and installation support. Manufacturing excellence begins with careful supplier qualification processes that ensure aluminum extrusions, thermal break materials, glazing units, hardware components, and weathersealing systems meet strict quality specifications and performance requirements. Advanced manufacturing facilities utilize computer-controlled equipment for cutting, machining, welding, and assembly operations that maintain precise tolerances and consistent quality characteristics throughout production runs. Quality assurance systems incorporate multiple inspection points, performance testing procedures, and documentation requirements that verify compliance with international standards and customer specifications. The soundproof thermal break aluminum doors and windows factory approach includes comprehensive employee training programs that ensure skilled craftsmanship, proper handling procedures, and thorough understanding of quality requirements at every production stage. Automated systems monitor critical manufacturing parameters, including thermal break insertion forces, welding temperatures, glazing seal integrity, and hardware adjustment specifications, while generating detailed records for traceability and continuous improvement initiatives. Professional testing laboratories evaluate thermal performance, acoustic characteristics, structural strength, weather resistance, and operational durability using standardized test methods and sophisticated equipment. Comprehensive quality management systems ensure consistent product performance, minimize manufacturing variations, and provide detailed documentation for warranty support and performance verification. Customer service programs include technical support, installation guidance, maintenance recommendations, and responsive warranty service that protects long-term investment value. The manufacturing excellence approach delivers superior products that consistently meet or exceed performance expectations while providing reliable service throughout extended operational lifecycles. Property owners benefit from predictable performance, minimal maintenance requirements, comprehensive warranty protection, and professional support services that ensure optimal long-term value and satisfaction.