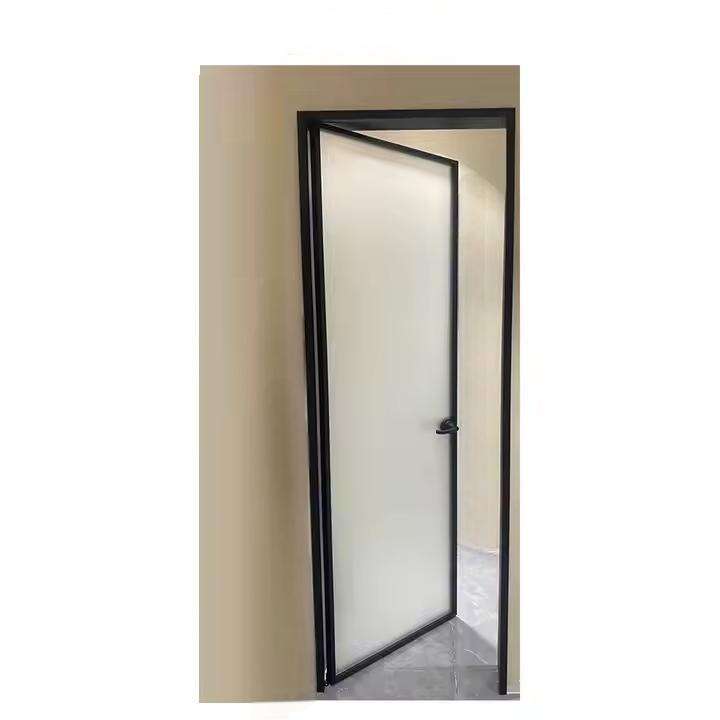

soundproof thermal break aluminum doors and windows manufacturer

A soundproof thermal break aluminum doors and windows manufacturer represents a specialized company that designs, produces, and distributes advanced fenestration systems combining acoustic insulation with thermal efficiency. These manufacturers utilize cutting-edge aluminum extrusion technology integrated with thermal break materials to create high-performance building solutions. The primary function of these systems involves creating barriers against both sound transmission and heat transfer, making them essential for modern construction projects requiring energy efficiency and noise reduction. The technological features encompass multi-chamber aluminum profiles with polyamide thermal breaks, specialized gasket systems, and precision-engineered hardware components. Advanced manufacturing processes include computer-controlled extrusion, precision cutting, welding techniques, and quality control systems ensuring consistent product performance. The thermal break technology involves inserting non-conductive materials between interior and exterior aluminum sections, preventing thermal bridging while maintaining structural integrity. Sound dampening capabilities are achieved through strategic frame design, multiple sealing layers, and acoustic glazing compatibility. Applications span residential developments, commercial buildings, educational facilities, healthcare institutions, hospitality venues, and industrial complexes. These products serve environments where noise pollution control and energy conservation are critical requirements. The manufacturing process involves sourcing premium aluminum alloys, implementing automated production lines, and conducting rigorous testing protocols. Quality assurance measures include thermal performance testing, acoustic rating verification, weather resistance evaluation, and durability assessments. The soundproof thermal break aluminum doors and windows manufacturer must comply with international standards including energy efficiency ratings, acoustic classification systems, and structural performance requirements. Distribution networks typically encompass direct sales, authorized dealers, and contractor partnerships, ensuring widespread availability and professional installation support throughout various markets.