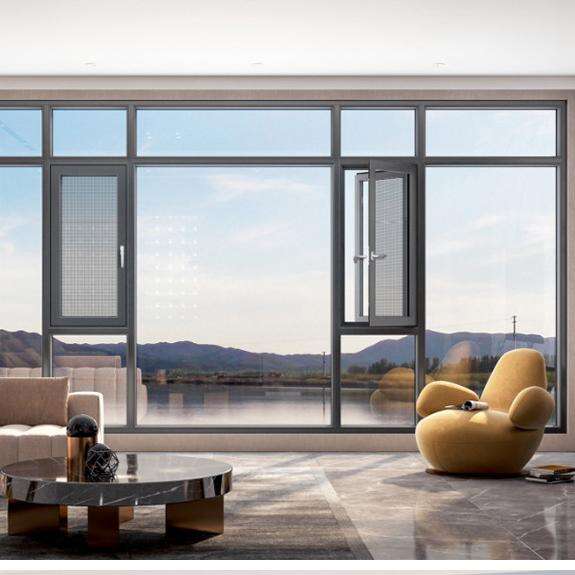

thermal break aluminum windows and doors manufacturer

A thermal break aluminum windows and doors manufacturer represents the pinnacle of modern fenestration technology, combining the strength and durability of aluminum with advanced thermal insulation properties. These specialized manufacturers focus on creating window and door systems that effectively interrupt the thermal bridge between interior and exterior aluminum components, significantly reducing heat transfer and energy loss. The thermal break technology involves inserting a low-conductivity material, typically polyamide strips or thermal barriers, between the interior and exterior aluminum profiles. This innovative approach prevents the direct conduction of heat and cold through the aluminum frame, creating a more energy-efficient building envelope. Leading thermal break aluminum windows and doors manufacturers utilize state-of-the-art production facilities equipped with precision cutting systems, automated assembly lines, and quality control mechanisms to ensure consistent product performance. The manufacturing process involves extruding aluminum profiles, precision cutting thermal break materials, and assembling components using specialized machinery that maintains tight tolerances and structural integrity. These manufacturers typically offer comprehensive product ranges including casement windows, sliding windows, tilt-and-turn systems, folding doors, sliding patio doors, and commercial curtain wall systems. Modern thermal break aluminum windows and doors manufacturers incorporate advanced glazing technologies, multi-point locking systems, and weather sealing solutions to maximize energy efficiency, security, and weather resistance. The applications span residential construction, commercial buildings, institutional facilities, and high-performance architectural projects where energy efficiency, durability, and aesthetic appeal are paramount considerations.