top thermal break aluminum doors and windows brand

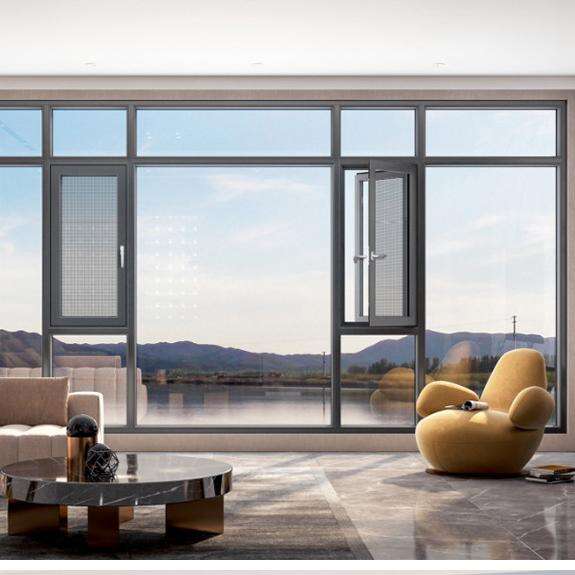

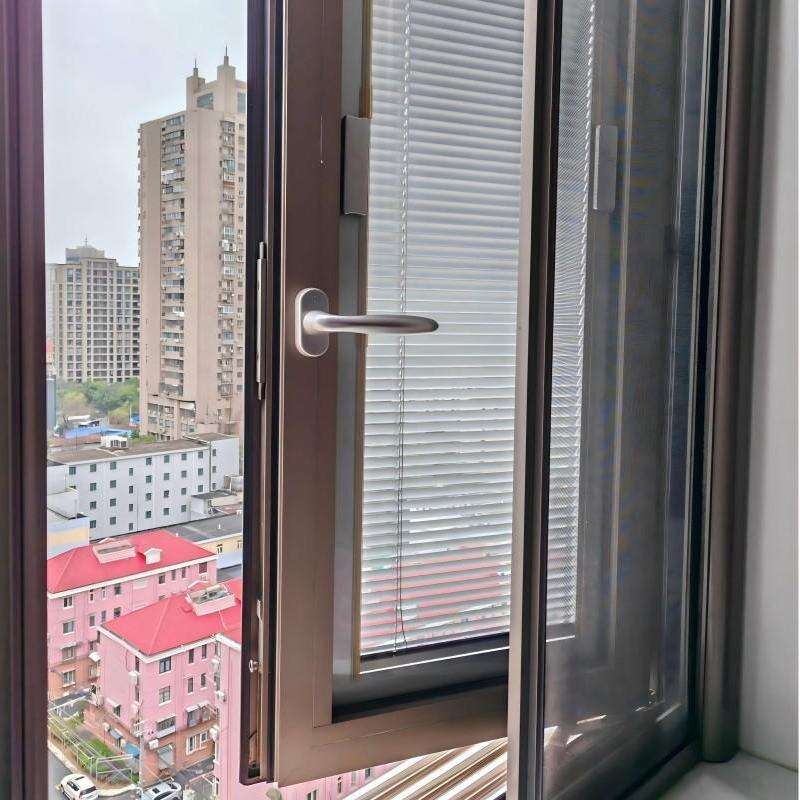

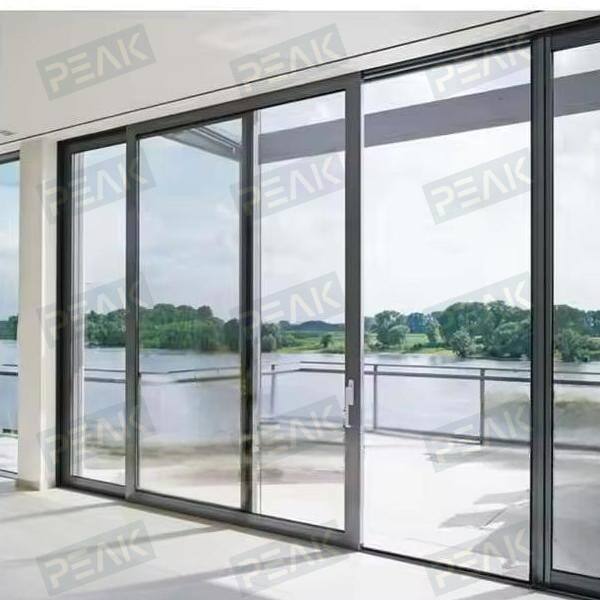

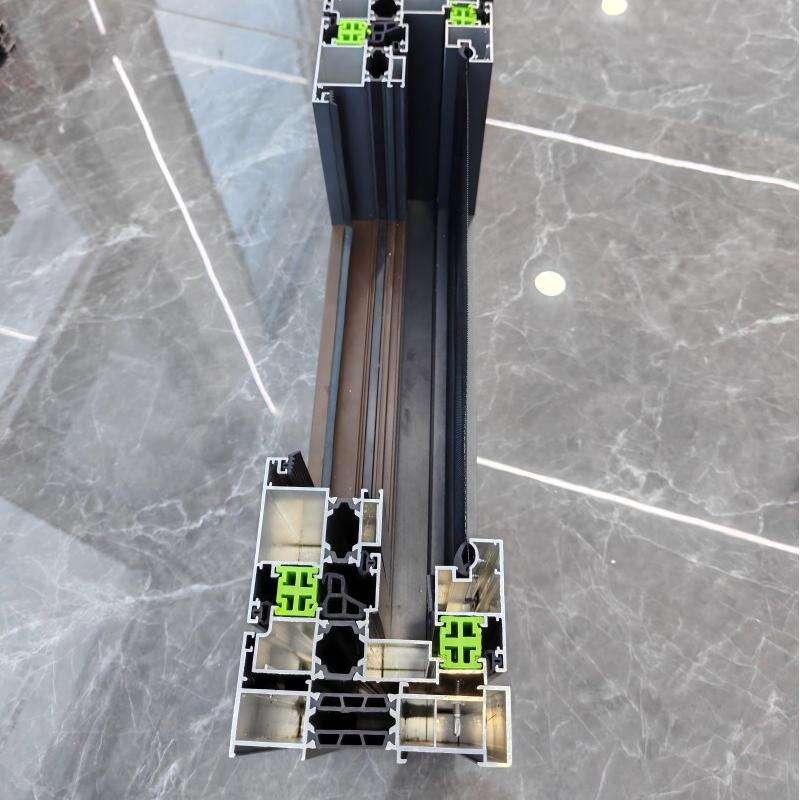

The top thermal break aluminum doors and windows brand represents cutting-edge innovation in modern architectural solutions, combining superior engineering with aesthetic excellence. These premium systems utilize advanced thermal break technology that effectively separates the interior and exterior aluminum frames through specialized insulating materials, creating a barrier that significantly reduces heat transfer and energy loss. The primary function of the top thermal break aluminum doors and windows brand focuses on maximizing energy efficiency while maintaining structural integrity and visual appeal. The technological features incorporate multi-chamber polyamide strips or polyurethane foam inserts that create thermal barriers, preventing condensation and improving indoor climate control. Advanced glazing systems work in conjunction with precision-engineered frames to deliver exceptional performance across various weather conditions. The manufacturing process employs computer-controlled machinery that ensures consistent quality and precise tolerances, resulting in products that meet international standards for energy efficiency and durability. Applications for the top thermal break aluminum doors and windows brand span residential, commercial, and institutional buildings where energy conservation and comfort are priorities. Residential installations benefit from reduced heating and cooling costs, while commercial properties achieve better HVAC efficiency and occupant satisfaction. The versatile design options accommodate various architectural styles, from contemporary minimalist aesthetics to traditional building facades. Weather resistance capabilities make these systems suitable for extreme climates, coastal environments, and urban settings with high pollution levels. The top thermal break aluminum doors and windows brand integrates seamlessly with smart building technologies, supporting automated climate control systems and security features. Manufacturing quality control processes ensure consistent performance, with rigorous testing protocols that verify thermal efficiency, structural strength, and longevity. The comprehensive product range includes sliding doors, casement windows, tilt-and-turn configurations, and custom designs that meet specific project requirements while maintaining the superior thermal performance that defines this market-leading brand.