Modern homeowners increasingly recognize that balconies represent more than just outdoor extensions of their living spaces. These areas serve as crucial transition zones where interior comfort meets exterior elements, making the selection of appropriate door and window systems paramount to overall home performance. The integration of advanced thermal break technology in aluminum fenestration systems has revolutionized how we approach balcony design, offering unprecedented levels of energy efficiency, comfort, and aesthetic appeal. Understanding the complexities of balcony thermal break aluminum doors and windows customization enables property owners to make informed decisions that enhance both immediate comfort and long-term property value.

Understanding Thermal Break Technology in Aluminum Systems

The Science Behind Thermal Bridge Interruption

Thermal break technology addresses one of aluminum's primary weaknesses as a building material: its exceptional thermal conductivity. While aluminum's strength-to-weight ratio and corrosion resistance make it ideal for fenestration applications, its ability to conduct heat and cold creates thermal bridges that compromise energy efficiency. Thermal break systems interrupt these bridges by incorporating low-conductivity materials, typically polyamide or polyurethane, between interior and exterior aluminum profiles. This interruption prevents direct thermal transfer, maintaining comfortable interior temperatures while reducing energy consumption.

The effectiveness of thermal break systems depends heavily on the design and implementation of these interruption zones. Advanced systems feature multiple thermal barriers strategically positioned throughout the profile depth, creating cascading resistance to thermal transfer. Modern manufacturing techniques allow for precise control over barrier placement, ensuring optimal performance across varying climate conditions and seasonal temperature fluctuations.

Material Properties and Performance Characteristics

Contemporary thermal break materials exhibit remarkable durability and performance characteristics that complement aluminum's inherent strengths. Polyamide strips, commonly used in high-performance systems, maintain their insulating properties across extreme temperature ranges while providing structural continuity between aluminum sections. These materials resist moisture absorption, preventing degradation that could compromise thermal performance over time.

The integration of thermal break materials requires precise engineering to maintain the structural integrity of the aluminum profile while maximizing thermal resistance. Advanced extrusion techniques ensure seamless integration between materials, creating profiles that perform as unified systems rather than composite assemblies. This integration approach prevents weak points that could lead to thermal bridging or structural failure under load conditions.

Customization Options for Balcony Applications

Architectural Integration and Design Flexibility

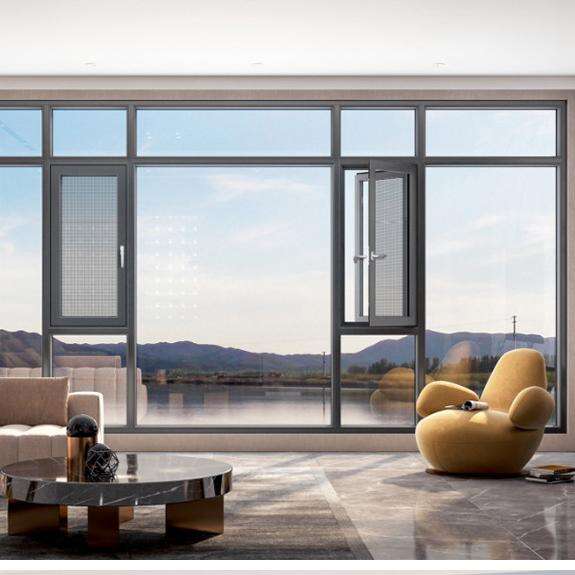

Balcony spaces present unique architectural challenges that require customized fenestration solutions. The exposure to weather elements, structural loading requirements, and integration with building facades demand careful consideration of design parameters. Customization options for balcony thermal break aluminum doors and windows encompass dimensional flexibility, opening mechanisms, glazing configurations, and finish selections that complement existing architectural elements.

Modern customization capabilities extend beyond basic dimensional adjustments to include complex geometric configurations that accommodate irregular openings or specialized architectural features. Advanced manufacturing techniques enable the production of curved profiles, angled connections, and multi-directional assemblies that maintain thermal performance while meeting specific design requirements. These capabilities allow architects and builders to implement cohesive design visions without compromising energy efficiency or structural integrity.

Hardware and Operation System Variations

The selection of appropriate hardware and operating systems significantly impacts both the functionality and thermal performance of balcony fenestration systems. Contemporary hardware options include multi-point locking mechanisms that ensure uniform compression across the entire perimeter, eliminating air infiltration paths that compromise thermal efficiency. Advanced hinge systems accommodate heavy glazing loads while maintaining smooth operation over extended service life.

Operating system customization addresses specific user preferences and functional requirements. Inward-opening configurations maximize balcony floor space utilization while providing easy cleaning access, while outward-opening systems offer improved weather resistance and interior space preservation. Tilt-and-turn mechanisms combine ventilation flexibility with security features, enabling partial opening for air circulation while maintaining weather protection. Each operating system requires specific hardware configurations optimized for thermal break profile geometries.

Energy Efficiency and Performance Benefits

Thermal Performance Optimization

The implementation of thermal break technology in balcony fenestration systems delivers measurable improvements in overall building energy performance. These improvements manifest through reduced heating and cooling loads, minimized condensation formation, and enhanced occupant comfort. Thermal break systems typically achieve U-values significantly lower than conventional aluminum profiles, with some high-performance configurations reaching values comparable to advanced composite materials.

Performance optimization extends beyond basic thermal resistance to include air infiltration control, water penetration resistance, and structural wind load capacity. Modern testing protocols evaluate these performance characteristics under simulated extreme weather conditions, ensuring reliable performance across diverse climate zones. The integration of multiple performance attributes in single system designs eliminates the need for separate solutions while maintaining cost-effectiveness.

Long-term Economic Advantages

Investment in high-performance thermal break systems generates long-term economic benefits through reduced energy consumption, extended service life, and enhanced property values. Energy savings typically offset initial investment premiums within five to seven years, with continued savings extending throughout the system's service life. The durability of aluminum profiles combined with advanced thermal break materials ensures performance maintenance over decades of service.

Maintenance requirements for thermal break systems remain minimal compared to alternative materials, reducing ongoing operational costs. The corrosion resistance of aluminum combined with the stability of thermal break materials eliminates the need for frequent replacements or major maintenance interventions. This reliability contributes to overall lifecycle cost advantages that justify initial investment decisions.

Installation and Quality Considerations

Professional Installation Requirements

The installation of balcony thermal break aluminum doors and windows customization systems requires specialized knowledge and techniques to ensure optimal performance. Proper installation directly impacts thermal efficiency, weather resistance, and structural integrity. Professional installers must understand the specific requirements of thermal break profiles, including appropriate sealant selection, flashing details, and structural anchoring methods.

Installation quality control measures include verification of dimensional accuracy, thermal barrier continuity, and weather seal integrity. Advanced installation techniques incorporate thermal imaging verification to identify potential thermal bridges or air infiltration paths before final completion. These quality assurance measures ensure that installed systems achieve their designed performance levels throughout their service life.

Quality Assurance and Testing Protocols

Comprehensive quality assurance programs for thermal break fenestration systems include material testing, manufacturing quality control, and post-installation performance verification. Material testing encompasses thermal conductivity measurement, structural load testing, and accelerated aging protocols that simulate decades of environmental exposure. Manufacturing quality control ensures consistent thermal break placement and profile dimensional accuracy across production runs.

Post-installation testing protocols verify system performance under actual operating conditions. These tests include air infiltration measurement, water penetration testing, and thermal performance verification using standardized testing procedures. Documentation of these results provides baseline performance data for warranty coverage and maintenance planning purposes.

FAQ

What makes thermal break aluminum systems superior to conventional aluminum windows for balcony applications

Thermal break aluminum systems incorporate insulating barriers that interrupt thermal conduction through the aluminum profile, significantly improving energy efficiency compared to conventional aluminum windows. This technology reduces heat transfer by up to seventy percent while maintaining aluminum's strength and durability advantages. For balcony applications, this translates to improved comfort, reduced condensation, and lower energy costs while providing superior weather resistance and structural performance.

How do customization options affect the cost and timeline of balcony window projects

Customization complexity directly impacts both project costs and delivery timelines, with standard configurations typically requiring four to six weeks for manufacturing and delivery. Complex customizations involving unique geometries, specialized hardware, or non-standard finishes may extend timelines to eight to twelve weeks. Cost premiums for customization typically range from fifteen to forty percent above standard configurations, depending on the complexity and volume of modifications required.

What maintenance is required for thermal break aluminum systems in balcony environments

Thermal break aluminum systems require minimal maintenance compared to other materials, with routine cleaning and hardware lubrication representing the primary ongoing requirements. Annual inspection of weather seals and drainage systems ensures continued performance, while hardware adjustment may be needed every three to five years depending on usage frequency. The corrosion resistance of aluminum combined with stable thermal break materials eliminates the need for refinishing or major component replacement during typical service life.

How do I determine the appropriate thermal performance requirements for my specific climate zone

Climate zone requirements are typically defined by local building codes and energy efficiency standards, with specific U-value and air infiltration requirements varying by geographic location. Professional energy consultants can perform detailed analysis considering local weather patterns, building orientation, and usage requirements to determine optimal thermal performance specifications. Most residential applications benefit from thermal break systems achieving U-values between 0.30 and 0.50 W/m²K, with colder climates requiring lower values for optimal performance.

Table of Contents

- Understanding Thermal Break Technology in Aluminum Systems

- Customization Options for Balcony Applications

- Energy Efficiency and Performance Benefits

- Installation and Quality Considerations

-

FAQ

- What makes thermal break aluminum systems superior to conventional aluminum windows for balcony applications

- How do customization options affect the cost and timeline of balcony window projects

- What maintenance is required for thermal break aluminum systems in balcony environments

- How do I determine the appropriate thermal performance requirements for my specific climate zone