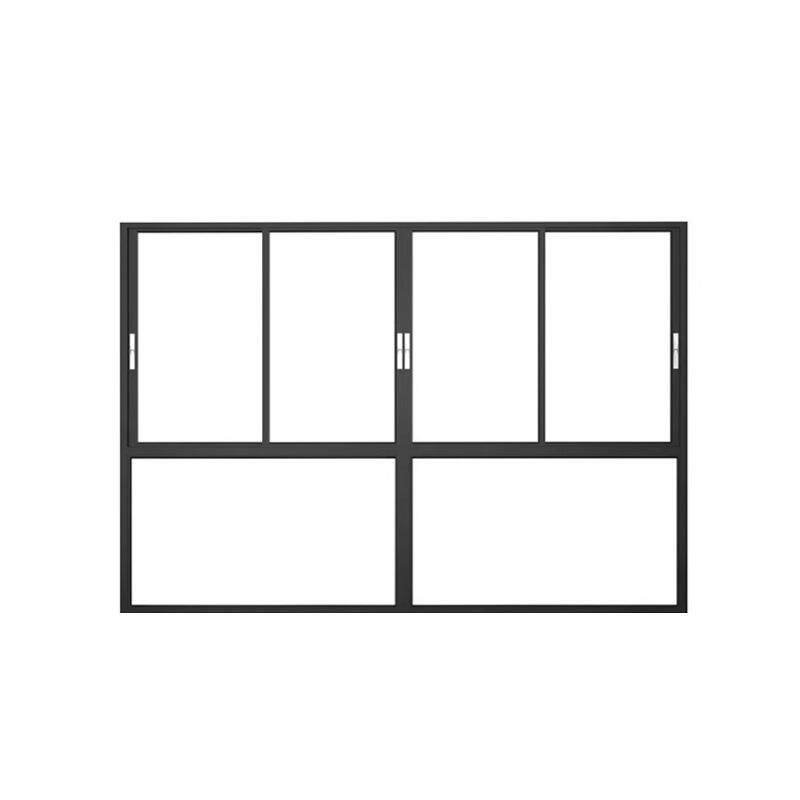

aluminium door window fabricators

Aluminium door window fabricators are specialized manufacturers who design, create, and assemble high-quality aluminum frames for doors and windows. These professionals utilize advanced manufacturing techniques and state-of-the-art equipment to produce custom-made solutions that meet specific architectural requirements. The fabrication process involves precise cutting, shaping, and joining of aluminum profiles to create durable, weather-resistant frames that offer both functionality and aesthetic appeal. Modern aluminum fabricators employ computer-aided design (CAD) systems and automated production lines to ensure accuracy and consistency in their products. They work with various aluminum alloys selected for their strength, corrosion resistance, and thermal properties. The fabrication process includes multiple stages, from initial design and material selection to final assembly and quality testing. These fabricators also integrate advanced glazing systems and hardware components to enhance performance characteristics such as thermal insulation, sound reduction, and security features. Their expertise extends to creating custom solutions for residential, commercial, and industrial applications, ensuring compliance with building codes and energy efficiency standards while maintaining architectural integrity and design aesthetics.