aluminum door and window manufacturing

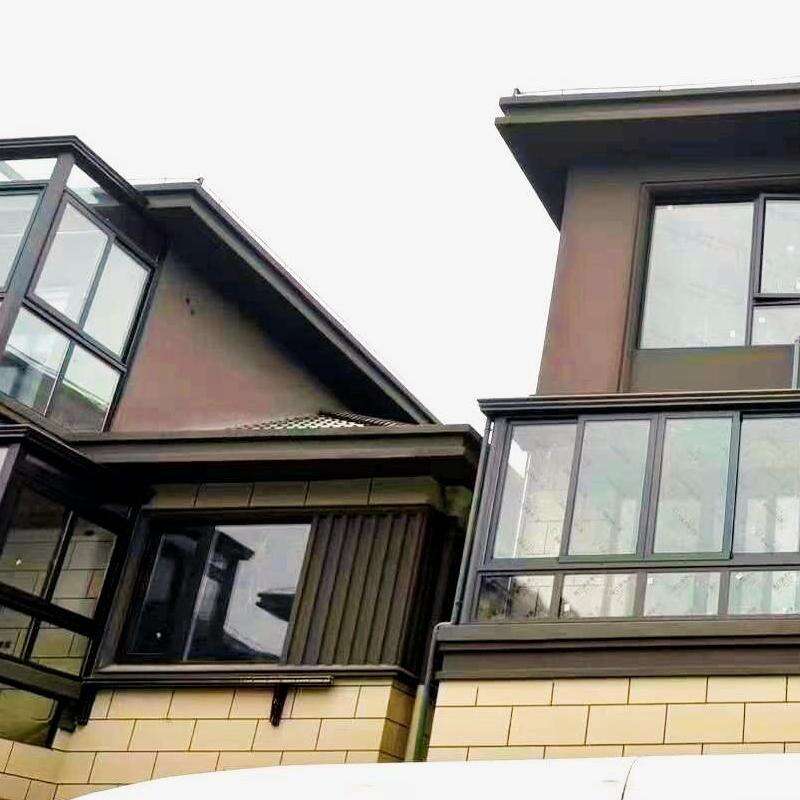

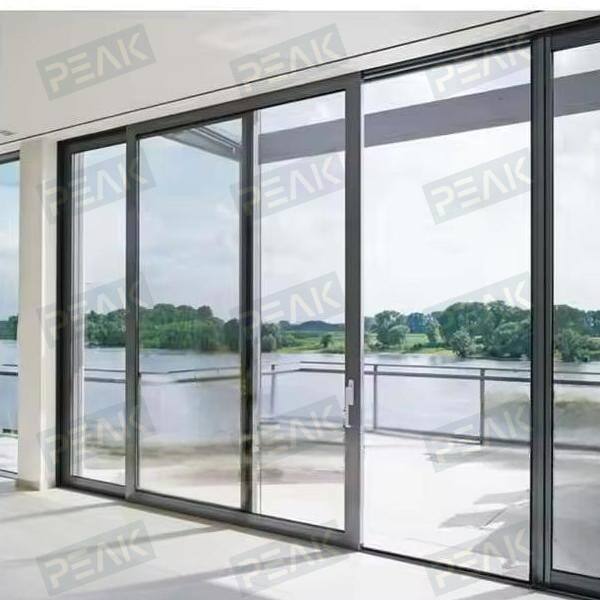

Aluminum door and window manufacturing represents a sophisticated industrial process that transforms raw aluminum materials into durable, functional architectural components for residential, commercial, and industrial applications. This comprehensive manufacturing sector combines advanced metallurgy, precision engineering, and modern fabrication techniques to produce high-quality fenestration products that meet demanding performance standards. The aluminum door and window manufacturing process begins with sourcing premium aluminum alloys, typically 6061 or 6063 grades, which offer exceptional strength-to-weight ratios and corrosion resistance properties. These materials undergo extrusion processes where heated aluminum billets are forced through specially designed dies to create complex profiles with precise dimensions and structural integrity. The main functions of aluminum door and window manufacturing encompass structural framing, weather sealing, thermal performance optimization, and aesthetic enhancement of building envelopes. Modern aluminum door and window manufacturing facilities employ computer-controlled cutting systems, automated welding stations, and sophisticated finishing processes to ensure consistent product quality and dimensional accuracy. Technological features include thermal break technology, where polyamide strips interrupt heat transfer through aluminum frames, significantly improving energy efficiency ratings. Advanced powder coating systems apply durable finishes that resist fading, chalking, and corrosion while offering extensive color customization options. Quality control measures throughout aluminum door and window manufacturing include rigorous testing protocols for air infiltration, water penetration, structural load capacity, and thermal performance according to industry standards such as AAMA and NFRC certifications. Applications span residential replacement windows, commercial curtain wall systems, storefront installations, sliding patio doors, casement windows, and specialized architectural glazing solutions. The aluminum door and window manufacturing industry serves diverse market segments including single-family homes, multi-story residential complexes, office buildings, retail establishments, healthcare facilities, and educational institutions, providing versatile solutions that balance functionality, durability, and architectural design requirements.