best energyefficient thermal break aluminum doors and windows

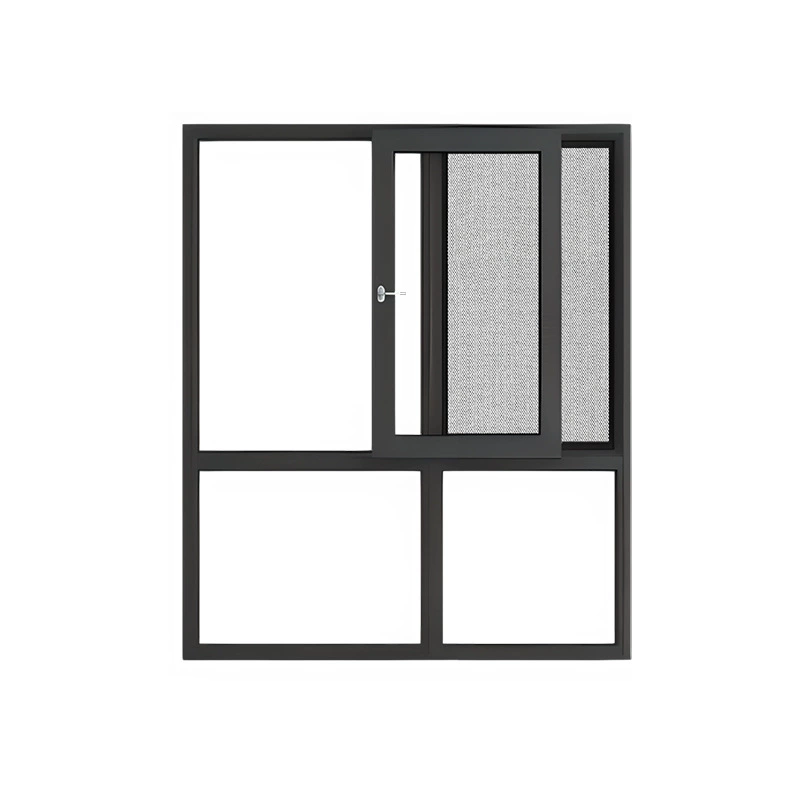

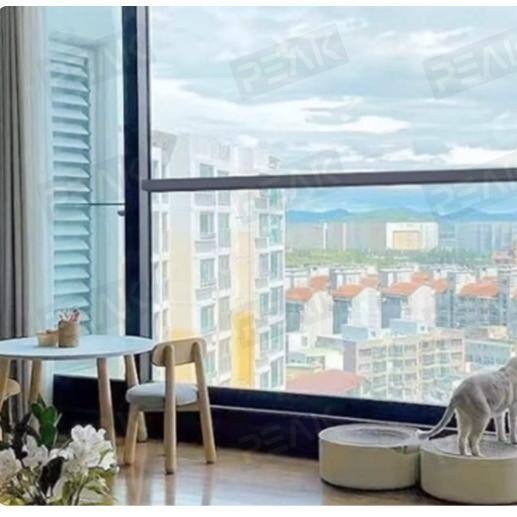

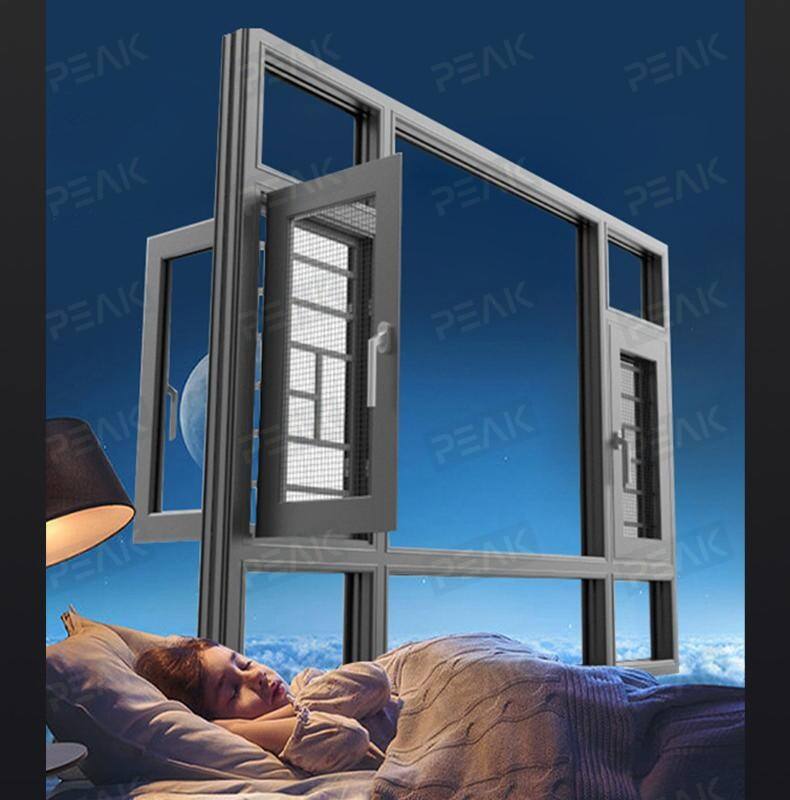

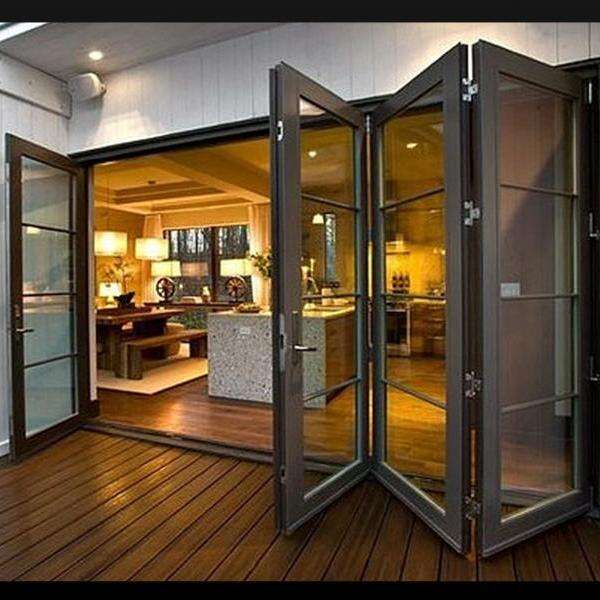

The best energy-efficient thermal break aluminum doors and windows represent a revolutionary advancement in modern building technology, combining superior performance with environmental sustainability. These innovative architectural solutions utilize cutting-edge thermal barrier technology to create an effective separation between interior and exterior aluminum components, dramatically reducing heat transfer and energy loss. At their core, these systems feature polyamide strips or thermal breaks that interrupt the continuous aluminum frame, preventing thermal bridging that traditionally occurs in standard aluminum fenestration products. The main functions of the best energy-efficient thermal break aluminum doors and windows extend beyond basic weather protection to include exceptional thermal insulation, condensation control, noise reduction, and structural integrity. The technological features incorporate multi-chambered profiles with precision-engineered thermal barriers, high-performance glazing systems, and advanced weatherstripping components that work synergistically to achieve outstanding energy ratings. These systems typically feature low U-values, indicating superior insulating properties, while maintaining the strength and durability that aluminum is renowned for. Applications span across residential, commercial, and industrial sectors, making them ideal for luxury homes, office buildings, schools, hospitals, and retail establishments where energy efficiency and comfort are paramount. The versatility of the best energy-efficient thermal break aluminum doors and windows allows for custom configurations including casement windows, sliding doors, tilt-and-turn systems, and large-format glazing solutions. Manufacturing processes involve precision extrusion techniques that create complex profiles with integrated thermal barriers, followed by careful assembly procedures that ensure optimal performance. Quality control measures throughout production guarantee consistent thermal performance, structural integrity, and aesthetic appeal that meets rigorous international standards for energy efficiency and building performance.