Customization and Design Flexibility Solutions

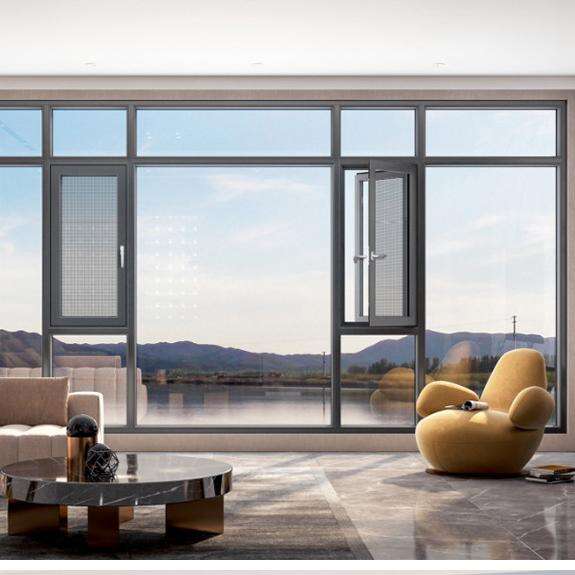

Leading energy efficient thermal break aluminum doors and windows supplier organizations excel in providing extensive customization and design flexibility solutions that accommodate diverse architectural requirements and aesthetic preferences across residential, commercial, and institutional market segments. These suppliers maintain comprehensive design capabilities that enable architects and specifiers to realize their vision without compromising thermal performance or structural integrity. Custom color matching services utilize advanced spectrophotometry to reproduce virtually any desired finish, from standard architectural colors to unique brand-specific hues that maintain consistency across large building projects. The energy efficient thermal break aluminum doors and windows supplier offers multiple surface treatment options including powder coating, anodizing, and specialized coatings that provide enhanced durability and weather resistance while maintaining aesthetic appeal. Profile customization capabilities extend beyond standard dimensions to include specialized shapes and configurations that address unique architectural challenges such as curved facades, irregular openings, and historical restoration requirements. Advanced fabrication equipment enables precision modification of standard profiles to create custom mullion patterns, decorative elements, and functional features that enhance both appearance and performance. Hardware integration options encompass multiple operating mechanisms including casement, awning, sliding, and tilt-turn configurations that accommodate specific functional requirements and user preferences. The energy efficient thermal break aluminum doors and windows supplier collaborates with hardware manufacturers to ensure seamless integration of high-performance locking systems, operators, and accessories that complement the thermal efficiency goals of the overall system. Glass specification flexibility allows optimization for specific climate conditions and performance requirements through various glazing options including Low-E coatings, tinted glass, laminated assemblies, and specialty glass products for security or acoustic applications. Project management services coordinate complex installations involving multiple building phases and trades, ensuring proper sequencing and quality control throughout the construction process. Technical support extends from initial design consultation through post-installation service, providing expertise that maximizes system performance and customer satisfaction. Value engineering services help optimize specifications to achieve required performance levels while managing project budgets effectively.