best thermal break aluminum doors and windows manufacturer

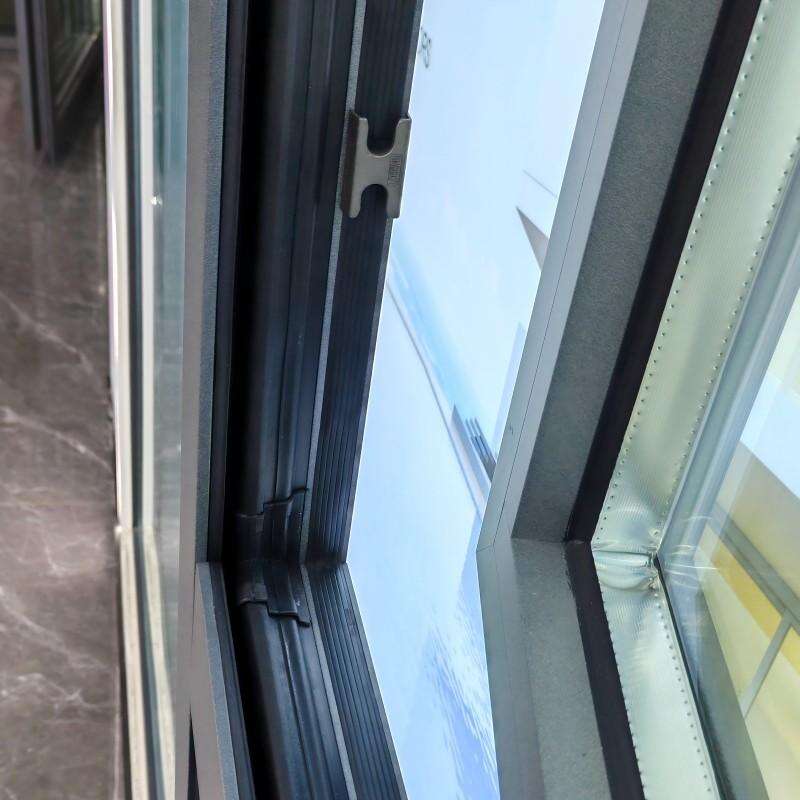

The best thermal break aluminum doors and windows manufacturer represents the pinnacle of modern fenestration technology, combining superior materials engineering with advanced manufacturing processes to deliver exceptional performance solutions. These specialized manufacturers focus on creating energy-efficient products that address contemporary building requirements while maintaining aesthetic appeal and structural integrity. Thermal break technology forms the cornerstone of their product development, utilizing polyamide strips or other insulating materials to interrupt heat transfer through aluminum frames. This innovative approach transforms traditional aluminum windows and doors into high-performance building components that significantly reduce energy consumption and enhance occupant comfort. Leading manufacturers in this sector invest heavily in research and development to continuously improve their thermal break systems, ensuring optimal insulation values and condensation resistance. The manufacturing process involves precision engineering where aluminum profiles are carefully designed with dedicated channels for thermal break insertion. Advanced extrusion techniques create complex geometries that accommodate multiple weather seals, hardware systems, and glazing options while maintaining structural strength. Quality control measures include rigorous testing protocols that evaluate thermal performance, air infiltration resistance, water penetration resistance, and structural loading capabilities. The best thermal break aluminum doors and windows manufacturer typically offers comprehensive product ranges including casement windows, sliding systems, tilt-turn configurations, entrance doors, patio doors, and curtain wall systems. These products find applications across residential, commercial, and institutional construction projects where energy efficiency, durability, and design flexibility are paramount. Manufacturing facilities often feature state-of-the-art equipment including CNC machining centers, automated cutting systems, and precision assembly lines that ensure consistent quality and dimensional accuracy. The integration of smart manufacturing technologies enables these companies to provide customized solutions while maintaining competitive production timelines and cost structures.