Customizable Design Solutions with Professional Installation Support

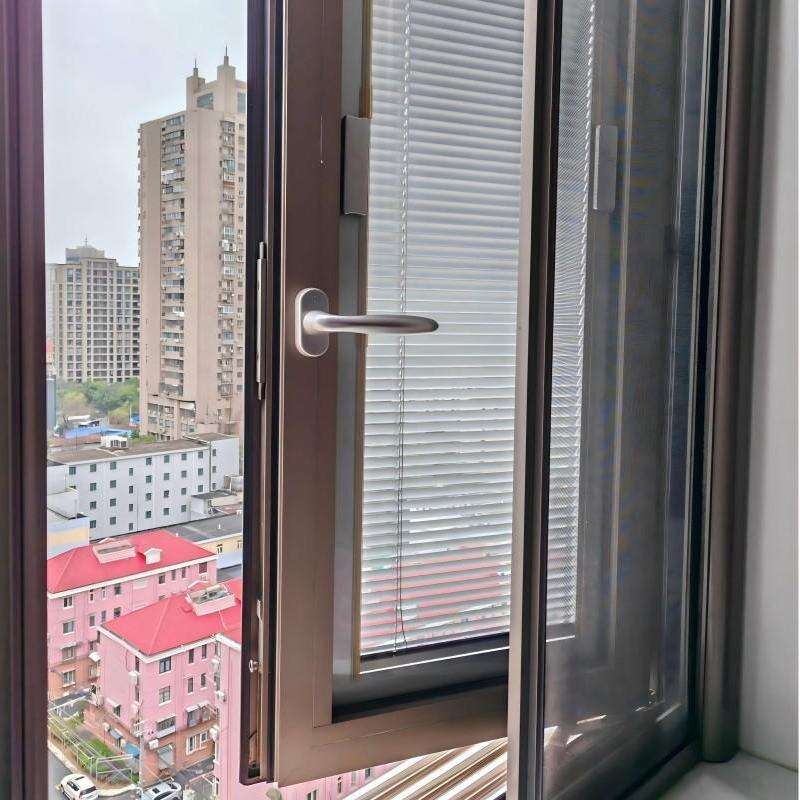

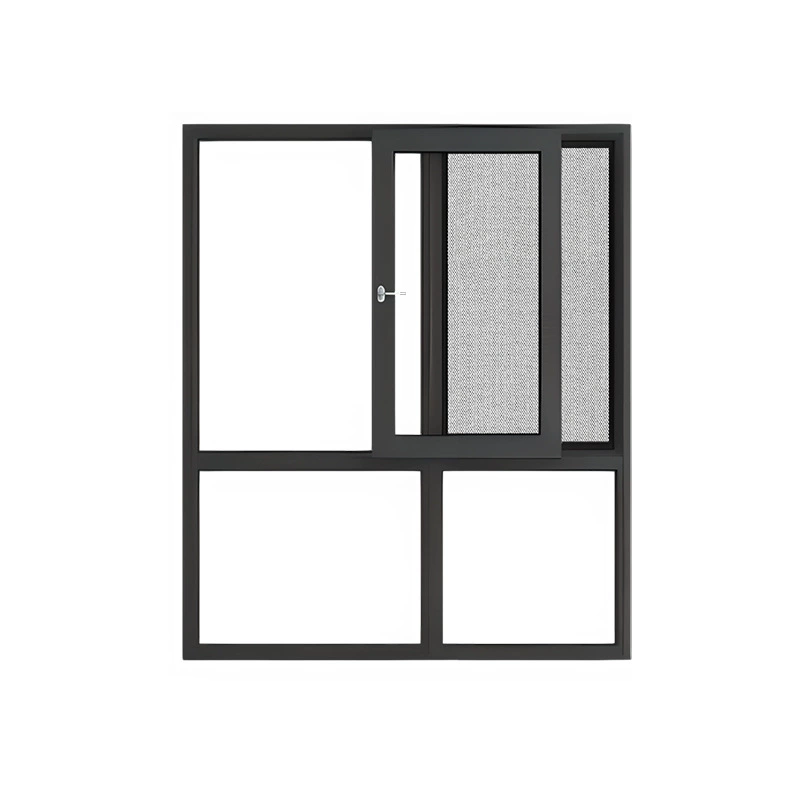

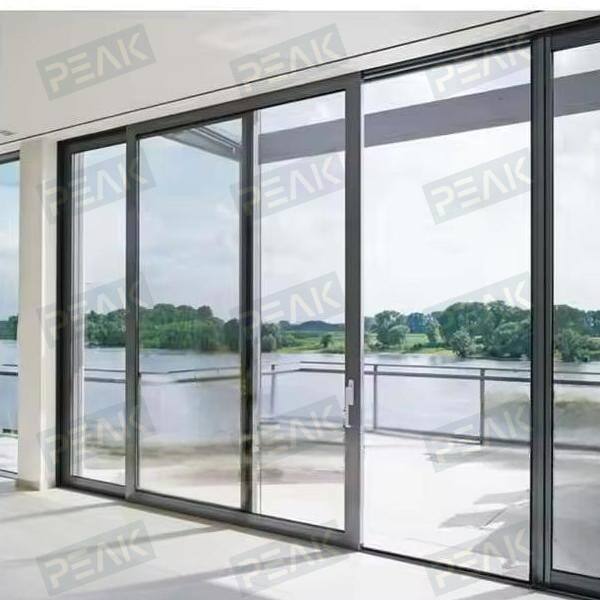

Design flexibility represents a crucial advantage offered by leading thermal break aluminum doors and windows manufacturer operations, providing architects, contractors, and property owners with extensive customization options that accommodate diverse aesthetic preferences and functional requirements without compromising thermal performance or structural integrity. Color selection includes comprehensive ranges of standard finishes along with custom color matching capabilities that ensure perfect coordination with existing architectural elements or specific design themes. Powder coating processes deliver uniform, durable finishes that maintain their appearance throughout extended exposure to UV radiation, weather conditions, and normal wear patterns. Anodizing options provide alternative surface treatments that enhance corrosion resistance while offering distinctive metallic appearances that complement contemporary architectural styles. Hardware selection encompasses various styles, finishes, and operational mechanisms that allow customization of both functionality and aesthetic appeal. Handle designs range from contemporary minimalist options to traditional styles that complement historical architectural themes, while locking mechanisms provide security levels appropriate for specific applications. Glazing options include single, double, and triple-pane configurations with various glass types including low-emissivity coatings, laminated safety glass, and specialized performance glazing that enhances energy efficiency, security, or acoustic properties. Frame profiles accommodate different glazing thicknesses while maintaining thermal break effectiveness and structural performance. Configuration flexibility allows creation of custom sizes, shapes, and operational styles including fixed panels, casement windows, sliding systems, and specialty shapes that match unique architectural requirements. Engineering support services include structural calculations, thermal performance modeling, and installation guidance that ensure custom solutions meet building codes and performance specifications. Professional installation support distinguishes leading manufacturers through comprehensive training programs, technical documentation, and field support services that ensure proper installation techniques maximize product performance. Installation teams receive ongoing education about evolving best practices, new products, and troubleshooting procedures that maintain installation quality standards. Warranty programs provide long-term protection for both products and installation workmanship, demonstrating manufacturer confidence in their systems while providing property owners with security regarding their investments. The combination of design flexibility and professional support creates value through solutions that meet specific project requirements while delivering reliable performance and aesthetic satisfaction that enhances property value and occupant satisfaction.