casement sliding thermal break aluminum doors and windows manufacturer

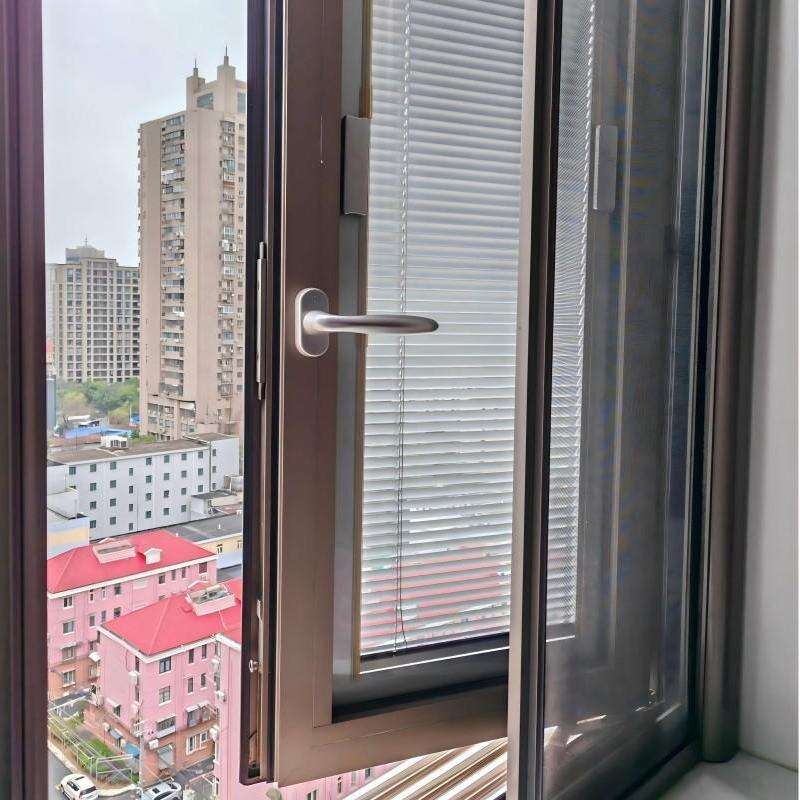

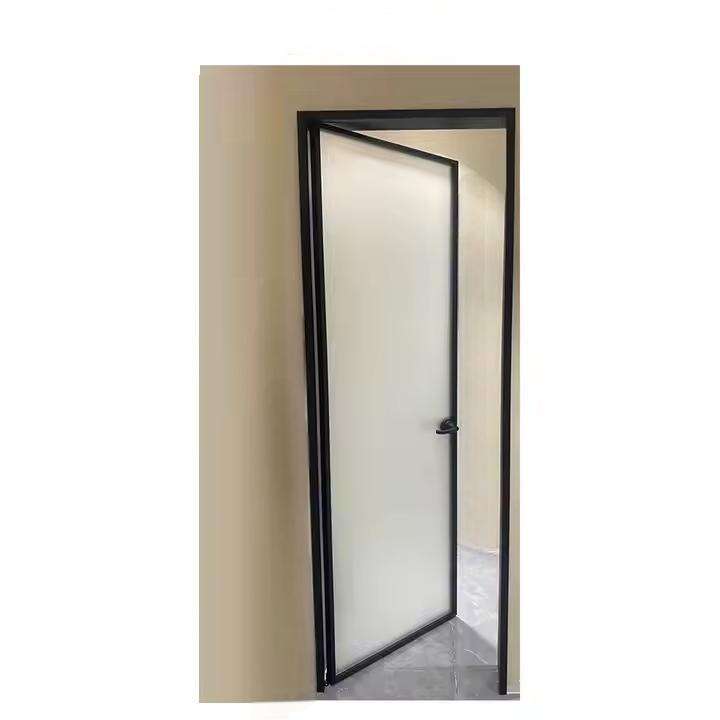

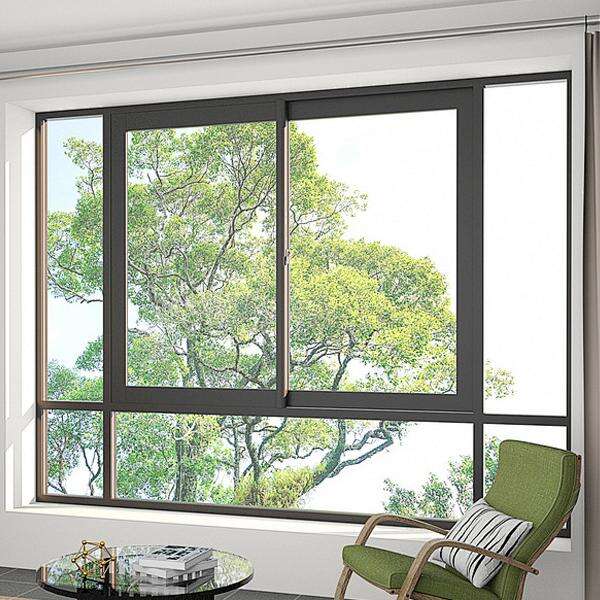

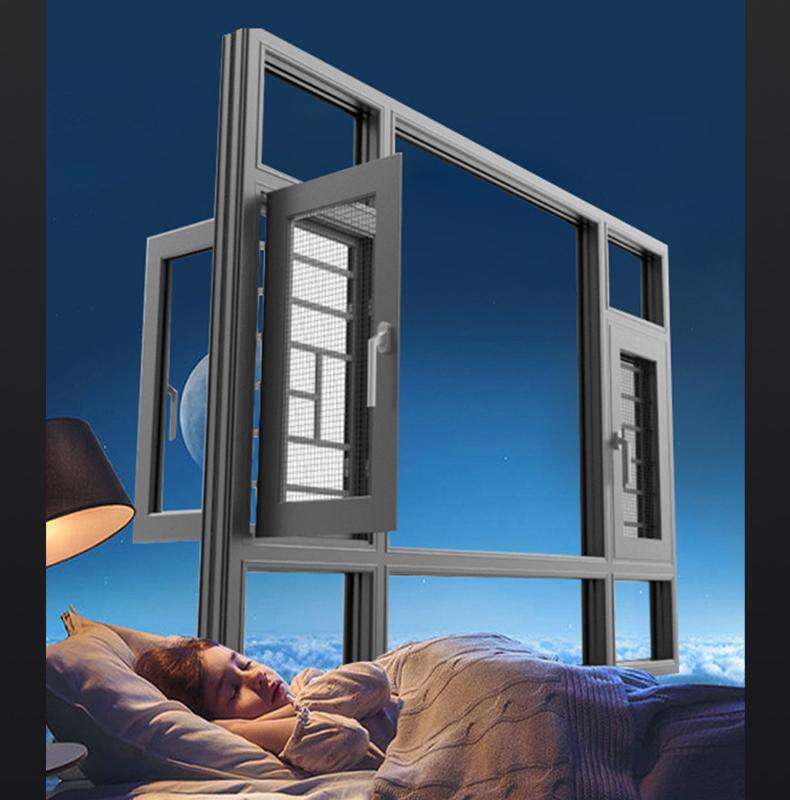

A casement sliding thermal break aluminum doors and windows manufacturer specializes in producing advanced fenestration systems that combine superior thermal performance with contemporary design aesthetics. These manufacturers focus on creating innovative door and window solutions that feature polyamide thermal barriers strategically placed between inner and outer aluminum profiles to prevent heat transfer. The primary function of these systems involves providing exceptional insulation while maintaining the structural integrity and visual appeal that aluminum construction offers. Modern casement sliding thermal break aluminum doors and windows manufacturer facilities utilize state-of-the-art production techniques including precision extrusion processes, automated assembly lines, and rigorous quality control protocols. The technological features encompass multi-chamber profile designs that enhance thermal efficiency, precision-engineered hardware systems for smooth operation, and advanced glazing options that maximize energy performance. These manufacturers typically incorporate weather sealing technologies, corrosion-resistant surface treatments, and customizable powder coating finishes to meet diverse architectural requirements. Applications span residential construction projects, commercial building developments, institutional facilities, and renovation markets where energy efficiency regulations demand superior thermal performance. The casement sliding thermal break aluminum doors and windows manufacturer serves architects, contractors, builders, and homeowners seeking sustainable building solutions that reduce energy consumption while delivering long-term durability. Manufacturing capabilities often include custom sizing options, specialized hardware configurations, and integration with smart building technologies. Quality assurance processes ensure compliance with international standards for thermal performance, structural integrity, and operational reliability, making these manufacturers essential partners in contemporary construction projects prioritizing environmental sustainability and occupant comfort.