casementsliding thermal break aluminum doors and windows vendors

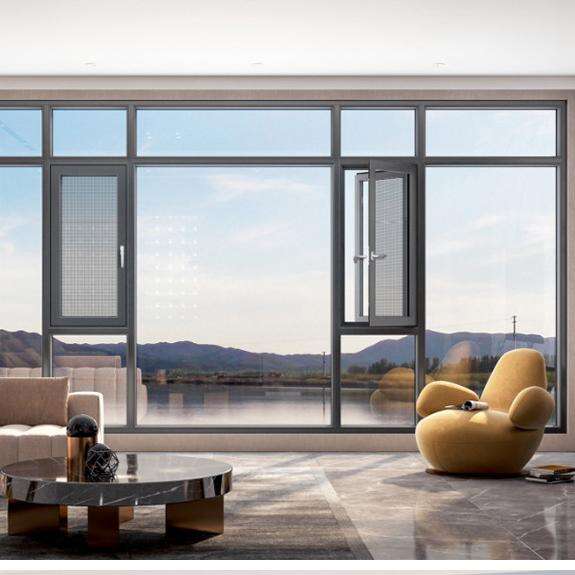

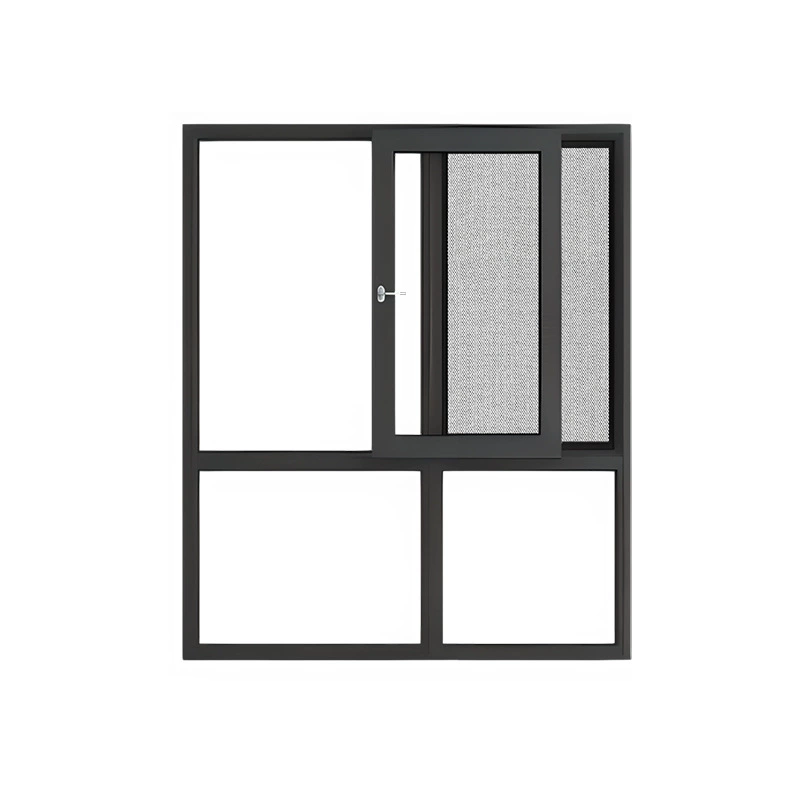

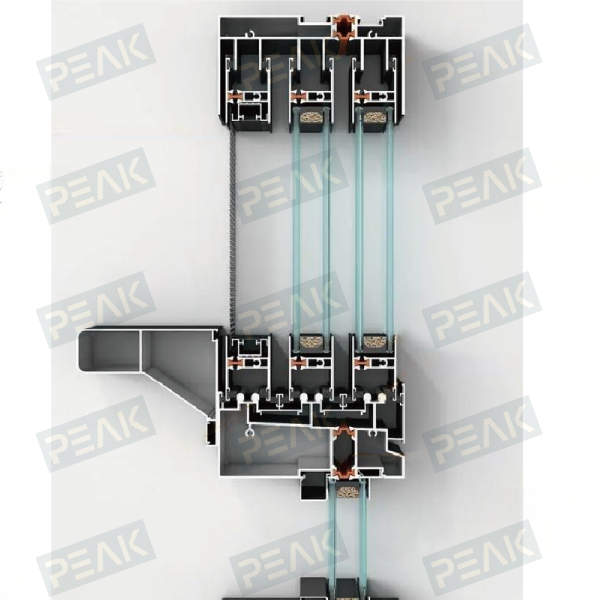

Casementsliding thermal break aluminum doors and windows vendors represent a specialized segment of the construction industry, providing advanced fenestration solutions that combine multiple operational mechanisms with superior energy efficiency. These vendors manufacture and distribute hybrid window and door systems that integrate both casement and sliding functionalities within a single frame structure, utilizing thermal break technology to minimize heat transfer and maximize insulation performance. The thermal break aluminum construction involves inserting non-conductive materials between interior and exterior aluminum components, creating a barrier that prevents thermal bridging and significantly reduces energy loss. Casementsliding thermal break aluminum doors and windows vendors serve residential, commercial, and industrial markets by offering versatile opening configurations that accommodate diverse architectural requirements and space constraints. The main functions of these systems include providing natural ventilation through multiple opening modes, ensuring weather protection through precision-engineered sealing mechanisms, and delivering exceptional thermal performance through advanced material technology. Technological features encompass multi-point locking systems for enhanced security, corrosion-resistant aluminum alloy construction for longevity, integrated drainage systems for moisture management, and precision-machined hardware components for smooth operation. The thermal break technology specifically involves polyamide strips or similar insulating materials that create a discontinuous thermal path, preventing exterior temperature fluctuations from affecting interior climate conditions. Applications span across various building types including luxury residences, office complexes, educational institutions, healthcare facilities, and hospitality venues where both aesthetic appeal and functional performance are paramount. These vendors typically offer customization services to meet specific project requirements, including various color options, glass configurations, and hardware selections. The casementsliding thermal break aluminum doors and windows vendors market continues expanding as building codes increasingly emphasize energy efficiency and sustainable construction practices. Installation services, warranty programs, and technical support are commonly provided by established vendors to ensure optimal system performance and customer satisfaction throughout the product lifecycle.