Customization Capabilities and Design Flexibility Leadership

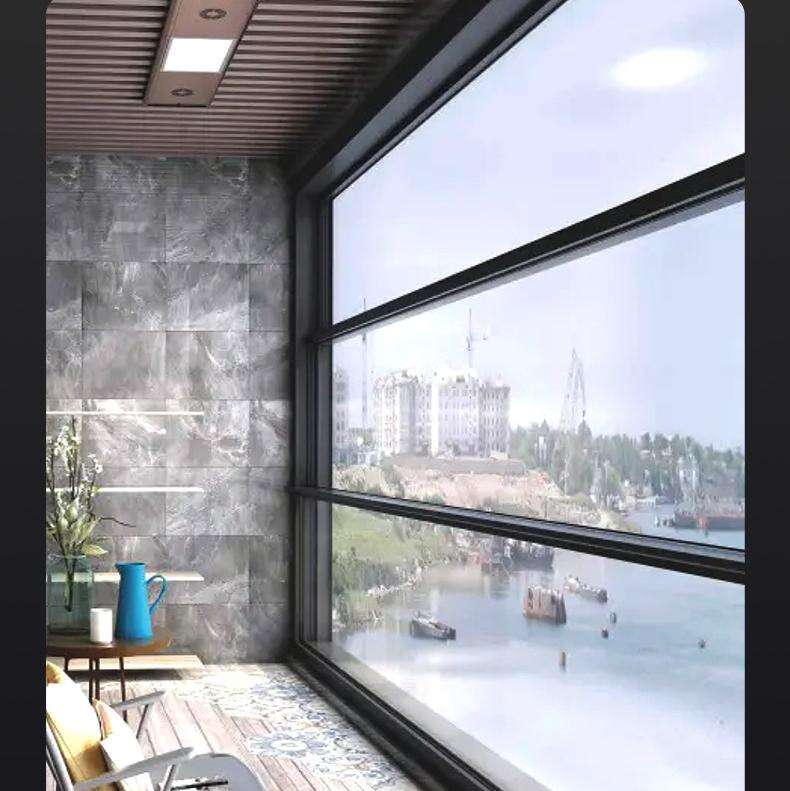

The casementsliding thermal break aluminum doors and windows factory excels in providing extensive customization options that enable architects, builders, and homeowners to achieve their exact vision while maintaining superior performance standards. Advanced design software and flexible manufacturing systems allow for unlimited size configurations, accommodating everything from standard residential openings to expansive commercial curtain wall applications with seamless integration. The factory's engineering team collaborates closely with customers to develop custom profiles, hardware selections, and glazing specifications that meet specific project requirements while optimizing structural performance and energy efficiency. Color customization capabilities extend far beyond standard offerings, with powder coating facilities that can match virtually any architectural specification using RAL, AAMA, or custom color formulations that maintain durability and fade resistance over decades of exposure. The casementsliding thermal break aluminum doors and windows factory engineering department provides comprehensive design support, including structural calculations, thermal modeling, and performance predictions that ensure custom solutions meet all building code requirements and project specifications. Specialized tooling capabilities enable the production of unique profile shapes and configurations that accommodate unusual architectural details, historic preservation requirements, or innovative design concepts that push conventional boundaries. The manufacturing flexibility extends to hardware integration, with the ability to incorporate specialized locking mechanisms, automated operators, smart home connectivity, and security features that enhance functionality and user experience. Glazing options encompass an extensive range of high-performance glass types, including low-E coatings, laminated safety glass, decorative patterns, and smart glass technologies that respond to environmental conditions or user preferences. The casementsliding thermal break aluminum doors and windows factory maintains relationships with leading component suppliers worldwide, ensuring access to the latest innovations in seals, hardware, and glazing materials that can be integrated into custom solutions. Project management services coordinate complex installations, providing technical support, sequenced delivery schedules, and on-site assistance that ensures successful completion of demanding architectural projects. The design flexibility includes structural glazing options, curtain wall integration capabilities, and specialized mounting systems that accommodate unique construction methods or retrofit applications. Quality assurance procedures for custom products include prototype testing, first article inspection, and ongoing production monitoring that maintains consistency even for small-batch specialty items. The casementsliding thermal break aluminum doors and windows factory commitment to customization excellence enables customers to achieve distinctive architectural visions while benefiting from proven manufacturing expertise and quality standards.