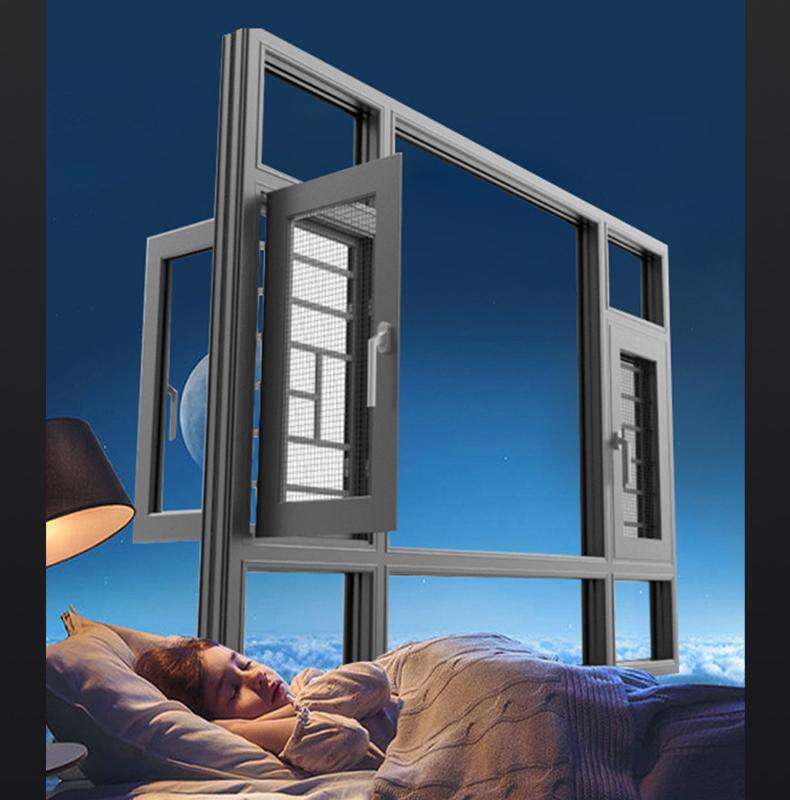

Versatile Dual Operation System for Enhanced Functionality

The innovative dual operation capability of popular casementsliding thermal break aluminum doors and windows provides unprecedented flexibility in ventilation control and space management, addressing diverse architectural requirements and user preferences within a single integrated system. The casement function allows the window or door panel to swing outward on precision-engineered hinges, creating a wide opening that maximizes natural ventilation flow and provides unobstructed views. This outward swing design offers several practical advantages including easier cleaning of exterior glass surfaces, improved emergency egress capabilities, and enhanced weather protection as the panel naturally deflects rain away from the opening. The sliding mechanism operates on heavy-duty track systems with ball bearing rollers or precision linear guides that ensure smooth, effortless movement even with large, heavy panels. This sliding functionality proves invaluable in situations where exterior clearance is limited, such as balconies, patios, or areas adjacent to walkways where outward-swinging panels might create obstacles or safety concerns. The dual operation system allows users to adapt the window or door function to changing needs throughout different seasons or times of day, optimizing ventilation patterns and space utilization. Engineering challenges overcome in developing this dual functionality include maintaining proper sealing integrity across both operation modes, ensuring consistent security performance, and preserving aesthetic continuity regardless of operational configuration. The hardware systems supporting both functions undergo rigorous testing to verify smooth operation, longevity, and resistance to wear under repeated use cycles. Popular casementsliding thermal break aluminum doors and windows incorporate advanced locking mechanisms that secure the unit effectively in both casement and sliding positions, maintaining security integrity across all operational modes. The versatility extends to installation applications where single units can serve multiple functions based on specific room layouts or changing architectural requirements over time.