casementsliding thermal break aluminum doors and windows supplier

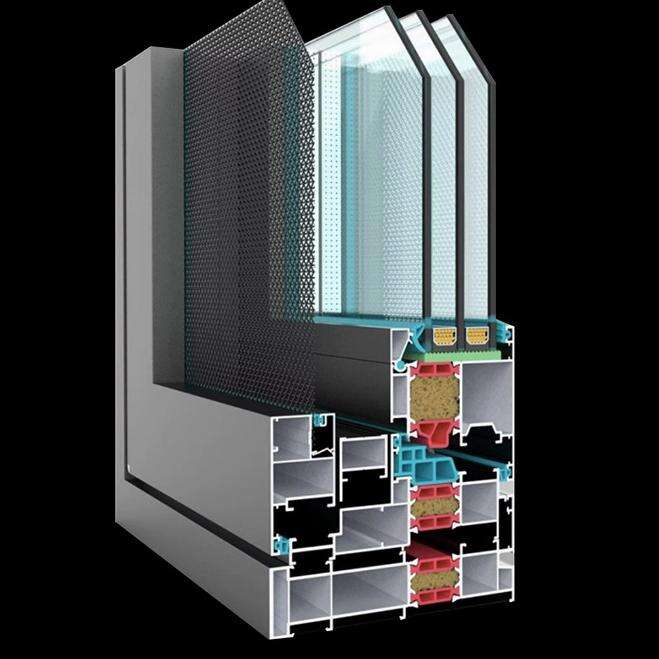

A casementsliding thermal break aluminum doors and windows supplier represents a specialized manufacturer that combines innovative engineering with premium materials to deliver energy-efficient building solutions. These suppliers focus on creating advanced aluminum door and window systems that feature thermal break technology, which effectively separates the interior and exterior aluminum components to minimize heat transfer. The thermal break barrier, typically made from polyamide strips, creates an insulation zone that dramatically reduces thermal conductivity while maintaining structural integrity. Modern casementsliding thermal break aluminum doors and windows supplier operations utilize state-of-the-art manufacturing processes, including precision cutting, welding, and assembly techniques that ensure consistent quality and performance. The main functions of these systems include providing superior insulation, weather resistance, security, and aesthetic appeal for residential and commercial buildings. The casement design allows for full opening capabilities, maximizing ventilation and emergency egress options. Meanwhile, the sliding functionality offers space-saving solutions ideal for areas with limited clearance. Technological features encompass multi-point locking systems, weatherstripping seals, drainage channels, and reinforced corner connections. These suppliers typically offer customization options including various colors, finishes, hardware selections, and glazing configurations to meet specific architectural requirements. Applications span across residential homes, commercial buildings, educational facilities, healthcare centers, and industrial structures. The aluminum construction provides excellent durability, corrosion resistance, and low maintenance requirements compared to traditional materials. Many casementsliding thermal break aluminum doors and windows supplier companies also provide comprehensive services including consultation, measurement, installation, and after-sales support to ensure optimal performance and customer satisfaction throughout the product lifecycle.