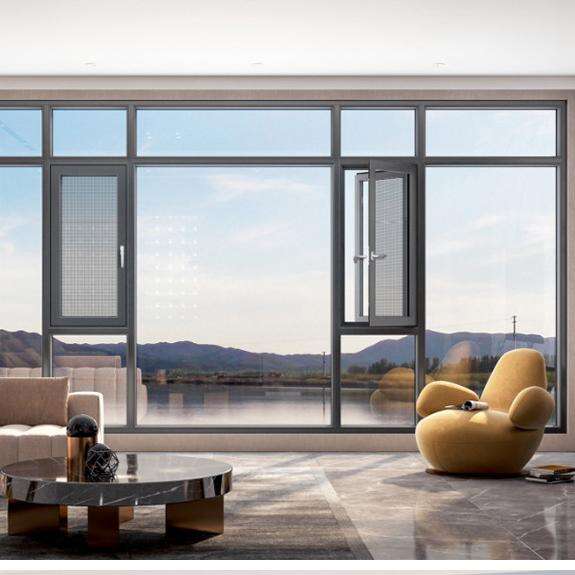

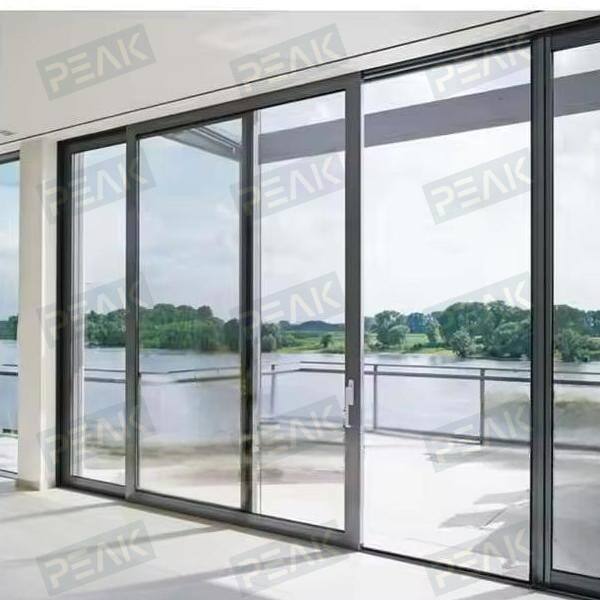

quality energyefficient thermal break aluminum doors and windows

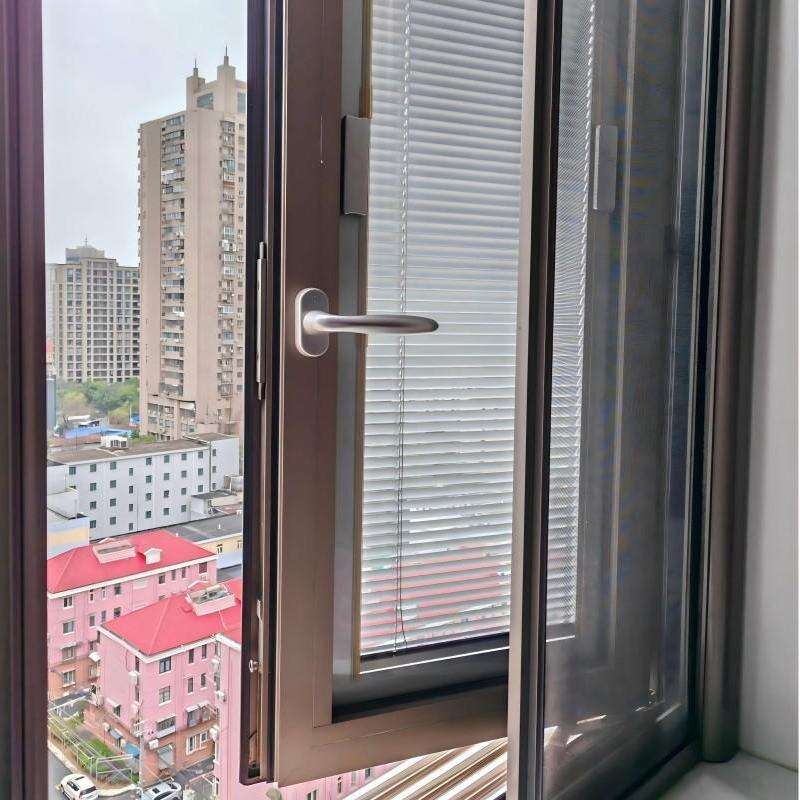

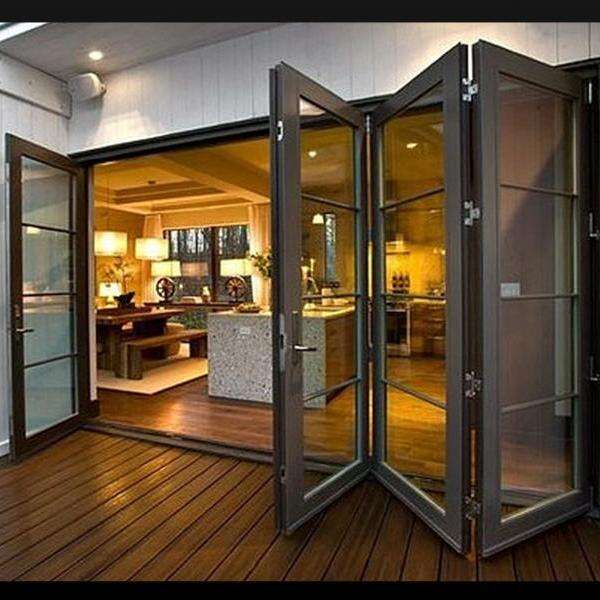

Quality energy-efficient thermal break aluminum doors and windows represent a revolutionary advancement in building construction technology, combining superior insulation properties with exceptional durability and aesthetic appeal. These innovative systems feature a specialized thermal barrier that effectively separates the interior and exterior aluminum frames, dramatically reducing heat transfer and creating optimal indoor climate control. The thermal break technology incorporates polyamide strips or foam materials positioned between aluminum sections, creating an insulating bridge that prevents thermal conductivity while maintaining structural integrity. This design ensures that quality energy-efficient thermal break aluminum doors and windows deliver outstanding performance across diverse climate conditions. The main functions of these systems include thermal insulation, sound dampening, weather resistance, and enhanced security features. Advanced manufacturing processes ensure precise engineering tolerances, creating seamless integration between frame components and glazing systems. Multi-point locking mechanisms provide superior security while maintaining smooth operation throughout extended use cycles. Quality energy-efficient thermal break aluminum doors and windows incorporate advanced weatherstripping technologies that create airtight seals, preventing moisture infiltration and draft penetration. The aluminum construction offers exceptional resistance to corrosion, warping, and dimensional changes, ensuring long-term performance reliability. These systems accommodate various glazing options, including double and triple-pane configurations with specialized coatings for enhanced thermal performance. Applications span residential, commercial, and institutional projects where energy efficiency and performance are paramount. Quality energy-efficient thermal break aluminum doors and windows find extensive use in modern architectural designs, sustainable building projects, and retrofit applications. The versatility of these systems allows customization for specific project requirements, including various opening configurations, hardware options, and finish selections to complement diverse architectural styles.