highrise building thermal break aluminum doors and windows vendors

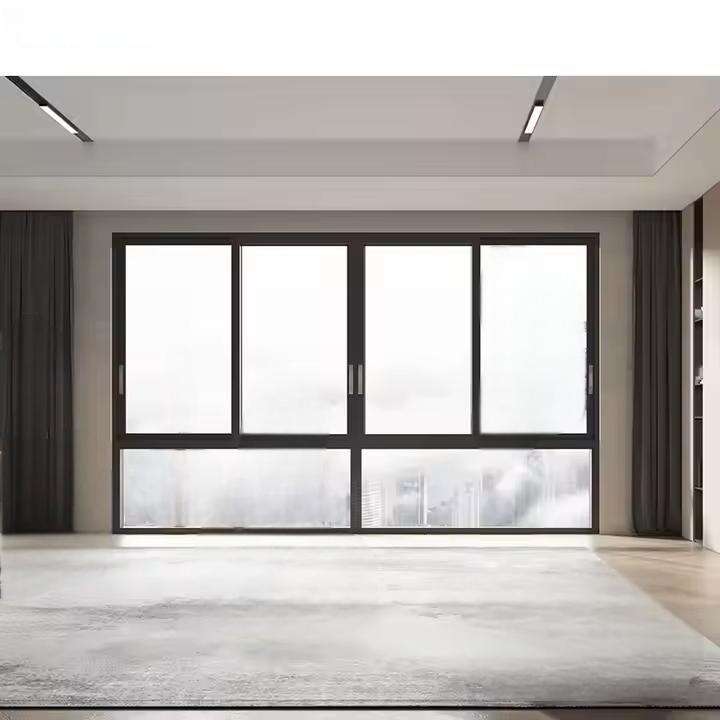

Highrise building thermal break aluminum doors and windows vendors represent a specialized segment of the construction industry that focuses on providing energy-efficient fenestration solutions for tall commercial and residential structures. These vendors manufacture and supply advanced aluminum window and door systems specifically engineered to meet the demanding requirements of skyscrapers, office towers, and high-rise residential complexes. The thermal break technology incorporated into these products involves inserting non-conductive materials between the interior and exterior aluminum frames, effectively interrupting the heat transfer path and significantly improving energy performance. Modern highrise building thermal break aluminum doors and windows vendors utilize sophisticated manufacturing processes that combine lightweight aluminum profiles with polyamide thermal barriers, creating systems that deliver exceptional structural integrity while maintaining superior insulation properties. These specialized vendors understand the unique challenges faced by tall buildings, including wind loads, thermal expansion, water penetration resistance, and acoustic performance requirements. Their product portfolios typically encompass curtain wall systems, ribbon windows, casement windows, sliding doors, and custom architectural solutions designed to complement contemporary building aesthetics. The technological features of products from leading highrise building thermal break aluminum doors and windows vendors include multi-chamber frame designs, advanced glazing compatibility, precision-engineered hardware systems, and comprehensive weather sealing mechanisms. These vendors often collaborate closely with architects, engineers, and contractors to develop customized solutions that meet specific project requirements while adhering to international building codes and energy efficiency standards. The applications for these products extend beyond traditional commercial towers to include mixed-use developments, luxury residential high-rises, institutional buildings, and specialized structures such as hospitals and educational facilities where energy efficiency and occupant comfort are paramount considerations.