Customization Capabilities and Design Flexibility

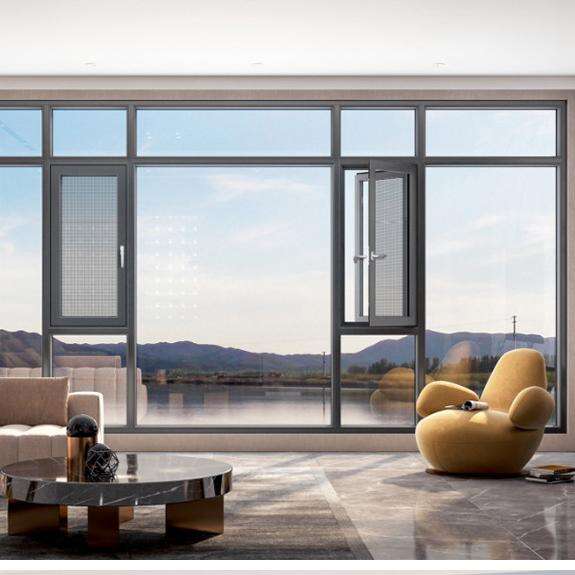

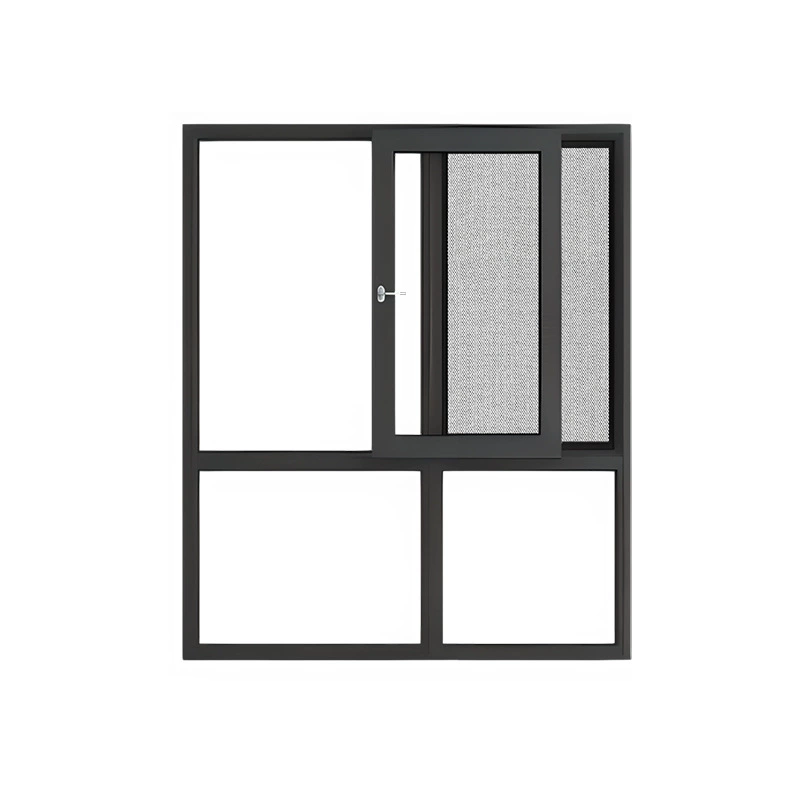

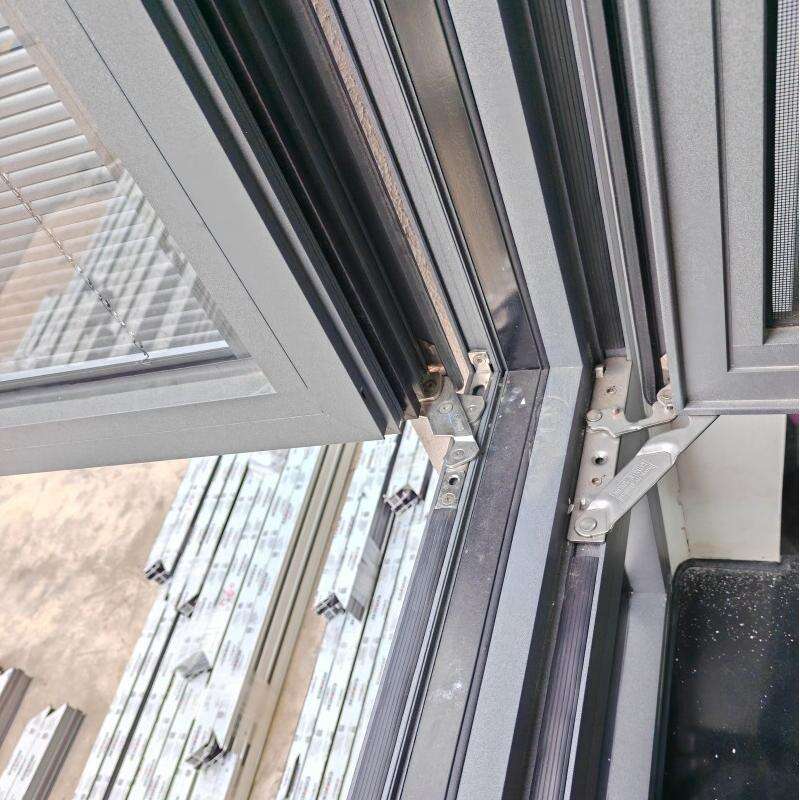

The distinctive advantage of partnering with an established villa thermal break aluminum doors and windows factory lies in the extensive customization capabilities and design flexibility that enable architects and homeowners to realize their unique architectural visions while maintaining superior thermal performance standards. Professional manufacturing facilities maintain comprehensive libraries of aluminum profiles in various depths, configurations, and structural designs that accommodate diverse architectural styles ranging from contemporary minimalist aesthetics to traditional classical proportions. Color customization options extend far beyond standard offerings through advanced powder coating systems capable of producing virtually any desired finish including metallic effects, textured surfaces, wood grain simulations, and custom color matches that coordinate perfectly with existing architectural elements. Glazing options represent another dimension of customization flexibility, with professional villa thermal break aluminum doors and windows factory operations offering single, double, and triple glazing configurations utilizing low-emissivity coatings, argon gas fills, warm edge spacers, and specialized glass types including laminated safety glass, tempered security glass, and decorative options featuring etching, frosting, or embedded patterns. Hardware selection encompasses a vast array of handle styles, locking mechanisms, hinge configurations, and operational systems including casement, sliding, folding, and tilt-and-turn configurations that optimize functionality for specific applications and user preferences. Dimensional flexibility allows for the creation of oversized openings, complex geometric shapes, and integrated systems that combine multiple operating styles within single installations. Professional manufacturing capabilities include the integration of smart home technology features such as motorized operators, integrated sensors, and connectivity systems that enable remote monitoring and control through smartphone applications. The design development process typically involves collaborative consultation services where factory technical specialists work directly with architects and contractors to optimize system specifications, resolve installation challenges, and ensure seamless integration with overall building designs. Custom fabrication capabilities extend to specialized applications including curved profiles, angled installations, and complex multi-panel configurations that would be impossible to achieve with standard off-the-shelf products, ensuring that even the most challenging architectural concepts can be successfully realized while maintaining the superior thermal performance characteristics that define quality villa thermal break aluminum doors and windows factory products.