Superior Weather Protection and Structural Durability

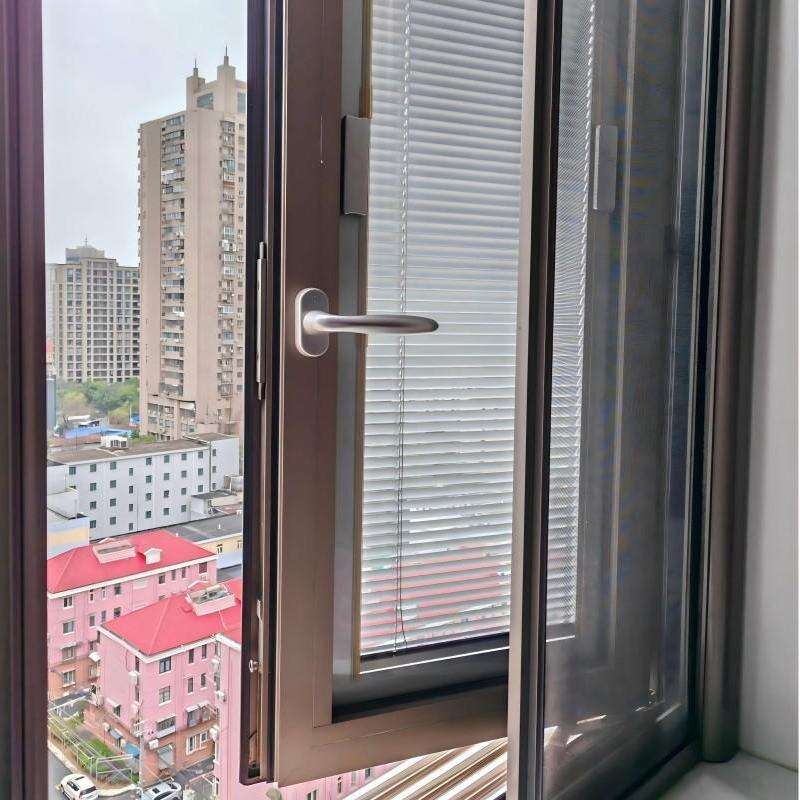

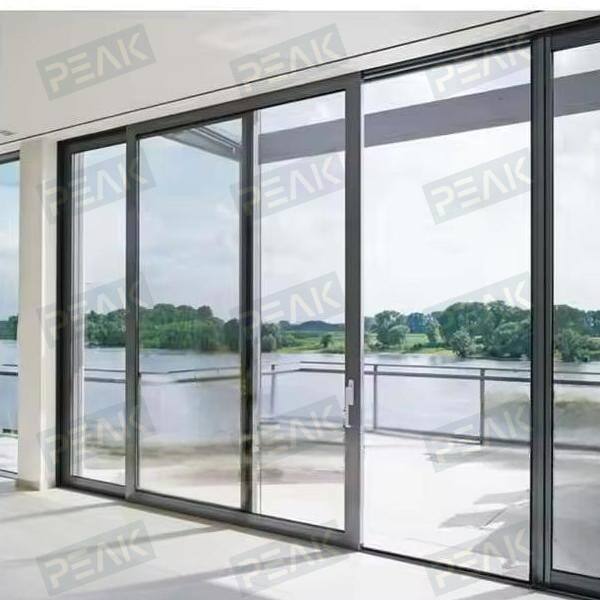

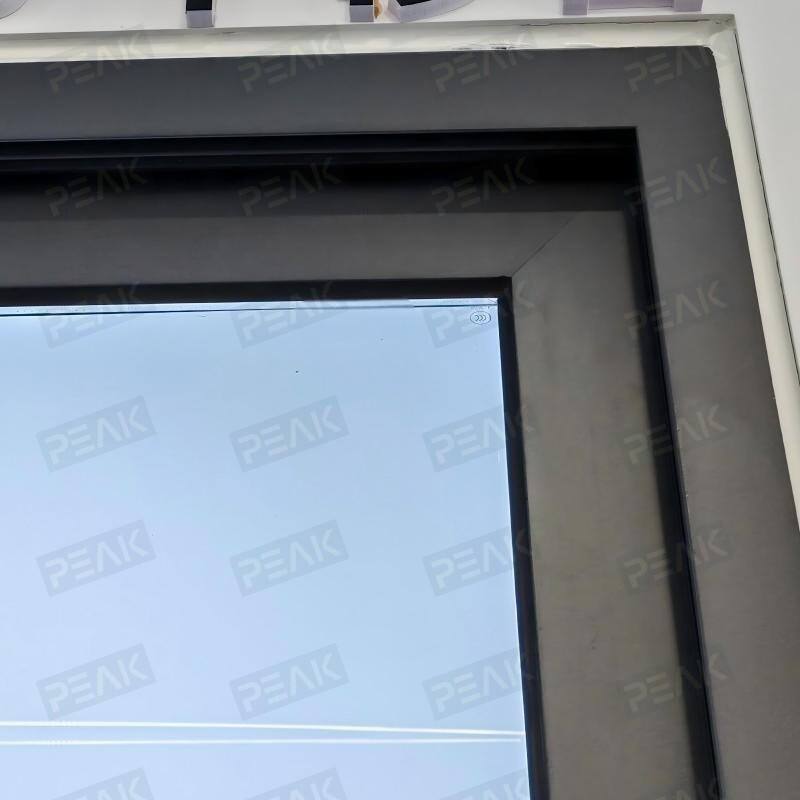

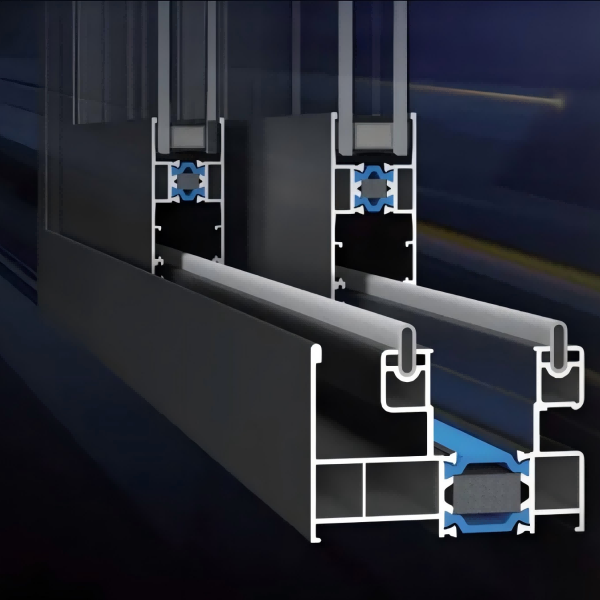

Villa thermal break aluminum doors excel in providing comprehensive weather protection through their advanced sealing systems and robust structural design that withstands extreme environmental conditions. The weather sealing technology incorporates multiple layers of EPDM gaskets and weatherstripping that create a continuous barrier against water infiltration, air leakage, and dust penetration. These sealing systems are strategically positioned at all potential entry points, including the threshold, jambs, and head of the door frame, ensuring complete perimeter protection. The gasket materials are specially formulated to maintain flexibility and effectiveness across temperature ranges from -40°C to +80°C, ensuring reliable performance in diverse climatic conditions. Villa thermal break aluminum doors undergo rigorous testing procedures including water penetration tests, air infiltration assessments, and structural load evaluations to verify their weather resistance capabilities. The aluminum alloy construction provides inherent corrosion resistance, eliminating concerns about rust formation that commonly affects steel door systems in coastal or high-humidity environments. The marine-grade aluminum profiles maintain structural integrity and aesthetic appearance for decades without requiring extensive maintenance or protective treatments. Impact resistance testing demonstrates that villa thermal break aluminum doors can withstand significant force loads without compromising their sealing performance or structural stability. The reinforced frame construction distributes loads evenly across the entire structure, preventing localized stress concentrations that could lead to failure points. Hurricane testing certifications validate the ability of these doors to withstand extreme wind loads and debris impact, making them ideal for properties in storm-prone regions. The drainage system integrated into villa thermal break aluminum doors efficiently channels water away from critical sealing areas, preventing standing water that could compromise long-term performance. Advanced surface treatments including powder coating and anodizing provide additional protection against UV radiation, salt spray, and chemical exposure, ensuring lasting beauty and functionality throughout the service life.