aluminum door window manufacturing

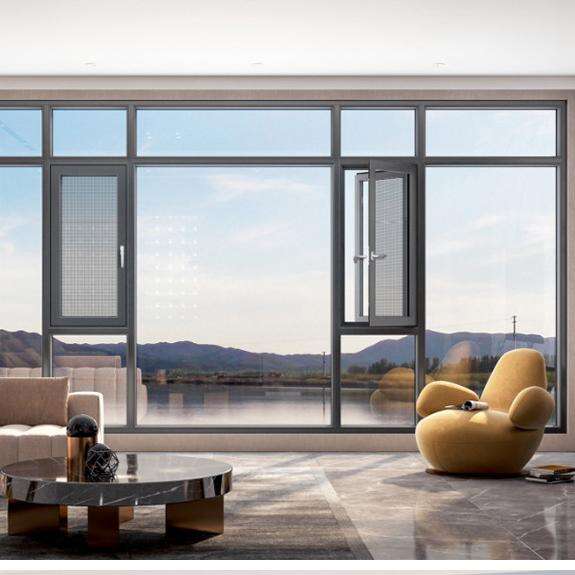

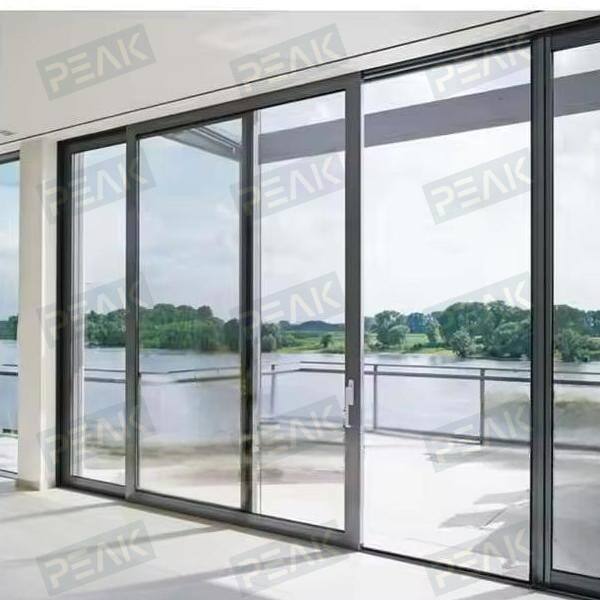

Aluminum door window manufacturing represents a sophisticated process that combines advanced engineering techniques with precision fabrication methods to create durable, aesthetic, and functional architectural solutions. This manufacturing sector specializes in producing high-quality aluminum-framed doors and windows that serve as essential components in residential, commercial, and industrial construction projects. The aluminum door window manufacturing process begins with the selection of premium-grade aluminum alloys, which are then subjected to extrusion processes to create profiles with specific dimensions and structural characteristics. These profiles form the backbone of door and window frames, providing exceptional strength-to-weight ratios that make aluminum an ideal material for architectural applications. The main functions of aluminum door window manufacturing encompass structural integrity, weather resistance, thermal efficiency, and aesthetic appeal. Modern manufacturing facilities utilize computer-controlled machinery to ensure precise cutting, drilling, and assembly of aluminum components. The technological features of contemporary aluminum door window manufacturing include powder coating systems that provide superior surface finishes, thermal break technology that enhances energy efficiency, and advanced glazing systems that optimize light transmission while maintaining security. Quality control measures throughout the aluminum door window manufacturing process ensure that each product meets stringent industry standards for performance and durability. The applications of aluminum door window manufacturing span across various sectors, including residential housing developments, commercial office buildings, retail establishments, educational institutions, healthcare facilities, and industrial complexes. These products are particularly valued in modern architecture for their ability to create expansive glass facades while maintaining structural integrity and energy efficiency.