casement sliding thermal break aluminum doors and windows factory

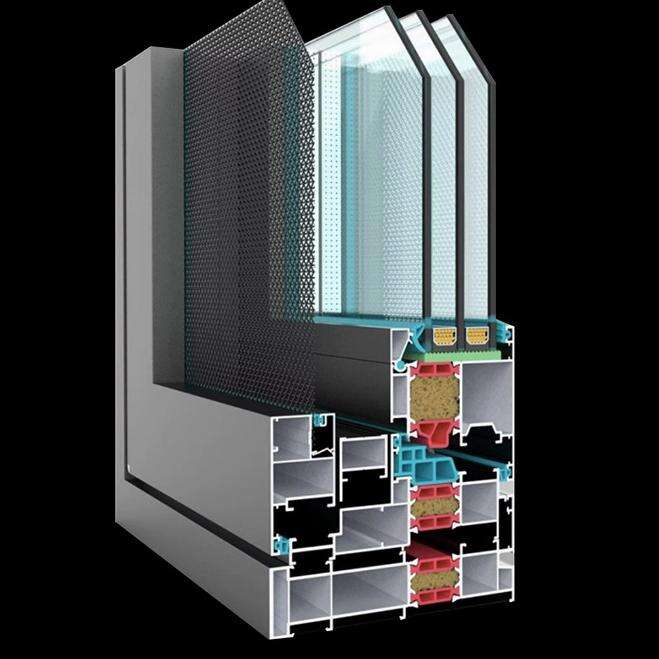

A casement sliding thermal break aluminum doors and windows factory represents the pinnacle of modern fenestration manufacturing, combining advanced engineering principles with cutting-edge production capabilities. These specialized facilities focus on creating high-performance window and door systems that integrate casement and sliding mechanisms with thermal break aluminum technology. The primary function of such a factory involves the precise fabrication of aluminum profiles that incorporate thermal barriers, preventing heat transfer between interior and exterior environments. These manufacturing centers utilize state-of-the-art machinery to cut, shape, and assemble aluminum frames with polyamide thermal breaks, creating energy-efficient openings for residential and commercial buildings. The technological features of a casement sliding thermal break aluminum doors and windows factory include automated cutting systems, precision welding equipment, and quality control stations that ensure each product meets stringent performance standards. Advanced powder coating lines provide durable finishes while maintaining the structural integrity of the aluminum components. The factory's production process integrates computer-controlled systems that optimize material usage and minimize waste, contributing to sustainable manufacturing practices. Applications of products from these facilities span across various sectors including residential construction, commercial buildings, hospitality projects, and institutional developments. The casement sliding thermal break aluminum doors and windows factory serves architects, contractors, and homeowners who demand superior thermal performance, durability, and aesthetic appeal in their building envelope solutions. These facilities typically maintain extensive inventory management systems to ensure timely delivery of custom and standard products, supporting both large-scale construction projects and individual renovation needs throughout diverse market segments.