Exceptional Durability and Weather Resistance for Long-Term Performance

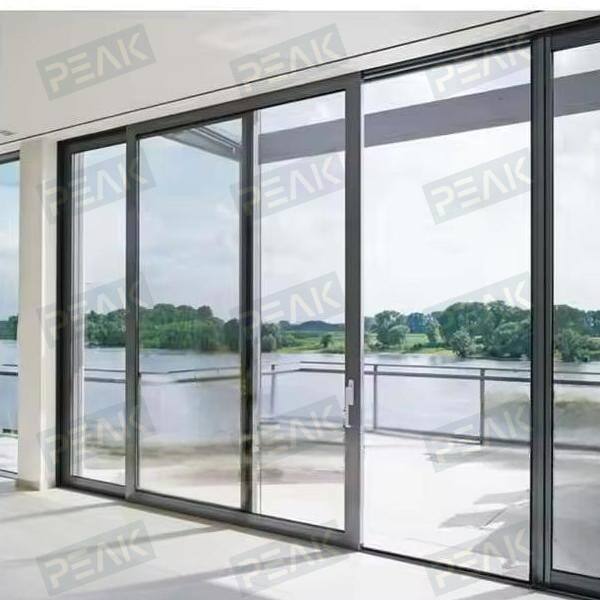

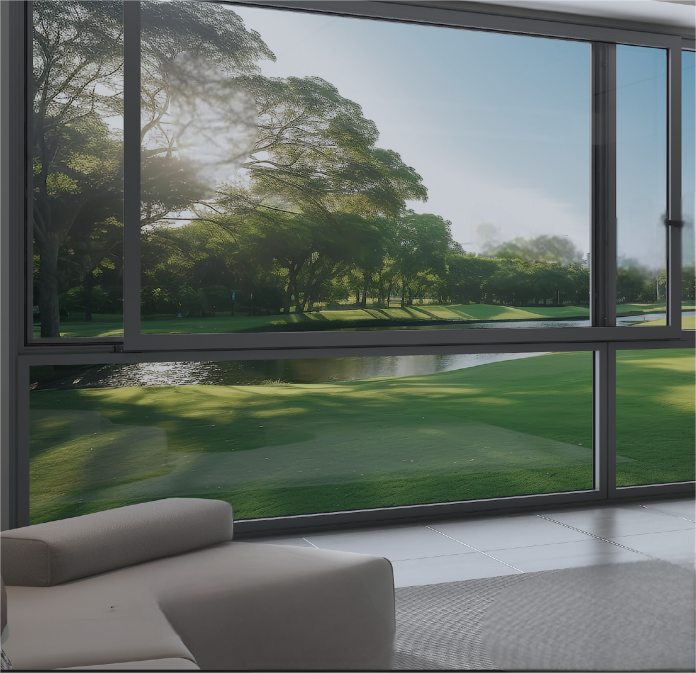

High quality heat insulation thermal break aluminum doors and windows deliver unmatched durability and weather resistance, ensuring reliable performance and aesthetic appeal for decades. Aluminum's inherent properties provide exceptional strength-to-weight ratios, corrosion resistance, and dimensional stability under varying environmental conditions. The extrusion process creates uniform, high-strength profiles that maintain structural integrity throughout their service life. Surface treatments including powder coating and anodizing provide additional protection against environmental factors while offering extensive design possibilities. Powder coating creates a durable, uniform finish that resists fading, chalking, and weathering, with color retention warranties extending 20 years or more. Anodizing produces an integral oxide layer that enhances corrosion resistance and provides distinctive metallic finishes. These surface treatments undergo rigorous testing including salt spray exposure, UV radiation, and thermal cycling to verify long-term performance. The thermal break components themselves demonstrate exceptional durability, with polyamide materials resisting degradation from temperature extremes, UV exposure, and chemical exposure. Structural testing verifies that high quality heat insulation thermal break aluminum doors and windows maintain performance under design loads, including wind pressure, thermal expansion, and operational stresses. Weather sealing systems incorporate advanced materials and designs that maintain effectiveness through repeated cycling and aging. Drainage systems prevent water accumulation while allowing thermal movement without compromising weather resistance. Hardware components utilize corrosion-resistant materials and finishes that coordinate with frame systems while providing smooth, reliable operation. The modular design facilitates component replacement when necessary, extending system life and maintaining performance standards. Fastening systems and structural connections accommodate thermal movement while maintaining weather sealing integrity. Quality manufacturing processes ensure consistent material properties and assembly precision that contribute to long-term reliability. Field performance data from installations in diverse climates confirms the exceptional durability of these systems, with minimal maintenance requirements and sustained performance over extended periods.